The first experiments on the creation of lithium galvanic cells were recorded back in 1012. A real working model was created in 1940, the first production copies (non-rechargeable!) Appeared in the 70s, and the triumphal procession of this type of battery began in the early 90s, when the Japanese company Sony was able to master their commercial production.

Currently, it is believed that this is one of the most promising directions for the creation of autonomous electrical energy sources despite their rather high (at the existing level) cost.

The main advantage of this type of battery is its high energy density (of the order of 100 W / h per 1 kg of weight) and the ability to perform a large charge / discharge cycle.

The newly created batteries are also characterized by such an excellent indicator as a low self-discharge rate (from 3 to 5% in the first month, with a subsequent decrease in this indicator). This allows for

And this is not all - in comparison with the widespread Ni-Cd, the new circuit with the same dimensions provides three times more performance with virtually no negative memory effect.

Negative characteristics

lithium ion batteries.

First of all, the high cost, the need to preserve the battery in a charged state, and the so-called “aging effect”, which manifests itself even when the galvanic cell was not in operation. The last unpleasant property is manifested in a constant decrease in capacity, which in two years can lead to a complete failure of the product.

Lithium batteries

Lithium or lithium-ion (Li-ion) batteries are mainly present in cell phones, laptops, and camcorders. Products are expensive, batteries, too, and therefore you need to deal with them even more competently than with any other batteries. So what is Li-Yon's strength? There are probably even more rumors and myths. Firstly, it starts to appear on its own, if only because sellers of equipment with Li-ion batteries do not give special parting words, saying that the battery is “smart” and will do everything right. But not myself. After all, how many cases have owners of new laptops worn out a battery in a month and then paid good ones for a new battery. Of course, lithium batteries are expensive because they are crammed with electronics, but, unfortunately, it does not save you from a fool.

Overdischarge

As with nickel batteries, lithium batteries are also very afraid of overcharging and overdischarging. But, since these batteries are used in smart devices and are equipped with their own chargers, their electronics do not allow overcharging - that is, you can not be afraid of him. But overdischarge is more difficult to control, which is why it is the most typical reason for premature battery failure. Of course, in expensive and complex devices, such as laptops, disconnection occurs before the voltage drops to a critical value. But precedents indicate that this emergency shutdown is better considered as an emergency measure, to which, if possible, it is better not to bring. This is the most important rule - to avoid complete discharge, as low voltage can disconnect the emergency protection circuit. It happens that people "kill" the battery, carried away by training. Training is a good thing, but for lithium batteries, 2-3 full cycles are enough.

There is no memory effect for lithium batteries, so they can be recharged at any time, so after training it is better not to discharge the batteries to the end. The recommended lower threshold is 5-10%. The critical lower threshold is 3%.

Many incomplete cycles or one complete

Lithium batteries have a lifespan of approximately 300 cycles. A full cycle is a cycle of full charge and full (i.e., up to about 3% capacity) discharge, or vice versa. If the battery is discharged to 50% and then charged, it will be 1/2 cycle, if up to 75% and charged - 1/4 cycle, etc. So, for phones and laptops, the difference in benefits between full and incomplete cycles is different. The Internet stubbornly claims that a lot of people charged their phones when they were not fully charged (that is, they recharged the phone every day) and, as a result, ditched them. At the same time, for laptops it is reliably known that full cycles wear out the battery faster than incomplete ones. The situation is clarified by a detailed examination of the device Li-ion batteries (see additional materials). It turns out a lot depends on the controller. It is he who controls the charge current, monitors the state of the battery, etc. So, in laptops, the controller is located in the battery itself and is adjusted by system utilities, such as calibration. In cell phones, the controller is located in the phone itself and so simply cannot be adjusted. Although lithium batteries do not have a memory effect, there is a so-called “digital memory" effect. The fact is that the charge-discharge control electronics located in the battery itself works independently of the device that uses the battery. Internal electronics monitors the cell voltage level, interrupts the charge upon reaching the set maximum value (taking into account the voltage change due to the charging current and battery temperature), interrupts the discharge when the critical value is reached and reports this “up” (a large range of specialized chips). The battery monitoring system “above” calculates the charge level based on information about the moments when the charge and discharge from the battery are turned off and the readings of the current measurement system. But if the operating conditions are such that a complete discharge before a hardware shutdown or a full charge does not occur, these calculations after several cycles may not be entirely correct - the battery capacity decreases over time, and the current meter readings may not always correspond to reality. Typically, deviations do not exceed one percent for each cycle, unless serious changes occur during operation, for example, with the failure of one of the battery cells. The monitoring system has the ability to “learn”, that is, to recalculate the value of the total battery capacity, but for this you need to perform at least one full charge-discharge cycle before the hardware circuits of the battery operate. So it turns out that with very frequent cycles, the controller crashes, and, therefore, incorrectly calculates the battery charge and performs incorrect charging, as a result of which the battery deteriorates. Unlike a laptop, you cannot recalibrate the phone. All that remains in this case is to make a couple of complete cycles to bring the controller in order. I recommend, ideally, combining complete and incomplete cycles, adhering to the principle of the “golden mean”. Personally, I did just that with my cell phone - as a result, after 2 years of operation, the drop in capacity was no more than 40%, which is the norm. In part, time also does not spare lithium batteries - they wear out over time, regardless of operation; their age is short and it is reasonable to change the batteries every 2-3 years.

Storage

If the battery is not used, it is recommended to store it at 40% capacity in a cool place. The lower temperature limit for storage and operation is 00 C. In general, lithium batteries like to be charged, i.e. they are better to store and keep in a charged state, unlike nickels. But with prolonged storage, the maximum charge still wears out the battery more, so 40% of the charge is considered the optimal state.

Battery resuscitation

In general, if the battery is dead, it is better to buy a new one, this is the most logical option, although expensive. I have not seen reliable recipes for reanimating batteries. There are real legends here, especially about laptops, that people reanimated their dying laptop battery and everything is fine with them. One of them sounds like this: “You need to completely discharge the battery, leave the laptop for a week; then fully charge the battery and also leave it for a week; after two months, the capacity should be restored. ”

For cell phones: combine full and incomplete cycles (in the proportion of "HZ").

For laptops: as few complete cycles as possible (after training).

For all: it is recommended to do 80% cycles; do not allow a full discharge (below 3%).

Lithium-ion (Li-ion) batteries, used in most modern tablets, smartphones and laptops, require different maintenance and operation rules compared to nickel-cadmium (Ni-Cd) and nickel-metal hydride (Ni-MH) batteries used in earlier devices.

In fact, proper care of a lithium-ion battery can increase its life by 15 times compared with improper use. This article gives tips on how to maximize the life cycle of costly lithium-ion batteries in all of your portable devices.

More recently, Fred Langa, a journalist for the Windows Secrets Internet portal, had to replace a damaged smartphone - and that was his mistake.

The main symptom did not bode well - the phone case was deformed, because the device’s body itself began to bend.

Upon analysis and detailed examination, it turned out that the smartphone’s battery was swollen.

Initially, Fred did not notice any changes: the battery looked more or less normal when viewed from its face (Figure 1). However, when the battery was laid on a flat surface, it became obvious that its upper and lower faces were no longer flat and parallel to each other. A serious bulge formed on one side of the battery (Figure 2). This bulge led to the fact that the phone began to bend and deform.

The bulge of the battery indicated a serious problem: the accumulation of toxic gases under high pressure inside the battery.

The battery case did a great job, but due to toxic gases, the battery was a tiny pressure cooker bomb that was just waiting for detonation.

In the case of Fred, both the phone and the battery were damaged - it is time to buy a new smartphone.

The saddest thing is that this problem could be easily prevented. In the final part of the article, Fred's errors will be given.

In order to avoid repeating the mistakes of the past with the new smartphone and other lithium-ion devices, such as tablets, laptops, Fred began to seriously study the proper operation and maintenance of lithium-ion batteries.

Fred was not interested in issues of extending the work on a single battery charge - these techniques are familiar. Most devices offer manual or automatic power-saving modes and methods for adjusting screen brightness, slowing processor performance, and reducing the number of running applications.

Rather, Fred focused on extending battery life — ways to keep the battery in good working order and extend battery life to the maximum level.

This article includes brief abstracts based on Fred's research. Follow the five suggested tips and then your lithium-ion batteries will work fully, long and safely in all your portable devices.

Tip 1: Monitor the temperature and do not overheat the battery

Surprisingly, heat is one of the main enemies of lithium-ion batteries. The causes of overheating of the battery may be factors of misuse, for example, the speed and duration of the charging and discharging cycles of the battery.

The external physical environment also matters. By simply leaving the device with a lithium-ion battery in the sun or in a closed car, you can significantly reduce the battery’s ability to receive and hold a charge.

Ideal temperature conditions for lithium-ion batteries is a room temperature of 20 degrees Celsius. If the device heats up to 30C, its ability to carry a charge is reduced by 20 percent. If the device is used at 45C, which is easily achievable in the sun or when the device is used intensively by resource-intensive applications, the battery capacity is reduced by about half.

Thus, if your device or battery becomes noticeably warm during use, try moving to a cooler place. If this is not possible, try to reduce the amount of energy consumed by the device by turning off unnecessary applications, services and functions, lowering the screen brightness, or activating the device’s power saving mode.

If this still does not help, completely turn off the device until the temperature returns to normal. For even faster cooling, remove the battery (of course, if the design of the device allows it) - this way the device cools faster due to physical separation from the power source.

By the way, despite the fact that high temperatures are the main problem with lithium-ion batteries, low-temperature operating modes do not cause serious concern. Low temperatures do not cause long-term damage to the battery, although a cold battery will not be able to deliver all the power that it can potentially give out at the optimum temperature. The power drop becomes very noticeable at temperatures below 4C. Most consumer-grade lithium-ion batteries essentially become useless at temperatures near or below freezing.

If a device with a lithium-ion power supply becomes excessively cooled for any reason, do not attempt to use it. Leave it unplugged and transfer it to a warm place (pocket or heated room) until the device reaches its normal temperature. Also, as in the case of overheating, physically remove the battery, and separate heating will speed up the heating process. After the battery warms up to normal temperature, its electrolytic properties will be restored.

Tip 2: Turn off the charger to save battery

Recharge - i.e. connecting the battery to a high voltage power source for too long can also reduce the battery’s ability to hold a charge, shorten its life or what is called “kill on the spot”.

Most consumer-grade lithium-ion batteries are designed to operate at a voltage level of 3.6V per cell, but operate at elevated 4.2V during charging. If the charger delivers excessive voltage for too long, the internal battery may be damaged.

In severe cases, recharging can lead to what engineers call “catastrophic” consequences. Even in moderate cases, the excess heat released during recharging will create a negative temperature effect, described in the first tip.

High-quality chargers can work in concert with the circuitry of modern lithium-ion batteries, reducing the risk of overcharging, reducing the charging current in proportion to the battery charge.

These properties vary significantly depending on the type of technology used in the battery. For example, when using nickel-cadmium (Ni-Cd) and nickel-metal hydride (Ni-MH) batteries, try to leave them connected to the charger for as long as possible. This is due to the fact that older types of batteries have a high level of self-discharge, i.e. they begin to lose a significant amount of stored energy immediately after disconnecting from the charger, even if the portable device itself is disconnected.

In fact, a nickel-cadmium battery can lose up to 10 percent of its charge in the first 24 hours after charging. After this period of time, the self-discharge curve begins to equalize, but the nickel-cadmium battery continues to lose 10-20 percent per month.

The situation with nickel metal hydride batteries is even worse. Their self-discharge rate is 30 percent higher than that of nickel-cadmium colleagues.

However, lithium-ion batteries have a very low self-discharge level. A good working battery will lose only 5 percent of its charge in the first 24 hours after charging and another 2 percent in the first month after that.

Thus, there is no need to leave the device with a lithium-ion battery connected to the charger until the last moment. For best results and extend battery life, unplug the charger when the full charge is shown.

New devices with lithium-ion batteries do not need to be charged continuously before first use (in devices with nickel-cadmium and nickel-metal hydride batteries, charging from 8 to 24 hours is recommended). Lithium-ion batteries are maximally charged when they show a 100 percent charge. Advanced charging is not necessary.

Not all discharge cycles affect battery condition in the same way. Prolonged and intensive use generates more heat, seriously loading the battery, and shorter, more frequent discharge cycles, on the contrary, extend the battery life.

You might think that increased cycles of small discharge / charge can seriously reduce the life of the power source. This was only natural for outdated technologies, but does not apply to modern lithium-ion batteries.

Battery specifications can be misleading since many manufacturers see the charge cycle as the time it takes to reach a 100 percent charge level. For example, two charges from 50 to 100 percent are equivalent to one full charge cycle. Similarly, three cycles of 33 percent or 5 cycles of 20 percent are also equivalent to one full cycle.

In short, a large number of small charge-discharge cycles do not reduce the total volume of cycles for a full charge of a lithium battery.

Again, heat and high load from heavy discharges reduce battery life. Therefore, try to reduce the number of deep discharges to a minimum. Do not let the battery level drop to values \u200b\u200bclose to zero (when the device itself turns off). Instead, consider the lower 15-20 percent of the battery charge as an emergency reserve - only in extreme cases. Get used to replacing the battery, if possible, or connecting the device to an external power source before the battery is completely discharged.

As you know, fast discharge and fast charging are accompanied by the release of excess heat and adversely affect the battery life.

If you have used the device intensively under heavy loads, allow the batteries to cool to room temperature before connecting to the charger. The battery will not be able to accept a full charge when heated.

While charging the device, monitor the temperature of the battery - it should not be too hot. A hot battery during charging usually indicates that too much current is flowing quickly.

Recharging is most likely with cheap unbranded chargers using fast charging circuits or with wireless (inductive) chargers.

A cheap charger can be an ordinary transformer with wires connected to it. Such “dumb charges" simply distribute the current and practically do not receive feedback from the charged device. Overheating and overvoltage are very common when using such chargers, which slowly destroys the battery.

“Quick” charges are designed to provide a minute charge, rather than a long hour charge. There are various approaches to fast charge technology, and not all of them are compatible with lithium-ion batteries. If the charger and battery are not designed to work together, fast charging can cause overvoltage and overheating. Generally speaking, it is better not to use a charger of one brand to charge a portable device of another brand.

Wireless (inductive) chargers use a special charging surface to restore battery power. At first glance, this is very convenient, but the fact is that such charges emit excess heat even in normal operation (Some stoves use the phenomenon of induction to heat pots and pans).

Lithium batteries not only experience a negative factor in the form of heat, but also spend energy while charging using wireless technology. By nature, the efficiency of an inductive charger is always lower than a conventional counterpart. Here everyone is free to make a choice on their own, but for Fred, increased heat and lower efficiency are sufficient factors to refuse such devices.

In any case, the safest approach is to use the supplied charger recommended by the manufacturer. This is the only guaranteed way to keep temperature and voltage within normal limits.

If it is not possible to use an OEM charger, use a device with a low output current to reduce the likelihood of battery damage due to the rapid arrival of high power.

One of the low output current power supplies is the USB port on a regular computer. The standard USB 2.0 port provides a current of 500mA (0.5A) per port, while USB 3.0 provides 900mA (0.9A) per port, respectively. For comparison, some special chargers can give out 3000-4000mA (3-4A). The low amperage of the USB ports generally guarantees safe charging with normal temperature conditions for most modern lithium-ion batteries.

Tip 5: If possible, use a spare battery

If your device allows you to quickly replace the battery, having a spare battery is great insurance. This not only doubles the operating time of the device, but also eliminates the need for a full battery discharge or the use of a quick charge. When the battery charge reaches 15-20 percent, just change the discharged battery to a spare one and you will instantly get a full charge of the device without any problems with overheating.

A spare battery has other advantages. For example, if you find yourself in a situation where the installed battery has overheated (for example, due to the intensive operation of the device or because of the high ambient temperature), you can change the hot battery to cool it faster and still use the device.

The presence of two batteries eliminates the need to use a fast charge - you can safely use the device when the battery is slowly charging from a safe power source.

Fred's Fatal Mistakes

Fred suggested that he might damage the smartphone’s battery while traveling. He used the GPS function in the device to navigate during a clear sunny day. The smartphone was in the sun for a long time in the holder in the area of \u200b\u200bthe car dashboard, the brightness of the smartphone was turned on to the maximum in order to distinguish the card from bright sunlight.

In addition, all standard background applications are email, instant messenger, etc. were launched. The device used a 4G module to download music tracks and a Bluetoorth wireless module to transfer sound to the car’s head sound device. The phone definitely worked under stress.

In order for the phone to receive power, it was connected to a 12V adapter, bought according to the criteria of a low price and the presence of the correct connector.

The combination of direct sunlight, high processor load, turned on at maximum screen brightness and dubious adapter quality, led to excessive overheating of the smartphone. Fred recalls with horror how hot the device was when pulled out of the holder. This severe overheating just became the catalyst for the death of the battery.

Apparently, the problem was aggravated at night, when Fred left the device connected to the network all night using a third-party charger, while not monitoring the moment the battery was fully charged.

With his new smartphone, Fred will only use an integrated charger and a spare battery. Fred hopes for a long and safe period of operation of both the battery and the phone, which he is going to achieve with the help of these tips.

Found a typo? Press Ctrl + Enter

Today, lithium-ion batteries are most commonly used in various fields. They are especially widely used in mobile electronics (PDAs, mobile phones, laptops, and much more), electric vehicles, and so on. This is due to their advantages compared to previously widely used nickel-cadmium (Ni-Cd) and nickel-metal hydride (Ni-MH) batteries. And if the latter came close to their theoretical limit, then lithium-ion battery technology is at the beginning of the journey.

Device

In lithium-ion batteries, aluminum acts as a negative electrode (cathode), and copper acts as a positive electrode (anode). The electrodes can be made in different forms, however, as a rule, this is a foil in the form of an elongated bag or cylinder.

- The anode material on the copper foil and the cathode material on the aluminum foil are separated by a porous separator, which is impregnated with an electrolyte.

- The electrode package is installed in a sealed enclosure, and the anodes and cathodes are connected to the current collector terminals

- There may be special devices under the battery cover. One device responds by increasing the resistance to a positive temperature coefficient. The second device breaks the electrical connection between the positive terminal and the cathode when the gas pressure in the battery rises above the permissible limit. In some cases, the casing is equipped with a safety valve that relieves internal pressure in case of abnormal operating conditions or emergency situations.

- To increase operational safety, a number of batteries also use external electronic protection. It does not allow the possibility of excessive heating, short circuit and overcharging the battery.

- Structurally, the batteries are produced in prismatic and cylindrical versions. The roll of the separator and electrodes in cylindrical batteries, rolled up in a roll, is placed in an aluminum or steel casing to which the negative electrode is connected. Through the insulator on the cover is the positive pole of the battery. Prismatic batteries are created by folding rectangular plates on top of each other.

Such lithium-ion batteries can provide denser packaging, but it is more difficult to maintain compressive forces on the electrodes than in cylindrical ones. A number of prismatic batteries use a roll assembly of a packet of electrodes twisted into an elliptical spiral.

Most of the batteries are produced in prismatic versions, since their main purpose is to ensure the operation of laptops and mobile phones. The design of Li-ion batteries is absolutely leakproof. This requirement is dictated by the inadmissibility of leakage of liquid electrolyte. If water vapor or oxygen gets inside, then a reaction occurs with the electrolyte and electrode materials, which leads to the complete failure of the battery.

Operating principle

- In lithium-ion batteries there are two electrodes in the form of an anode and a cathode, between them there is an electrolyte. At the anode, when the battery is connected in a closed circuit, a chemical reaction forms, which leads to the formation of free electrons.

- These electrons tend to get to the cathode, where their concentration is lower. However, their electrolyte, which is located between the electrodes, holds from the direct path to the cathode from the anode. The only way left is through the circuit where the battery closes. In this case, electrons moving along the indicated circuit feed the device with energy.

- The positively charged lithium ions that were left by the runaway electrons are sent through the electrolyte to the cathode, in order to satisfy the need for electrons on the cathode side.

- After moving all the electrons to the cathode, the "death" of the battery occurs. But the lithium-ion battery is rechargeable, that is, the process can be reversed.

Using a charger, you can let energy into the circuit, thereby starting the reaction of the flow in the opposite direction. As a result, an accumulation of electrons at the anode will be obtained. After recharging the battery, for the most part, it will remain so until it is put into operation. However, over time, the battery will lose some of its charge even in standby mode.

- Battery capacity refers to the amount of lithium ions that can invade craters and tiny pores of the anode or cathode. Over time, after numerous recharges, the cathode and anode degrade. As a result, the number of ions that they can accommodate is reduced. In this case, the battery can no longer hold the same amount of charge. In the end, he completely loses his functions.

Lithium-ion batteries are designed to be constantly monitored. For this purpose, a special board is installed in the case, it is called a charge controller. The chip on the board controls the battery charging process.

Standard battery charging is as follows:

- The controller at the beginning of the charging process supplies a current of 10% of the nominal. At the moment, the voltage rises to 2.8 V.

- Then the charge current rises to the nominal. During this period, the DC voltage rises to 4.2 V.

- At the end of the charging process, the current drops at a constant voltage of 4.2 V until the battery is 100% charged.

The phasing may vary due to the use of different controllers, which leads to different charging speeds and, accordingly, the total cost of the battery. Lithium-ion batteries can be without protection, that is, the controller is located in the charger, or with built-in protection, that is, the controller is located inside the battery. There may be devices where the protection board is built directly into the battery.

Varieties and applications

There are two form factors for lithium-ion batteries:

- Cylindrical lithium-ion batteries.

- Tablet lithium-ion batteries.

The different subspecies of the electrochemical lithium-ion system are named according to the type of active substance used. What unites all these lithium-ion batteries is that they are all sealed, maintenance-free batteries.

You can cite the 6 most common types of lithium-ion batteries:

- Cobalt lithium battery . It is a popular solution for digital cameras, laptops and mobile phones in view of the high specific energy consumption. The battery consists of a cathode of cobalt oxide and a graphite anode. Disadvantages of lithium-cobalt batteries: limited load capacity, low thermal stability and relatively short service life.

Areas of use ; mobile electronics.

- Lithium manganese battery . The cathode of crystalline lithium-manganese spinel stands out three-dimensional frame structure. Spinel provides low resistance, but differs in more moderate specific power consumption, than cobalt.

Areas of use; electric power units, medical equipment, power tools.

- Lithium nickel manganese cobalt oxide battery . The cathode of the battery combines cobalt, manganese and nickel. Nickel is famous for its high specific energy consumption, but low stability. Manganese provides low internal resistance, but leads to low specific energy consumption. The combination of metals allows you to compensate for their cons and harness the strengths.

Areas of use; for private and industrial use (security systems, solar power plants, emergency lighting, telecommunications, electric cars, electric bicycles and so on).

- Lithium iron phosphate battery . Its main advantages: long service life, high current strength, resistance to misuse, increased safety and good thermal stability. However, such a battery has a small capacity.

Scopes; stationary and portable specialized devices where endurance and high load currents are necessary.

- Lithium nickel-cobalt-aluminum-oxide battery . Its main advantages: high energy density and energy intensity, durability. However, safety indicators and high cost limit its use.

Areas of use; electric power units, industry and medical equipment.

- Lithium titanate battery . Its main advantages: fast charging, long service life, wide temperature range, excellent performance and safety. This is the safest lithium-ion battery.

However, it has a high cost and low specific energy consumption. Currently, developments are underway to reduce the cost of production and increase specific energy consumption.

Areas of use; street, electric power units of cars (Honda Fit-EV, Mitsubishi i-MiEV), UPS.

Typical characteristics

In general, lithium-ion batteries have the following typical characteristics:

- The minimum voltage is not lower than 2.2-2.5V.

- The maximum voltage is not higher than 4.25-4.35V.

- Charge time: 2-4 hours.

- Self-discharge at room temperature - about 7% per year.

- Operational temperature range from −20 ° C to +60 ° C.

- The number of charge / discharge cycles until a loss of 20% capacity is achieved is 500-1000.

Advantages and disadvantages

The benefits include:

- High energy density when compared with alkaline batteries using nickel.

- Sufficiently high voltage of one battery cell.

- The absence of a “memory effect", which ensures easy operation.

- A significant number of charge-discharge cycles.

- Long term of operation.

- Wide temperature range for consistent performance.

- Relative environmental safety.

Among the shortcomings can be identified:

- Moderate discharge current.

- Relatively fast aging.

- Relatively high cost.

- Inability to work without a built-in controller.

- The probability of spontaneous combustion at high loads and with too deep a discharge.

- The design requires significant improvements, because it is not brought to perfection.

For a long time, an acid accumulator was the only device capable of providing autonomous objects and mechanisms with electric current. Despite the large maximum current and minimum internal resistance, such batteries had a number of drawbacks that limited their use in devices consuming a large amount of electricity or in enclosed spaces. In this regard, lithium-ion batteries are devoid of many negative qualities of their predecessors, although they have drawbacks.

Content

What is a lithium ion battery

The first lithium batteries appeared 50 years ago. Such products were an ordinary battery in which a lithium anode was installed to increase the level of power output. Such products had very high operational characteristics, but one of the most serious drawbacks was the high probability of lithium ignition during cathode overheating. Given this feature, scientists have over time replaced the pure element with metal ions, resulting in significantly increased safety.

Modern li-ion batteries are very reliable and able to withstand a large number of charge-discharge cycles. They have a minimal memory effect and relatively low weight. Due to these properties, a lithium battery is widely used in many devices. The product can be used as a battery, in the form of batteries for household appliances, as well as a highly efficient traction power source.

Today, such devices have several disadvantages:

- high cost;

- do not like deep discharges;

- may die at low temperatures;

- lose capacity when overheating.

How is the production of li-ion batteries

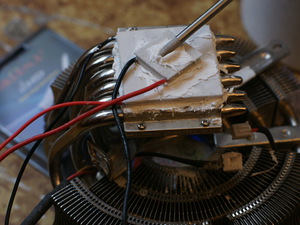

Lithium-ion batteries are produced in several stages:

- The manufacture of electrodes.

- Combining electrodes into a battery.

- Installing the protection board.

- Install the battery in the case.

- Electrolyte filling.

- Testing and charge.

At all stages of production, technology and safety measures must be followed, which ultimately allows you to get a quality product.

As a cathode in lithium-ion batteries, a foil is used with a substance containing lithium deposited on its surface.

The following lithium compounds can be used, depending on the purpose of the battery:

- LiCoO2;

- LiNiO2;

- LiMn2O4.

In the manufacture of cylindrical power sources of sizes AA and AAA, the main electrode is twisted into a roll, which is separated from the anode by a separator. With a large area of \u200b\u200bthe cathode, the film of which has a minimum thickness, it is possible to achieve high energy intensity of the product.

The principle of operation and device li-ion battery

The lithium-ion battery operates as follows:

- When a constant electric current is supplied to the battery contacts, lithium cations move into the anode material.

- During discharge, lithium ions leave the anode and penetrate the dielectric to a depth of 50 nm.

In the “life” of a lithium-ion battery, such cycles can be up to 3,000, while the battery can give off almost all the electric current accumulated during charging. Deep discharge does not lead to oxidation of the plates, which favorably distinguishes such products in comparison with acid batteries.

Not all li-ion batteries tolerate deep discharges well. If such a battery is installed in the phone or camera (type AAA), then when the battery is deeply discharged, the controller board will block the possibility of charging the battery for safety reasons, therefore, it cannot be charged without a special charger. If this is a traction lithium battery for an outboard motor, then a deep discharge will not be at all frightening to it.

Unlike finger-type batteries, complex batteries consist of several separate sources of electricity connected in parallel or in series. The connection method depends on what indicator of electricity needs to be increased.

Sizes and types of li-ion batteries

Lithium-ion batteries are widespread. Such sources of electric current are used in various household devices, gadgets and even cars. In addition, industrial lithium-ion batteries are manufactured, which have a large capacity and high voltage. The most popular are the following types of lithium batteries:

| Title | Diameter mm | Long mm | Capacity mAh |

|---|---|---|---|

| 10180 | 10 | 18 | 90 |

| 10280 | 10 | 28 | 180 |

| 10440 (AAA) | 10 | 44 | 250 |

| 14250 (AA / 2) | 14 | 25 | 250 |

| 14500 | 14 | 50 | 700 |

| 15270 (CR2) | 15 | 27 | 750-850 |

| 16340 (CR123A) | 17 | 34.5 | 750-1500 |

| 17500 (A) | 17 | 50 | 1100 |

| 17670 | 17 | 67 | 1800 |

| 18500 | 18 | 50 | 1400 |

| 18650 (168A) | 18 | 65 | 2200-3400 |

| 22650 | 22 | 65 | 2500-4000 |

| 25500 (type C) | 25 | 50 | 2500-5000 |

| 26650 | 26 | 50 | 2300-5000 |

| 32600 (type D) | 34 | 61 | 3000-6000 |

The first two digits of such designations indicate the diameter of the product, the second pair - the length. The last “0” is set if the batteries are cylindrical.

In addition to cylindrical-shaped batteries, the industry also produces “” type batteries with a voltage of 9v and powerful industrial batteries with a voltage of 12v, 24v, 36v and 48v.

Stacker battery

Stacker battery Depending on the elements that are added to the product, the following markings may appear on the battery case:

- ICR - containing cobalt;

- IMR - - - - manganese;

- INR - - - - nickel and manganese;

- NCR - - - - nickel and cobalt.

Lithium batteries differ not only in size and chemical additives, but primarily in capacity and voltage. These two parameters determine the possibility of their use in various types of electrical appliances.

Where are li-ion batteries used?

Lithium-ion batteries have no alternative where you need a battery capable of delivering electricity in almost full volume, and to perform a large number of charge / discharge cycles without reducing capacity. The advantage of such devices is their relatively low weight, because there is no need to use lead grids in such devices.

Given the high performance characteristics, such products can be used:

- As starter batteries. Lithium batteries for cars are getting cheaper every year, thanks to new developments that can reduce production costs. Unfortunately, the price of such batteries can be very high, which is why many car owners cannot afford such a battery. The disadvantages of lithium-ion batteries include a significant drop in power at temperatures below minus 20 degrees, so the operation of such products in the northern regions will be impractical.

- As traction devices. Due to the fact that lithium-ion batteries easily carry a deep discharge, they are often used as traction for boat electric motors. If the engine power is not too large, then one charge is enough for 5-6 hours of continuous operation, which is quite enough for fishing or taking a boat trip. Traction lithium-ion batteries are also installed on various loading equipment (electric stackers, electric forklifts) operating in enclosed spaces.

- In household appliances. Lithium-ion batteries are used in various household devices instead of standard batteries. Such products have a voltage of 3.6v - 3.7v, but there are models that can replace a regular salt or alkaline battery with 1.5 Volts. You can also meet 3v batteries (15270,), which can be installed instead of 2 standard batteries.

Such products are used mainly in powerful devices in which conventional salt batteries discharge very quickly.

Traction Battery

Traction Battery Li ion battery operating instructions

The life of a lithium battery is influenced by many factors, the knowledge of which will significantly increase the resource. When using this type of battery, you must:

- Try not to let the battery run out completely. Despite the high resistance of the battery to such an impact, it is advisable not to squeeze all the “juices” out of it. Particular care should be taken when operating such batteries with UPS and high power electric motors. If a full discharge of the battery has occurred, it is necessary to immediately revive it, that is, connect it to a special charger. You can also recharge the battery after a long stay in a deep discharge state, for which it is necessary to make a high-quality charge for 12 hours, then discharge the battery.

- Do not overcharge. Overcharging negatively affects product performance. The built-in controller is not always able to turn off the battery in time, especially when charging is carried out in a cold room.

In addition to overcharging and over-discharging, the battery should be protected from excessive mechanical influences, which can lead to depressurization of the case and fire to the internal components of the battery. For this reason, there is a prohibition on mailing batteries in which the content of pure lithium exceeds 1 g.

Used as a battery for screwdrivers, laptops and phones

Used as a battery for screwdrivers, laptops and phones How to store lithium-ion batteries

If there is a need for long-term storage of lithium-ion batteries, then to minimize the negative impact on the products, you must adhere to the following recommendations:

- Store the product only in a cool, dry place.

- The battery must be removed from the electrical device.

- The battery must be charged before preservation. The minimum voltage at which internal corrosion processes will not form is equal to 2.5 volts per 1 cell.

Given the small self-discharge of such batteries, it is possible to store the battery in this way for several years, but during this period the capacity of the cell will inevitably decrease.

Disposal of lithium-ion batteries

Lithium-ion batteries contain substances hazardous to health, so in no case should they be taken apart at home. After the battery runs out of life, it must be returned for further processing. In specialized reception centers, you can receive monetary compensation for an old lithium battery, because such products contain expensive elements that can be reused.