Batteries

What current to charge li ion 18650 battery? How to properly operate such a battery. What are lithium-ion current sources afraid of and how can such a battery extend its life? Similar questions may arise in a wide variety of electronics industries.

And if you decide to personally assemble your first flashlight or electronic cigarette, then you definitely need to familiarize yourself with the rules for working with similar current sources.

A lithium-ion battery is a type of electric current battery that, since 1991, after the company SONY introduced it to the market, has gained widespread adoption in modern household and electronic appliances. As a power source, such batteries are used in cell phones, laptops and camcorders, as a current source for electronic cigarettes and electric vehicles.

The disadvantages of this type of battery begin with the fact that first-generation lithium-ion batteries were an explosion in the market. Not only literally, but also figuratively. These batteries exploded.

This was explained by the fact that an anode of metallic lithium was used inside. In the process of numerous charges and discharges of such a battery, spatial formations appeared on the anode, which led to the closure of the electrodes, and as a result to a fire or explosion.

After this material was replaced with graphite, a similar problem was eliminated, but problems could still arise at the cathode, which was made of cobalt oxide. In case of violation of operating conditions, or rather recharging, the problem could recur. This was fixed with the beginning of the use of lithium-ferro-phosphate batteries.

All modern lithium-ion batteries prevent overheating and overcharging, but there remains the problem of loss of charge at low temperatures when using the devices.

Among the indisputable advantages of lithium-ion batteries, I would like to note the following:

- high battery capacity;

- low self-discharge;

- lack of need for maintenance.

Original Chargers

The charger for lithium-ion batteries is pretty similar to the charger for lead-acid batteries. The only difference is that the lithium-ion battery has very high voltages on each bank and more stringent voltage tolerance requirements.

Such a battery is called a can because of the external similarity with aluminum cans for drinks. The most common battery of this form is the 18650. The battery got this designation due to its size: 18 millimeters in diameter and 65 millimeters in height.

If for lead-acid batteries some inaccuracies are indicated in the indication of the boundary stresses during charging, with lithium-ion cells everything is much more specific. During charging, when the voltage rises to 4.2 Volts, the voltage supply to the cell should stop. Allowable error of only 0.05 volts.

Chinese charging, which can be found on the market, can rely on batteries on different materials. Li-ion, without prejudice to its performance, can be charged with a current of 0.8 A. In this case, you need to carefully monitor the voltage on the bank. It is advisable not to allow values \u200b\u200babove 4.2 volts. If there is a controller in the assembly with the battery, then you should not worry about anything, the controller will do everything for you.

The most ideal charger for lithium-ion batteries will be a voltage stabilizer and current limiting at the beginning of the charge.

Lithium needs to be charged with a stable voltage and current limitation at the beginning of the charge.

Homemade Charger

To charge the 18650, you can buy a universal charger, and do not worry about how to check the necessary parameters with a multimeter. But such an acquisition will fly you a pretty penny.

The price of such a device will vary around $ 45. But you can still spend 2-3 hours and assemble the charger yourself. Moreover, this charger will be cheap, reliable and will automatically turn off your battery.

Every radio amateur has the parts that we will use today to create our charger. If you didn’t have a radio amateur with the necessary parts at hand, then on the radio market you can buy all the parts for no more than 2-4 dollars. The circuit, which is assembled correctly and neatly mounted, starts working immediately and does not need any additional debugging.

The electric circuit of the battery charge 18650.

In addition to this, when installing the stabilizer on a suitable radiator, you can safely put your batteries to charge without fear that the charge will overheat and light up. What can not be said about Chinese chargers.

The circuit works quite simply. First, the battery must be charged with direct current, which is determined by the resistance of the resistor R4. After the battery has a voltage of 4.2 Volts, charging with a constant voltage begins. When the charging current drops to very small values, the LED in the circuit will turn off.

The currents recommended for charging lithium-ion batteries should not exceed 10% of the battery capacity. This will increase the life of your battery. With a resistor rating of R4 - 11 Ohms, the current in the circuit will be 100 mA. If you use a resistance of 5 ohms, then the charging current will be already 230 mA.

How to extend the life of your 18650

Disassembled battery.

If you have to leave your lithium-ion battery for some time without work, it is better to store the batteries separately from the device that they power. A fully charged element will lose part of its charge over time.

An element that is charged very little, or completely discharged, can permanently lose working capacity after prolonged hibernation. Optimal would be storing the 18650 at a charge level of about 50 percent.

Do not allow a complete discharge and overcharge of the element. Lithium-ion batteries have completely no memory effect. It is advisable to charge such batteries until the moment when their charge is completely exhausted. This is also able to extend the battery performance.

Lithium-Ion do not like neither heat nor cold. The optimal temperature conditions for these batteries will be a range from +10 to +25 degrees Celsius.

Cold can not only reduce the operating time of an element, but also destroy its chemical system. I think each of us noticed how the charge level in a mobile phone quickly drops in the cold.

Output

Summarizing all of the above, I want to note that if you are going to charge a lithium-ion battery with a store-made charger, pay attention to the fact that this is not a Chinese production. Very often, these chargers are assembled from cheap materials and the necessary technology is not always observed in them, which can lead to undesirable consequences in the form of fires.

If you want to assemble the device yourself, then you need to charge the lithium-ion battery with a current that will be 10% of the battery capacity. The maximum may be a figure of 20 percent, but this value is already undesirable.

When using such batteries, it is worth observing the rules of operation and storage in order to exclude the possibility of an explosion, for example, from overheating, or failure.

Compliance with the conditions and rules of operation will extend the life of the lithium-ion battery, and as a result will save you from unnecessary financial costs. The battery is your assistant. Take care of her!

Most modern gadgets receive power in two ways: from the network, from batteries. Which one do you choose? Probably the second, as the most convenient. But then you have to take care of their regular charge. For this, there is special equipment - a charger for lithium-ion batteries. Choosing it, they are usually interested in the speed of charge and the number of simultaneously restored batteries.

But at the same time, do not forget that it should be optimized to work with specific batteries. Most foreign battery manufacturers also produce their own chargers, which saves you from the tedious search for a suitable model. What is their difference and how to navigate this sea of \u200b\u200bproducts? Now we will tell in more detail.

Charging for finger batteries

This device is a necessary item for people who prefer an active lifestyle, who have transferred the maximum number of gadgets used to work on batteries. One of the most common among such devices is a mobile phone.

This device is a necessary item for people who prefer an active lifestyle, who have transferred the maximum number of gadgets used to work on batteries. One of the most common among such devices is a mobile phone.

All are equipped with lithium-based batteries. Therefore, it is recommended that they purchase a charger for the 18650 lithium battery. As an attempt to restore the battery capacity using an inappropriate model, it will damage it.

Typically, devices marked with EP are used to charge lithium-based batteries. In a mobile phone, the battery is considered the most vulnerable spot. And if you use the wrong charge, its service life may be reduced, it will quickly discharge, which will deliver a lot of uncomfortable moments. To avoid this, it is necessary to choose the right equipment for recovery. Moreover, it is not necessary to purchase a finished model; you can make a charger for lithium batteries with your own hands. Such a device will cost less than an industrial product.

Design features of memory

The classic charger circuit for the 18650 lithium battery includes two main parts:

- Transformer;

- Rectifier.

It is used to generate direct current with a voltage of 14.4V. This parameter value was not chosen randomly. It is necessary so that current can pass through a discharged battery. And since at this time the battery voltage is about 12V, it is impossible to charge it with a device that has the same value at the output. That's why the value of 14.4V was chosen.

The principle of operation of the memory

Battery capacity recovery starts when the charger is turned on. In this case, the internal resistance of the battery increases, and the current decreases. As soon as the battery voltage reaches the 12V mark, the current will approach the zero mark. Such parameters indicate that the battery was charged successfully and the device can be turned off.

In addition to the usual process, which takes quite a long time, there is also an accelerated one. Rapid charging significantly reduces the time, but at the same time negatively affects the battery, so experts do not recommend using this method.

Criteria for choosing a charging device

You can determine how high quality the purchased device can be by the following points:

- The presence of independent charge channels;

- Toku;

- Discharge functions.

Let's consider each of them in detail. Let's start with the most significant - independent charge channels. The presence of them in the selected model suggests that its electronic filling is able to separately control the charging process and stop it as soon as the battery capacity is restored. But at the same time, everyone else will not have time to restore their capacity, which, with a constant repetition of such a situation, leads to the rapid failure of the batteries.

Recharging battery power is possible in three ways:

- Low current;

- Average;

- High.

The first involves the choice of a charger for lithium-ion batteries, taking into account the nominal battery capacity. At the same time, the current generated by it should not exceed 10%. This method of charging is the slowest and most gentle. With its constant use, the battery life is practically not reduced.

The use of devices with a current of less than half the nominal capacity of the battery is considered the middle ground. With it, the battery practically does not heat up and the cycle time is not very long, as in the first case.

The last method or charging with a large current almost equal to the nominal capacity is a kind of stress for the battery, leading to a significant reduction in the service life. With it, strong heating occurs, requiring active fan cooling. It is used only in extreme cases when you need to charge the battery in a couple of hours.

Watch a video review of injection molding chargers:

There are so-called smart devices. They are used to charge batteries by professional photographers used in lighting fixtures and other similar cases. The cost of such a charger for lithium-ion batteries is quite high, but if the gadget's flawless operation is important to you, then it is better to invest in the purchase of the device than to constantly change the batteries.

Smart chargers have a discharge function. It is necessary to completely discharge the battery, thereby eliminating the memory effect. This slightly lengthens the charging cycle, but thereby extends the battery life.

Some models also have a training function. It is used to return partially damaged batteries to working condition.

Top manufacturers

Each product has its own characteristics. Therefore, choosing a specific brand, you must first focus on the number and type of batteries that will have to be charged. If you plan to work with 4 batteries, then you can stop at the Rodition Ecocharger model. This is a small device that can recover even disposable alkaline batteries. The inclusion of this function is a toggle switch located on the side panel of the housing.

The device has four channels and is able to control the charge level of each element separately. The device panel has a light indication showing which of the batteries has already recovered. You can buy such a device for $ 20.

Watch a video about Rodition Ecocharger products:

One of the most popular and multi-functional is considered a charger for lithium batteries of the brand La Crosse BC-700. It belongs to the advanced ones and is designed for the restoration of finger AAA and AAA nickel-based formats. The features of the device are such that it is capable of simultaneously charging 4 batteries of different capacities.

The device operates in several modes. There is a current regulator that allows you to choose the most optimal value for each case.

Charging Stages

Experts recommend starting the battery recovery process with a full discharge. If for some reason you have to charge a battery that has not yet fully discharged, then you should choose an advanced model of the device.

Batteries play an important role in any non-mains mechanism. Rechargeable batteries are quite expensive, due to the fact that you need to purchase a charger with them. A variety of combinations of conductive materials and electrolytes are used in batteries - lead-acid, nickel-cadmium (NiCd), nickel-metal hydride (NiMH), lithium-ion (Li-ion), lithium-ion polymer (Li-Po).

I use lithium-ion batteries in my projects, so I decided to do the charging for the 18650 lithium batteries with my own hands, rather than buying expensive, so let's get started.

Step 1: Video

The video shows the assembly of the charger.

Youtube link

Step 2: List of Electrical Components

Show 3 more images

List of components required to assemble a 18650 battery charger:

- Charger module based on TP4056 chip with battery protection

- 7805 voltage regulator, you will need 1 pc

- Capacitor 100 nF, 4 pcs (not needed if there is a 5V power supply)

Step 3: Tool List

For work you will need the following tools:

- Hot knife

- Plastic box 8x7x3 cm (or close in size)

Now that all the necessary tools and components are ready for work, we will deal with the TP4056 module.

Step 4: TP4056 Chip Li-io Battery Charger Module

A bit more about this module. The market offers two options for these modules: with and without battery protection.

A circuit board containing a protection circuit monitors the voltage using the power supply filter DW01A (battery protection integrated circuit) and FS8205A (N-channel transistor module). Thus, the circuit board contains three integrated circuits (TP4056 + DW01A + FS8205A), while the charger module without battery protection contains only one integrated circuit (TP4056).

TP4056 is a charge module for single-cell Li-io batteries with a linear charge of direct current and voltage. The SOP housing and the small number of external components make this module an excellent option for use in home-made electrical appliances. It charges via USB as well as through a conventional power supply. The pinout of the TP4056 module is attached (Fig. 2), as well as the graph of the charging cycle (Fig. 3) with DC and DC voltage curves. Two diodes on the circuit board show the current charge status - charge, charge termination, etc. (Fig. 4).

In order not to damage the battery, the charge of 3.7 V lithium-ion batteries should be carried out at a constant current value of 0.2-0.7 from their capacity until the output voltage reaches 4.2 V, after which the charge will be carried out by a constant voltage and gradually decreasing (up to 10% of the initial value) current. We can not interrupt the charge at a voltage of 4.2 V, since the charge level will be 40-80% of the total battery capacity. The TP4056 module is responsible for this process. Another important point - the resistor connected to the PROG pin determines the charging current. In the modules on the market, a 1.2 KΩ resistor is usually connected to this output, which corresponds to a charging current of 1A (Fig. 5). To get other values \u200b\u200bof the charging current, you can try to put other resistors.

DW01A is an integrated circuit for battery protection; Fig. 6 shows a typical connection diagram. MOSFETs M1 and M2 are connected externally by the integrated circuit FS8205A.

These components are installed on the circuit board of the TP4056 lithium-ion battery charge module, the link to which is in Step 2. We only need to do two things: give a voltage in the range of 4-8 V to the input connector, and connect the battery terminals to the + and - terminals TP4056 module.

After that, we continue to assemble the charger.

Step 5: wiring diagram

To complete the assembly of electrical components, we solder them in accordance with the scheme. I attached a diagram in the Fritzing program and a photo of the physical connection.

- + connect the contact of the power connector to one of the contacts of the switch, and - connect the contact of the power connector to the GND pin of the stabilizer 7805

- The second contact of the switch is connected to the Vin pin of the stabilizer 7805

- We install three 100 nF capacitors in parallel between the Vin and GND pins of the voltage regulator (for this, use a breadboard)

- Install a 100 nF capacitor between the Vout and GND pins of the voltage regulator (on the breadboard)

- Connect the Vout pin of the voltage regulator to the IN + pin of the TP4056 module

- Connect the GND pin of the voltage regulator to the IN-pin of the TP4056 module

- Connect + the contact of the battery compartment with the B + pin of the TP4056 module, and - connect the contact of the battery compartment with the B- pin of the TP4056 module

On this connection are completed. If you use a 5 V power supply, skip all the items connected to the voltage regulator 7805, and connect the + and - of the unit directly to the IN + and IN- pins of the TP4056 module, respectively.

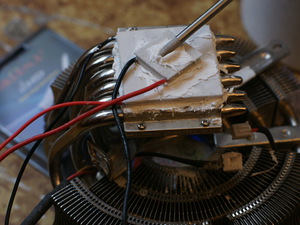

If you use a 12V power supply, when the current passes 1A, the 7805 stabilizer will heat up, this can be fixed by a heat sink.

Step 6: Assembly, Part 1: Cut holes in the housing

Show 7 more images

In order to properly fit all the electrical components in the housing, you need to cut holes in it:

- Mark the borders of the battery compartment on the case with a knife blade (Fig. 1).

- Cut a hole with a hot knife along the marks made (Fig. 2 and 3).

- After cutting a hole, the case should look like in Fig. 4.

- Mark the place where the USB connector of the TP4056 module will be located (Fig. 5 and 6).

- With a hot knife, cut a hole in the housing for the USB connector (Fig. 7).

- Mark the places on the case where the diodes of the TP4056 module will be located (Fig. 8 and 9).

- Cut a hole with a hot knife under the diodes (Fig. 10).

- In the same way, make holes for the power connector and switch (Fig. 11 and 12)

Step 7: Assembly, Part 2: Installing Electrical Components

Follow the instructions to install the components in the enclosure:

- Install the battery compartment so that the mounting points are outside the compartment / housing. Glue the compartment with a glue gun (Fig. 1).

- Replace the TP4056 module so that the USB connector and the diodes get into the corresponding holes, fix with hot glue (Fig. 2).

- Replace the voltage regulator 7805, fix with hot glue (Fig. 3).

- Replace the power connector and switch, fix them with hot glue (Fig. 4).

- The location of the components should look the same as in Fig. 5.

- Fasten the bottom cover in place with screws (fig. 6).

- Later, I covered the bumps left by the hot knife with black electrical tape. They can also be smoothed out with sandpaper.

The completed charger is shown in Fig. 7. now it needs to be tested.

Step 8: Test

Insert a discharged battery into the charger. Turn on the power to the 12V or USB connector. The red diode should blink, which means that the charge process is in progress.

When the charge is complete, the blue diode should light up.

I attach a photo of the charger in the process of charging and a photo with a charged battery.

On this work is completed.

Charger for li ion batteries, the scheme of which is given in this article, was developed on the basis of the experience of designing such chargers, efforts to eliminate errors and achieve maximum simplicity. The charger is highly stable output voltage.

Charging description for lithium-ion batteries

The main structural element is (IO1), a voltage reference source. Its stability is much better than acceptable, and, as is known for lithium-ion batteries, this is a very important characteristic when charging.

The TL431 element is used in this circuit as a current stabilizer in the operation of transistors T1 and T2. Charging current flows through R1. If the voltage drop across this resistor exceeds approximately 0.6 volts, the current passing through the transistors T1 and T2 is limited. The value of resistor R1 is equivalent to the charging current.

The output voltage is controlled by the aforementioned TL431 element. The value is determined by the output voltage divider (R5, R7, P1).

Components R4, C1 for noise suppression. It is very convenient to indicate the magnitude of the charging current using the LED1. The glow shows what current flows in the base circuit of the transistor T2, which is proportional to the output current. As the lithium-ion battery is charging, the brightness of the LED gradually decreases.

Diode D1 is designed to prevent the discharge of a lithium-ion battery in the absence of voltage at the input of the charger. The battery charging circuit does not need protection against incorrect polarity of the li-ion battery.

All components are placed on a single-sided printed circuit board.

Current sensor - resistor R1 consists of several resistors connected in parallel. Transistor T2 must be placed on the heat sink. Its size depends on the charging current and the voltage difference between the input and output of the charger.

Current sensor - resistor R1 consists of several resistors connected in parallel. Transistor T2 must be placed on the heat sink. Its size depends on the charging current and the voltage difference between the input and output of the charger.

The charger circuit of a lithium-ion battery is so simple that with proper installation of radio components it should work the first time. The only thing that may be required is the installation of the output voltage. For a lithium-ion battery, this is approximately 4.2 volts. When idle, transistor T2 should not be hot. The input voltage must be at least 2 volts higher than the required output voltage.

The circuit is designed for charging current up to 1 ampere. If you need to increase the charge current of the li-ion battery, then it is necessary to reduce the resistance of the resistor R6 and the output transistor T2 must be of increased power.

At the end of the charging process, the LED still glows a little, in order to eliminate this, you can simply connect a 10 ... 56 kΩ resistor in parallel with the LED. So when the charge current drops below 10 mA, the LED will turn off.

http://web.quick.cz/PetrLBC/zajic.htm

I lost my native charger from a digital camera on a business trip. Buy a new type of "frog". The toad crushed, because I am a radio amateur and therefore I can solder the charging of lithium batteries myself with my own hands, and besides, it is very easy to do. The charger of absolutely any lithium battery is a 5-volt constant voltage source, which gives a charge current equal to 0.5-1.0 of the battery capacity. For example, if the battery capacity 1000 mAh, the charger must give a current of at least 500 mA.

Do not believe, so try, and we will help.

The charge process is shown in the graph. At the initial moment, the charging current is constant, when the voltage level Umax on the battery is reached, the charger switches to the mode when the voltage is constant, and the current asymptotically tends to zero.

Lithium Battery Charge Process Chart

The output voltage of lithium batteries is usually 4.2V, and the nominal voltage is about 3.7V. It is not recommended to charge these batteries to a full 4.2V, as this reduces their battery life. If you reduce the output voltage to 4.1V, the capacitance will drop by almost 10%, but at the same time, the number of charge-discharge cycles will almost double. When using these batteries, it is extremely undesirable to bring the rated voltage below the level of 3.4 ... 3.3V.

Lithium battery charging circuit on LM317

As you can see the scheme is quite simple. Built on stabilizers LM317 and TL431. Another of the radio components there are a couple of diodes, resistances and capacitors. The device almost does not require adjustment, with enough tuning resistance R8 we set the voltage at the device output at a nominal value of 4.2 volts without a connected battery. Resistances R4 and R6 set the charging current. To indicate the operation of the structure, the “charge” LED is designed, which, when an empty battery is connected, lights up, and it goes out as it charges.

We proceed to the assembly of the structure for charging lithium batteries. We find a suitable housing in it, you can place a simple transformer power supply for five volts, and the above scheme is considered.

To connect a rechargeable battery, I cut out two brass strips and installed them on the sockets. The nut adjusts the distance between the contacts that are connected to the rechargeable battery.

Did, something like clothespins. You can also set the switch to change the polarity on the sockets of the charger - in some cases this can greatly help. I propose to make a printed circuit board according to the LUT method, we take away the Sprint Layout drawing from the link above.

With a huge mass of positive characteristics, lithium batteries have significant disadvantages, such as high sensitivity to excess charge voltage, which can lead to heating and intense gas generation. And since the battery has a sealed design, excessive gas evolution should lead to bloating or explosion. In addition, lithium batteries cannot tolerate overcharging.

Thanks to the use of specialized microcircuits in branded chargers that control voltage, this problem is not familiar to many users, but this does not mean that it does not exist. Therefore, to charge lithium batteries, we need just such a device, and the circuit discussed above is only its prototype.

Charging lithium batteries universal circuit

The device allows you to charge lithium batteries with a voltage of 3.6V or 3.7V. At the first stage, the charge is carried out with a stable current of 245mA or 490mA (set manually), when the voltage on the batteries increases to the level of 4.1V or 4.2V, the charge continues while maintaining a stable voltage and decreasing value of the charging current as soon as the last drops to the threshold value (set manually from 20mA to 350mA) the battery automatically stops.

The LM317 stabilizer maintains the voltage at the resistance R9 at about 1.25V, thereby maintaining a stable value of the current flowing through it, and therefore through a rechargeable battery. The output voltage is limited by the stabilizer TL431, connected to the control input LM317. The value of the limiting voltage is selected using a divider on the resistances R12 ... R14. Resistance R11 limits the supply current of the TL431.

On the operational amplifier DA2.2 LM358, resistances R5 ... R8 and bipolar transistor VT2, a current-voltage converter is built. The voltage at its output is proportional to the current flowing through the resistance R9 and is calculated by the formula:

For values \u200b\u200bin the diagram, the coefficient of conversion of current to voltage is 10, i.e. at a current through resistance R9 of 245mA, the voltage at R5 is 2.45V.

With R5, the voltage goes to the non-inverting input of the op amp DA2.1. The voltage from the adjustable divider at the resistances R2 ... R4 is supplied to the inverting input of the comparator. The power supply voltage of the divider is stabilized by LM78L05. The switching threshold of the comparator is set by the value of the variable resistance R3.

Charging lithium batteries circuit setting.Instead of the toggle switch SB1, put a jumper and supply voltage to the circuit, select the resistance R12 ... R14 to make the output voltage 4.1V and 4.2V for the open and closed state of the switch SA2.

The SA1 toggle switch sets the value of the charge current (245mA or 490mA). We select the maximum voltage value with the SA2 toggle switch, select 4.1V for 3.6V batteries, and 4.2V for 3.7V batteries. With the variable resistance engine R3 we set the current value at which the battery charge should end (approximately 0.07 ... 0.1C), connect the battery and press the SB1 toggle switch. The lithium battery charge process should start and the indicator on the VD2 LED lights up. When the charge current decreases below the threshold, the high level at the output DA2.1 will change to low, the field effect transistor VT1 closes and the relay coil K1 is disconnected, breaking the battery from the charger with its front contact K1.

I bring a drawing of the circuit board of the charger and recommend making it yourself do-it-yourself

A universal adapter was made to charge lithium batteries from mobile phones and smartphones:

All batteries of this type must be used in accordance with certain recommendations. These rules can be conditionally divided into two groups: Independent and user-dependent.

The first group includes the fundamental rules for charging and discharging batteries, which are controlled by a special controller for the charger:

The lithium battery must be in a state where its voltage should not exceed 4.2 volts and not fall below 2.7 volts. These limits are the maximum and minimum charge levels. The minimum level of 2.7 volts is relevant for batteries with coke electrodes, but modern lithium batteries are made with graphite electrodes. For them, the minimum limit is 3 volts.

The amount of energy given by the battery when the charge changes from 100% to 0% is battery capacity. A number of manufacturers limit the maximum voltage to 4.1 volts, while the lithium battery will last much longer, but it will lose about 10% in capacity. Sometimes the lower limit rises to 3.0 and even 3.3 volts, but also with a decrease in the level of capacity.

The longest battery life is at 45% charge, and with an increase or decrease the life time is reduced. If the charge is in the above range, the change in life is not significant.

If the voltage on the battery goes beyond the limits indicated above, even for a short time, its useful life drops sharply.

The battery charger controllers of the chargers never allow the voltage on the battery to rise above 4.2 volts during charging, but can limit the minimum level during discharge in different ways.

The second group of user-specific rules includes the following rules:

Try not to discharge the battery to the minimum charge level and, especially, to the state when the device itself turns off, well, and if this happens, it is advisable to charge the battery as quickly as possible.

Do not be afraid of frequent recharges, including incomplete lithium battery, this is absolutely no matter.

Battery capacity is temperature dependent. So, at a 100% charge level at room temperature, when going out in the cold, the battery charge will drop to 80%, which is basically neither dangerous nor critical. But it can be vice versa if you put a 100% charged battery on the battery, its charge level will increase to 110%, which is very dangerous for him and can drastically shorten his life.

An ideal condition for long-term storage of the battery is to be outside the device with a charge of about 50%

If after purchasing a battery with increased capacity after a few days of use. A device with a battery starts to glitch and the battery charging hangs or turns off, most likely your charger, which worked fine on an old battery, is simply not able to provide the required charging current for a large capacity.

A selection of original phone chargers consisting only of simple and interesting amateur radio ideas and developments

This amateur design is designed to charge lithium batteries from mobile phones and type 18650, and most importantly ensures the correct charging of the battery. The device has an LED charge indicator. Red indicates that the battery is charging, green indicates that the battery is fully charged. Smart charging is obtained thanks to the use of a specialized charge controller on the BQ2057CSN chip.

In modern lithium batteries, pure lithium is not used. Therefore, three main varieties of lithium batteries were distributed: Lithium-ion (Li-ion) Unom. - 3.6V; Lithium polymer (Li-Po, Li-polymer or "lipo"). Unom. - 3.7V; Lithium iron phosphate (Li-Fe or LFP). Unom - 3.3V.

disadvantagesThe main disadvantage of Li-ion batteries, I would single them out fire hazard due to overvoltage or overheating. But, lithium-iron-phosphate batteries do not have such a fatty minus - they are completely fireproof.

Lithium batteries are very h insensitive to cold and quickly lose their capacity and stop charging.

Requires a charge controller

At deep discharge lithium batteries lose their initial properties.

If the battery does not "work" for a long time, then first the voltage on it will drop to a threshold level, and then a deep discharge will begin as soon as the voltage drops to 2.5V, this will lead to its failure. Therefore, from time to time we recharge the batteries of laptops, cell phones, mp3 players.