Peltier thermoelectric cooler.

The principle of operation was borrowed from net: The basis of the Peltier elements is the contact of two conductive materials with different levels of electron energy in the conduction band. When current flows through the contact of such materials, the electron must acquire energy in order to transfer to a higher-energy conduction band of another semiconductor. When this energy is absorbed, the contact point of the semiconductors is cooled. When the current flows in the opposite direction, the contact point of the semiconductors is heated, in addition to the usual thermal effect.

When metals come into contact, the Peltier effect is so small that it is invisible against the background of ohmic heating and heat conduction phenomena. Therefore, in practical use, the contact of two semiconductors is used.

Appearance of the Peltier element. When a current is passed, heat is transferred from one side to the other. A Peltier element consists of one or more pairs of small semiconductor parallelepipeds - one n-type and one p-type in a pair (usually bismuth telluride, Bi2Te3 and silicon germanium), which are paired using metal jumpers. Metal bridges simultaneously serve as thermal contacts and are insulated with a non-conductive film or ceramic plate. The pairs of parallelepipeds are connected in such a way that a series connection of many pairs of semiconductors with different types of conductivity is formed, so that at the top there are one sequence of compounds (n-\u003e p), and the bottom are opposite (p-\u003e n). Electric current flows sequentially through all parallelepipeds. Depending on the direction of the current, the upper contacts are cooled, and the lower ones are heated - or vice versa. Thus, an electric current transfers heat from one side of the Peltier element to the opposite and creates a temperature difference.

If you cool the heating side of a Peltier element, for example with a radiator and a fan, then the temperature of the cold side becomes even lower. In single-stage elements, depending on the type of element and the magnitude of the current, the temperature difference can reach approximately 70 K /

Description

The Peltier element is a thermoelectric converter, which, when voltage is applied, is able to create a temperature difference on the plates, that is, to pump heat or cold. The presented Peltier element is used for cooling computer boards (subject to efficient heat removal), for cooling or heating water. Peltier elements are also used in portable and automobile refrigerators.

Peltier cell powered by 12 volts.

For heating, you just need to change the polarity.

Peltier plate dimensions: 40 x 40 x 4 millimeters.

Operating temperature range: from -30 to +70? ..

Operating voltage: 9-15 volts.

Power Consumption: 0.5-6 A.

Maximum power consumption: 60 watts.

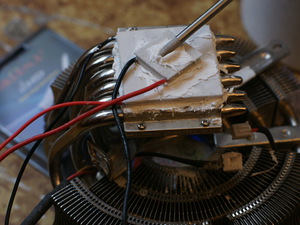

A funny little thing, we connect 12v + - it cools; we change the polarity; it warms up. It is used in many car refrigerators, in any case I have one. You can attach a compact scheme to the glove compartment so that chocolate would not melt in the summer! For use and effective use, you need to use a cooling radiator - as a test I used a radiator from a computer processor, it is possible with a cooler. The better the cooling, the Peltier effect is stronger and more efficient. When connected to a car battery at 12v, the consumption current was 5 amperes. In a word, the element is gluttonous. Since I have not yet assembled the entire circuit, but conducted only trial tests, without instrumental temperature measurements. So, with a cooling mode, a slight frost appeared within 10 minutes. In the heating mode, the water in a metal cup boiled. The efficiency of this cooler, of course, is low, but the price of the device and the ability to experiment make the purchase justified. The rest is in the photo

Peltier elements - it would seem, is no longer news, but many do not fully understand the principle of their work, and do not know what can be made from modules and why they are needed. Inventor Igor Beletsky will show some visual experiments so that you have an understanding of what these records are capable of.

They are easy to purchase on the Internet and order delivery by mail. It is best to buy Peltier at this Chinese store. There is also a special cooling cooler.

Peltier module (element)

The most popular among practitioners keen on ideas of free natural energy and manufacturers of technical devices is an element with a size of 40 by 40 millimeters with a marking. This means that it consists of 127 pairs of tiny thermocouples - semiconductors of various types, which are paired with copper jumpers in a series circuit and are designed for direct current up to 5 A at a voltage of 12 volts.

Some people think that Peltier modules are something like solar panels - because they are the same flat, stick out wiring, and both of them can generate electric current. Alas, this is not entirely true. To understand how the mysterious records function, watch the video of I. Beletsky, a description in text format below.

Pelt and Zebek effects - module functions

This device has as many as two operating modes - 1. the generation of cold and heat; 2 - electric current generation.

1. So famous peltier effect (warm and cold). This is when you bring a constant current to the element and notice that one of its sides has become warmer and the other colder. Thus, it works like a heat pump. Very useful property. No doubt about it.

2. But it turned out that the reverse process takes place - the so-called zebek effect, namely, the occurrence of an electric current when establishing and maintaining a certain temperature difference on the sides of the module itself (plate).

Note. Never overheat elements if you want to continue experimenting with them. The semiconductors in the module are soldered by solder, the melting temperature of which can lie in the range from eighty to two hundred degrees. And considering where most of these elements are manufactured today, one can only guess on what nozzles they were soldered.

Scheme. How electricity is generated by heating the Peltier sides

The whole trouble is that this element will work normally only with effective cooling.

Electricity test

For example, we want to test the Zebek effect. Put a mug of boiling water on top. Thus, 100 degrees allowed for heating are not exceeded.

We observe the appearance of tension. Interestingly, if you change the direction of the heat flux through the module, then the direction of the direct current will change. But over time, on the second side, due to the thermal conductivity of the Peltier element, the temperature will also rise and the voltage will naturally drop.

For the effect to be permanent, constant heat removal is needed. For this, the module is placed on a massive radiator and preferably with active cooling. The indicators are clearly better, as you understand. This requires additional energy.

Let's say you want to make camp charging for mobile phones out of this element. Then, in nature, the radiator can be placed in cold water, possibly even flowing or icy, which is undoubtedly even better. The use of these modules in the winter with a good free minus is the most promising.

True, one element for charging the phone will obviously not be enough. But two is better. Naturally, if you increase the heating, then the output power will also increase. But this is a very risky step that can only be done for the sake of experiment. The operation of such a generator will not last long.

Now we turn to the Peltier effect, that is, to the production of cold.

Pelt Modules Refrigerator - How Effective Is It?

For the experiment, a car refrigerator will be used. Useful volume of its 20 liters. Please note - the declared power is 48 watts at a current of 4 amperes and a constant voltage of 12 volts. This means that inside there is only 1 small Peltier element. For those who are not on the topic, let’s reveal a secret - an ordinary home refrigerator, the size of which is many times larger, has the same power. Well, okay, now is not about that. Check its effectiveness. For example, we set it the minimum task to cool a glass of water with a room temperature of 26 degrees. For the operation of the refrigerator, we will use a power supply that is ideally suited for its parameters. Additionally, a wattmeter will be placed in the circuit. It will display current, voltage and power in real time. But the most important thing is consumption, the so-called watt per hour. Thus, we can approximately estimate the energy consumption of our refrigerator.

Turn on and see, everything works great. Here is a current of 4.29 A. The voltage is 11.15 Volts. Power 47.9 watts. 0.1 Watt-hours.

While the process is going on, we will conduct a more visual experiment that will show what exactly happens in the refrigerator. When we apply a constant current to the element, it will begin to pump heat from one side to the other.

By the way, if you change the direction of the current, the direction of heat transfer will also change, which is very convenient. The main thing is not to forget about active cooling, because fifty watts of electrical power heats the element instantly. The more efficiently we remove heat from the hot side, the colder the other.

As you can see, on the very surface of the module, water freezes very quickly, well, it would be so much energy.

But back to our refrigerator. After one hour of operation, the air temperature inside dropped to fifteen degrees, and at the water dropped to 20. It was surprising that in an hour of operation he ate clearly 48 watts. Two hours later, the air had 13 degrees, and the water had 17. Finally, after three hours of operation, the air temperature stopped at 13 degrees, and in a glass of water it was 15 and below 12 it will not drop. Well, so-so refrigerator, given that it was not full of drinks. But at the same time, this monster consumed 140 watts. For a home network, it may not be much, but for a car battery this is already quite noticeable. Therefore, there is only one element. Because no more battery just pulls. And this means that the efficiency of such a module is negligible - literally a few percent, which again depends on the manufacturer. Such a refrigerator is more like a good thermos. If they had taken cold food from home, then he would simply not have allowed them to heat up quickly. Making such refrigerators large is energetically disadvantageous.

When is Peltier effective?

By the way, this also applies to home-made people trying to make automobile air conditioners on this principle. There are more efficient technologies, but using Peltier elements to cool something small and compact is just the perfect solution. There is a whole range of such devices, for example, cooling processors or microcircuits of various small-sized devices. This is most likely the most important plus of such elements. They are miniature and minimal in weight. Compared with the same photocells, Peltier certainly has more minuses, but the effect itself certainly deserves attention. In the end, it all depends on the tasks being solved, and if the energy is free, then a high efficiency is not so important.

How many degrees can an element be cooled? About it .

Conclusion

Peltier modules, popular among radio amateurs and engineers, are electronic elements that are actively used for cooling and generating electricity. On their basis, power sources are developed for lighting or charging devices in camp conditions, mobile compact refrigerators for cars. There are attempts to use for cooling computer processors. The operation of the devices is based on 2 mechanisms: when one side of the Peltier plate is heated and the second is cooled, an electric current is generated; when electricity is supplied to the contacts, one side of the plate is cooled, the other is heated.

Standard thermoelectric modules have a reciprocal principle of operation. In this article we will talk about the use of Peltier-Seebeck modules in heat exchangers and give an example of the assembly of a water cooler and a basic cooling system for air with the possibility of a reverse start (heating).

The principle of operation of thermoelectric modules (TEM) used for cooling is based on the Seebeck effect - the inverse process relative to the Peltier effect. The main element is the same TEM described in the first part. When applying direct current to the field of thermocouples, a temperature difference is observed on the planes of the ceramic plate. This is a fact based on a thermodynamic process that we will not describe (so as not to bore scientific calculations), but we will show how to apply it in everyday life.

Note. To build the units, the instructions for which are given below, you will need basic practical skills in assembling electrical circuits. The given node models are approximate and can be replaced by similar (or more / less powerful) at the discretion of the wizard.

How to make a cooler for water cooling yourself

The pessimistic reader already understood that the “miracle ladle” from the first part can be used to cool the liquid if you run it “in the opposite direction” by connecting a direct current.

TEMs are used in each water cooler. It is quite possible to build an analog of this factory device with your own hands, while it will work no worse. We will describe the principle of operation and the assembly scheme. The layout and options for execution can be selected based on their own needs. For example, make it portable or stationary, integrated into kitchen furniture or a drinking water treatment system. The latter option is optimal, since the cooling in the system will be controllable (upon the fact of power supply).

For this we need:

- Rectangular flat sealed stainless steel container with dimensions 100x100x30 (heat exchanger flask) with ½ inch threaded outlets on short sides. This is the only element the manufacture of which is best ordered by the master at the factory.

- A supply of drinking water with a ½ inch fitting (from a tank or water supply).

- Power supply for 10-12 volts with adjustable current.

- Thermoelectric modules TEC1-12705 (40x40) - 2 pcs.

- Wire cross section 0.2 mm.

- Hot melt adhesive or thermal paste.

- Key for 2 channels (toggle switch, button).

- Faucet, soldering iron, solder.

Using hot-melt adhesive, fix the TEM to the flask. We connect the wires in the appropriate groups (plus and minus). We determine the convenient location of the key, given the possibility of replacement during repair and availability during use. We include it in the circuit. We connect the wires to the power supply. We test the circuit.

Attention! When testing, limit yourself to observing the fact of proper operation, but do not try to give the maximum load dry - this can lead to failure of the TEM (cannot be repaired).

Then we connect the inlet fitting of the flask-heat exchanger with the water supply channel, and the outlet - with the inlet (flexible or rigid) to the tap.

We fill the system with water and set the optimal amperage at the desired jet pressure. Optimum pressure - a little stronger than gravity. For the abstraction of cool drinking water this will be enough. The remaining nuances - fasteners, wire lengths, location - are purely individual in each individual case.

This basic system can be developed and improved. For example, installing a thermostat in a heat exchanger and connecting it to a circuit instead of a key (toggle switch) is suitable where water of a certain temperature is constantly needed. The heat exchanger flask can be made of silver for additional ionization of water. By incorporating an EK-1674 step-up DC-DC converter in the system, you can reduce energy consumption to a minimum.

Calculation of costs for building a cooler:

The fin radiator is not involved in this system, because the goal - cooling (but not freezing) a small volume of water (300 ml) - is achieved without it.

How to make a mini-fridge, chiller or air conditioner on thermoelectric modules on your own

A more difficult task is air cooling. If in the case of water the efficiency of the cooler is guaranteed by the difference in the density of the media (water - air), then in the case of a homogeneous medium (air - air) the situation is more complicated. The main difficulty is the removal of temperature from the hot side of the TEM surface. More precisely - synchronous temperature removal from both surfaces. If you simply start the Peltier-Seebeck element, the heated and cooled air will mix and the temperature will equalize.

In confined spaces of small volume (up to 0.7 m 3), a cooling system based on TEM with two-sided air outlet is quite applicable. This allows you to build a new cooling box or give a second life to the old refrigerator (freezer). To do this, you will have to complicate the system a little by including a pair of exhaust fans of mutual power, a temperature switch, a fin radiator, and use more efficient thermoelectric modules.

We need (for one base cooling point):

- TEM TES1-12712 (40X40), 106 watts - 1 pc.

- RQA 12025HSL 110VAC fan (or more powerful) - 2 pcs.

- Radiator HS 036-100 (100x85x25 mm).

- Thermostat TAM-133-1m (temperature switch with sensor).

- DC power supply 12 volts, 6 amperes (adjustable).

- Duralumin sheet.

- Wires, thermal grease, fasteners

In the finished box, in the upper part of the cooled zone, we make a rectangular window with dimensions of 100x100 mm. We cut out two duralumin plates with dimensions of 130x130 mm and 180x180 mm. We fix the fan in the center of the smaller plate in such a way that a 1 cm air flow remains. We install a temperature relay inside the box. We mount the smaller of the plates from the inside of the box (with a fan inside the box) onto screws or rivets through sealant. We stick TEMs on the mounted plate and output the wires. We cut out and bend a large plate so that it enters the mounting hole, but at the same time there are sides for fixing to the box wall from the outside. We fix a radiator and a second fan on it. We generously lubricate the thermal grease TEMs and mount the plate to the box wall through the sealant.

Attention! There must be a maximum contact between the TEM area and the plate!

We assemble an electric circuit. We recommend turning on the fans at constant maximum power, and the current for TEM - through the regulator. This will provide an effective temperature rise and air mixing during operation in different modes (not at full power).

The advantages of this design:

- silent operation in comparison with compressor refrigerators;

- lack of mechanisms and moving parts, friction forces (nothing to break);

- liquid heat carriers (freon) are not used;

- total power consumption of about 200 watts;

- you can upgrade the design, vary the performance;

- the availability and maintainability of individual units.

Disadvantages:

- condensation may appear on duralumin plates;

- outdoor control unit;

- many factors and nuances of work are identified empirically when used;

- small scope.

Calculation of the cost of building the base cooling system of the refrigerator and air conditioning:

| Name | Units rev. | Qty | Unit price / rub. | Article rub. |

| TEM TES1-12712 (40X40), 106 watts | pC. | 1 | 600 | 600 |

| RQA Fan 12025HSL 110VAC | pC. | 2 | 150 | 300 |

| Duralumin 3 mm | pC. | 1 | 300 | 300 |

| DC power supply | pC. | 1 | 300 | 300 |

| Thermostat TAM-133-1m | pC. | 1 | 250 | 250 |

| Radiator HS 036-100 | pC. | 1 | 220 | 220 |

| Wires, thermal grease, fasteners, solder | - | - | 300 | 300 |

| Total | 2270 |

In principle, this design is a ready-to-use built-in air conditioner, which can be installed in the cab of a car, tractor, in a closed aviary or security booth. It is only necessary to consider constructive protection against atmospheric precipitation.

The power reserve of the TEC1-12712 module is quite large. The temperature amplitude on the sides of the element can reach 50 degrees. At a room temperature of +27 ° C and the use of a liquid cooling system (radiator + fan), you can extract impressive minus 25 ° C at the output! This allows you to create uncompressed and quiet freezers, even at home.

Where else are thermoelectric modules used?

The Peltier-Seebeck effect has been known since the 1840s. It is actively used to this day, thanks to the stability of the laws of physics. There will always be a place for a thermoelectric module where there is excess energy or if heat transfer must be completed quickly and silently.

The main applications of thermoelectric modules:

- Chip cooling. Fans, as the main heat exchanger, are a thing of the past. They are replaced by compact, silent and almost eternal TEMs.

- Engineering. Even the most advanced ICE emits exhaust gases from the combustion chamber. Engineers use their heat to obtain additional energy using Peltier elements. The collected energy is fed back to the engine systems, but in the form of direct current, which saves fuel.

- Appliances. All that is described above plus most household appliances that work on cooling or heating (except for compressor refrigerators).

And a little secret in the end. Our module has an almost wonderful property - reversibility. This means that when changing the polarity of the direct current on the module wires (using the switch), the hot and cold surfaces change places. The cooler turns into a heater, a refrigerator into a heat chamber (incubator), and the air conditioner turns into a low-power fan heater. You do not have to change the device layout for this. Just change the polarity.

This principle is used in a device called a recuperator. It is a box consisting of two isolated chambers that communicate with each other using fans. Using Peltier modules, cold air from the street is heated by energy extracted from the heated air that is removed from the room. The device allows you to save on heating the house.

Vitaly Dolbinov, rmnt.ru

The thermoconverter (Peltier module) works according to the principle opposite to the action of a thermocouple - the appearance of a temperature difference when an electric current flows.

How does the Peltier element work?

It is quite simple to use the Peltier module, the principle of which is the generation or absorption of heat at the moment of contact of different materials during the passage through it of the energy flux of electrons before and after the contact is different. If the output is less, it means that heat is released there. When the electrons in the contact are inhibited by the electric field, they transfer kinetic energy to the crystal lattice, heating it. If they accelerate, heat is absorbed. This is due to the fact that part of the energy is taken from the crystal lattice and its cooling occurs.

To a large extent, this phenomenon is inherent in semiconductors, due to the large difference in charges.

The Peltier module, the use of which is the subject of our review, is used to create thermoelectric cooling devices (TEM). The simplest of them consists of two p- and n-type semiconductors connected in series through copper contacts.

If the electrons move from the semiconductor "p" to "n", at the first transition with a metal jumper, they recombine with the release of energy. The next transition from the semiconductor "p" to the copper conductor is accompanied by the "pulling" of electrons through the contact by an electric field. This process leads to energy absorption and cooling of the area around the contact. Similarly, processes occur at the following transitions.

When the heated and cooled contacts are located in different parallel planes, a practical implementation of the method is obtained. Semiconductors are made from selenium, bismuth, antimony or tellurium. The Peltier module accommodates a large number of thermocouples placed between ceramic plates made of nitride or aluminum oxide.

Factors Affecting TEM Efficiency

- Current strength.

- The number of thermocouples (up to several hundred).

- Types of semiconductors.

- Cooling rate.

It has not yet been possible to achieve large values \u200b\u200bdue to low efficiency (5-8%) and high cost. In order for TEM to work successfully, it is necessary to ensure efficient heat removal from the heated side. This creates difficulties in the practical implementation of the method. If you change the polarity, the cold and hot sides change with each other.

Advantages and disadvantages of modules

The need for TEM appeared with the advent of electronic devices that needed miniature cooling systems. The advantages of the modules are as follows:

- compactness;

- lack of movable joints;

- peltier module operating principle is reversible when changing polarity;

- simplicity of cascade connections to increase power.

The main disadvantage of the module is its low efficiency. This is manifested in high power consumption while achieving the desired cooling effect. In addition, it has a high cost.

TEM application

Peltier module is mainly used for cooling microcircuits and small parts. The beginning was laid for cooling elements of military equipment:

- microcircuits;

- infrared detectors;

- laser elements;

- crystal oscillators.

The Peltier thermoelectric module gradually began to be used in household appliances: to create refrigerators, air conditioners, generators, temperature regulators. Its main purpose is to cool small objects.

CPU cooling

The main components of computers are constantly being improved, which leads to an increase in heat dissipation. Together with them, cooling systems are developed using innovative technologies, with modern controls. The Peltier module found application in this area primarily in the cooling of microcircuits and other radio components. Traditional coolers can no longer cope with forced overclocking modes of microprocessors. And an increase in the frequency of the processors makes it possible to increase their speed.

Increasing the fan speed results in significant noise. It is eliminated through the use of a Peltier module in a combined cooling system. In this way, leading firms quickly mastered the production of efficient cooling systems, which were in great demand.

Heat is usually removed from processors by coolers. Airflow can be drawn in from the outside or from inside the system unit. The main problem is that the air temperature is sometimes insufficient for heat removal. Therefore, TEMs began to be used to cool the air flow entering the system unit, thereby increasing the heat transfer efficiency. Thus, the built-in air conditioning is an assistant to the traditional computer cooling system.

Aluminum radiators are mounted on both sides of the module. From the cold plate side, cooling air is pumped to the processor. After he takes the heat, another fan blows it through the radiator of the module’s hot plate.

A modern TEM is controlled by an electronic device with a temperature sensor, where the degree of cooling is proportional to the heating of the processor.

Enhancing the cooling of processors also poses some problems.

- The simple Peltier cooling modules are designed for continuous operation. With reduced power consumption, heat dissipation is also reduced, which can cause crystal overcooling and subsequent processor freezing.

- If the operation of the cooler and the refrigerator is not properly coordinated, the latter can go into heating mode instead of cooling. A source of additional heat will cause the processor to overheat.

Thus, modern processors need advanced cooling technologies with control over the operation of the modules themselves. Such changes in operating modes do not occur with video cards, which also require intensive cooling. Therefore, TEM is ideal for them.

DIY refrigerator

In the middle of the last century, domestic industry tried to master the production of small-sized refrigerators based on the Peltier effect. Existing technologies of that time did not allow this. Now the constraining factor is mainly the high price, but attempts continue, and successes have already been achieved.

The widespread production of thermoelectric devices allows you to create your own small refrigerator, convenient for use in cars. Its basis is a "sandwich", which is done as follows.

- A layer of heat-conducting paste of the type KPT-8 is applied to the upper radiator and the Peltier module is glued on one side of the ceramic surface.

- Similarly, another radiator is attached to it from the bottom side, designed to be placed in the refrigerator chamber.

- The whole device is tightly compressed and dried for 4-5 hours.

- Coolers are installed on both radiators: the upper one will remove heat, and the lower one will equalize the temperature in the refrigerator chamber.

The refrigerator case is made with a heat-insulating gasket inside. It is important that it closes tightly. To do this, you can use a regular plastic tool box.

12 V power is supplied from the vehicle system. It can also be made from 220 V AC, with a power supply. The AC to DC conversion circuit is the simplest. It contains a rectifier bridge and a ripple-smoothing capacitor. It is important that they do not exceed 5% of the nominal value at the output, otherwise the efficiency of the device decreases. The module has two outputs from colored wires. A plus is always connected to red, a minus to black.

TEM power should correspond to the volume of the box. The first 3 digits of the marking indicate the number of pairs of semiconductor trace elements inside the module (49-127 or more). expressed by the last two digits of the marking (from 3 to 15 A). If there is not enough power, one more module must be glued to the radiators.

Note! If the current strength exceeds the power of the element, it will heat up on both sides and will quickly fail.

Peltier module: electric power generator

TEM can be used to generate electricity. To do this, create a temperature difference between the plates, and the thermocouples located between them will generate an electric current.

For practical use, a TEM of at least 5 V. is needed. Then it can be used to charge a mobile phone with it. Due to the low efficiency of the Peltier module, a step-up DC-DC converter is required. To build the generator you will need:

- 2 Peltier modules TEC1-12705 with a plate size of 40x40 mm;

- converter EK-1674;

- 3 mm thick aluminum plates;

- pan for water;

- heat resistant adhesive.

Between the plates, two modules are placed on the glue, and then the whole structure is fixed at the bottom of the pan. If you fill it with water and put it on fire, you get the required temperature difference that generates an EMF of about 1.5 V. By connecting the modules to a boost converter, you can increase the voltage to 5 V, which is necessary to charge the phone’s battery.

The greater the temperature difference between water and the bottom heated plate, the more efficient the generator is. Therefore, we must try to reduce the heating of water in different ways: make it flowing, often replace it with fresh, etc. An effective way to increase the temperature difference is to cascade the inclusion of modules when they are stacked on top of each other. The increase in the overall dimensions of the device allows you to place more elements between the plates and thereby increase the overall power.

Generator performance will be enough to charge small batteries, LED lamps or a radio. Note! To create thermal generators, modules are required that can operate at 300-400 0 C! The rest is only suitable for trial testing.

Unlike other alternative means of generating electricity, they can work while driving, if you create something like a catalytic heater.

Domestic Peltier Modules

TEM of its production appeared on our market not so long ago. They are highly reliable and have good characteristics. The Peltier module, which is in great demand, has dimensions of 40x40 mm. It is designed for a maximum current of 6 A and a voltage of up to 15 V.

You can buy a domestic Peltier module for a small price. At 85 W, it creates a temperature difference of 60 0 C. Together with the cooler, it is able to protect a processor with a dissipated power of 40 W from overheating.

Characteristics of modules of leading companies

Foreign devices are on the market in a greater variety. To protect the processors of leading companies, a Peltier module is used as a refrigerator PAX56B, the price of which, complete with a fan, is $ 35.

With dimensions of 30x30 mm, it maintains the temperature of the processor no higher than 63 0 C with an allocated power of 25 watts. A voltage of 5 V is sufficient for power, and the current does not exceed 1.5 A.

The P6tier RA6EXH module, which provides normal temperature conditions with a dissipation power of 40 watts, is well suited for cooling the processor. The area of \u200b\u200bits module is 40x40 mm, and the current consumption is up to 8 A. In addition to its impressive dimensions - 60x60x52.5 mm (together with a fan) - the device requires free space around it. Its price is $ 65.

When a Peltier module is used, its technical characteristics must correspond to the needs of the refrigerated devices. They should not have too low a temperature. This can lead to moisture condensation, which is detrimental to the electronics.

Modules for the manufacture of generators, such as differ in greater power - 72 W and 108 W, respectively. They are distinguished by marking, always applied on the hot side. The maximum permissible temperature of the hot side is 150-160 0 C. The greater the temperature difference between the plates, the higher the output voltage. The device operates at a maximum temperature difference of 600 0 C.

You can buy a Peltier module inexpensively - about $ 10 or less apiece, if you search well. Quite often, sellers significantly inflate prices, but can be found several times cheaper if purchased on sale.

Conclusion

The Peltier effect is currently used in the creation of small refrigerators, which are necessary for modern technology. The reversibility of the process makes it possible to manufacture microelectric power plants that are in demand for charging batteries of electronic devices.

Unlike other means of alternative generation of electricity, they can work while driving, if you install a catalytic heater.

Many have heard about the "magic" Peltier elements - with the passage of current through them, one side cools and the other heats up. This works in the opposite direction - if one side is heated and the other is cooled, electricity is generated. The Peltier effect has been known since 1834, but to this day we are not ceased to be pleased with innovative products based on it (you just need to remember that when generating electricity, like solar panels, there is a point of maximum power, and if you work far from it - efficiency generation is greatly reduced).

Recently, the Chinese have pushed, and flooded the Internet with their relatively cheap modules, so experimenting with them no longer takes too much money. The Chinese promise a maximum temperature difference between hot and cold side of 60-67 degrees. Hmmm ... But what if we take 5 elements, connect in series, then we should get 20C-67 * 5 \u003d -315 degrees! But something tells me that everything is not so simple ...

Brief theory

The classic "Chinese" Peltier elements are 127 elements connected in series and soldered to a ceramic "printed circuit board" made of Al2O3. Accordingly, if the operating voltage is 12V, then each element accounts for only 94mV. There are elements with a different number of consecutive elements, and accordingly with a different voltage (for example 5V).It must be remembered that the Peltier element is not a resistor, its resistance is non-linear, so if we apply 12V, we may not be able to get 6 amperes (for a 6 ampere element) - the current may change depending on the temperature (but not too much ) Also, at 5V (i.e. less than the nominal value), the current will not be 2.5A, but less.

In addition, the amount of heat transferred is highly dependent on the temperature difference between the surfaces. With a difference of 60-67С - heat transfer tends to 0, and with a zero difference - 51 watts for a 12 * 6 \u003d 72-watt cell. Obviously, this already does not allow connecting the elements in a series so simply - it is necessary that each next one be smaller in size than the previous one, otherwise the coldest element will try to give more heat (72W) than the element of the next stage can pass through itself at the desired temperature difference (1 -51W).

Peltier elements are assembled with fusible solder with a melting point of 138C - so if an element accidentally remains without cooling and overheats, it will be enough to solder one of 127 * 2 contacts to throw the element into a landfill. Well, the elements are very fragile - both the ceramics and the cooling elements themselves - I accidentally tore up 2 elements “along” due to the thermally paste that had dried up tightly:

Try

So, the small element is 5V * 2A, the large is 12 * 9A. Heatpipe cooler, room temperature. Result: -19 degrees. Strange ... 20-67-67 \u003d -114, but it turned out miserable -19 ...

The idea is to take everything out into the freezing air, but there is a problem - a cooler on heat pipes cools well only if the temperature of the “hot” and “cold” sides of the cooler lies on opposite sides of the gas-liquid phase transition of the tube filler. In our case, this means that the cooler, in principle, is not able to cool anything below + 20C (since only thin walls of heat pipes work below). We'll have to return to the roots - to the all-copper cooling system. And so that the limited performance of the cooler does not affect the measurements, we add a kilogram copper plate - a heat accumulator.

The result is shocking - the same -19 with both one and two stages. Ambient temperature - -10. Those. with zero load, we barely squeezed a miserable 9 degrees difference.

We roll out heavy artillery

It turned out that refrigeration plant # 7 was not far from me, and I decided to drop in with a cardboard box. He returned with 5 kilograms of dry ice (sublimation temperature -78C). We lower the copper construction there - we connect the current - at 12V the temperature instantly starts to rise, at 5V it drops by 1 degree per second, and then it grows rapidly. All hopes are broken ...Conclusions and video for sweets

The effectiveness of conventional Chinese Peltier elements quickly drops at temperatures below zero. And if it is still possible to cool a can of cola with apparent efficiency, then temperatures below -20 cannot be achieved. And the problem is not in specific elements - I tried elements of different models from 3 different sellers - the behavior is the same. It looks like cryogenic stages need elements from other materials (and perhaps each stage needs its own element material).Well, with the remaining dry ice, you can do the following:

PS. And if you mix dry ice with isopropyl alcohol - you get liquid nitrogen for the "poor" - it just as fun freezes and breaks flowers and so on. That's just because alcohol does not boil when in contact with the skin - getting frostbite is much easier.