The Peltier element is a special thermoelectric converter that works according to the Peltier principle of the same name - the occurrence of a temperature difference during the supply of electric current. In English, it is most often referred to as TEC, which means thermoelectric cooler.

How the Peltier Element Works

The operation of the Peltier element is based on the contact of two conductive materials that have different levels of electron energy in the conduction band. When applying electric current through a similar connection, electron gains high energy, then to go into a higher-energy conduction band of another semiconductor. At the moment of absorption of this energy, the cooling point of the conductors is cooled. If the current flows in the opposite direction, then this leads to heating of the contact point and to the usual thermal effect.

If, on the one hand, a good heat dissipation is made, for example, using radiator systems, then the cold side can provide a very low temperature, which will be tens of degrees lower than the temperature of the surrounding world. The magnitude of the current is proportional to the degree of cooling. If you change the polarity of the electric current, then the sides (warm and cold) simply swap places.

In contact with a metal surface, the Peltier element becomes so small that it is almost impossible to notice against the background of ohmic heating and other effects of thermal conductivity. That is why in practice two semiconductors are used.

The number of thermocouples can be the most diverse - from 1 to 100, due to which it is possible to make a Peltier element with almost any indicators of refrigeration capacity.

Practical use

Nowadays, Peltier elements actively used for:

Nowadays, Peltier elements actively used for:

- refrigerators;

- air conditioners;

- car coolers;

- water coolers

- pC graphics cards;

The Peltier element has been widely used in various refrigeration systems, including refrigerators and air conditioners. The ability to reach very low temperatures makes it an excellent solution for cooling electrical appliances or heat-treated technical equipment. Today, developers use Peltier elements in acoustic and sound systems, where they play the role of a conventional cooler. The absence of intense sounds makes the cooling process virtually silent, which is an excellent advantage of the element.

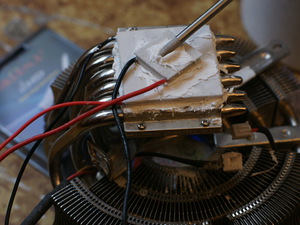

Nowadays, this technology is very popular due to the very powerful heat transfer. In addition, modern Peltier elements are very compact in size, and their radiators are able to store the desired temperature for a long time. Another advantage of Peltier elements is their durability, as they consist of solid fixed elements, which reduces the likelihood of damage. The design of the most common type looks very simple and includes two copper conductors with contacts and connecting wires, as well as an insulating element, which is made of stainless steel or ceramic materials.

Given the simplicity of the design, making a Peltier element with your own hands at home is not difficult. It can be used for refrigerators or other appliances. Before starting work, you need to prepare two metal plates and wiring with contacts. Initially prepare the conductors to be installed at the base of the element. As a rule, conductors with the marking “PP” are used.

Given the simplicity of the design, making a Peltier element with your own hands at home is not difficult. It can be used for refrigerators or other appliances. Before starting work, you need to prepare two metal plates and wiring with contacts. Initially prepare the conductors to be installed at the base of the element. As a rule, conductors with the marking “PP” are used.

It is also worth taking care of the output semiconductors in advance. They will be used to transfer heat to the top plate. Use a soldering iron during installation. At the final stage, you need to connect two wires. The first is installed at the base and firmly fixed near the extreme conductor. It is important to consider that any contact with the plate is eliminated.

The second conductor is attached at the top. It is fixed in the same way as the first - to the extreme conductor. To check the functionality of the device it is worth using a tester. Just connect the two wires to the device and check the voltage. Voltage deviation will be be somewhere around 23 V.

How to make Peltier elements for a refrigerator?

Do-it-yourself Peltier elements for a refrigerator are also made simply and quickly. The first thing to consider before work is the plate material. It must be solid ceramic. As for the conductors, they need to be prepared not less than 20 piecesthat will allow to achieve the maximum temperature difference. With proper calculation, the efficiency can be increased by 70%.

Do-it-yourself Peltier elements for a refrigerator are also made simply and quickly. The first thing to consider before work is the plate material. It must be solid ceramic. As for the conductors, they need to be prepared not less than 20 piecesthat will allow to achieve the maximum temperature difference. With proper calculation, the efficiency can be increased by 70%.

Much depends on the power of the equipment used. If the refrigerator is based on liquid freon, then there will never be problems with power. The Peltier element, which was made by hand, is installed directly near the evaporator, which is installed together with the motor. For such an installation, you will need to stock up on the most standard set of tools and gaskets. They will be applied to the model element from the start relay. With this solution, cooling at the bottom of the device will be much faster.

It is worth remembering that before you make a Peltier element for a refrigerator with your own hands, you need to stock up with a sufficient number of electrical conductors. In order to achieve a difference in temperatures when developing an element with your own hands, use at least 16 wires. Be sure to provide them with high-quality insulation and only then connect to the compressor. After making sure the reliability and safety of the connection between the wires, you can proceed to their connection. After installation is complete, check the voltage limit again with the tester. If the operation of the element was disrupted, this will first of all affect the thermostat. Sometimes a short circuit occurs.

In addition to refrigerators, Peltier elements are also actively used in automobile coolers. Making a quality car refrigerator with your own hands is also quite simple. To do this, you need to find a good ceramic plate with a thickness of at least 1.1 millimeters. Wires must be non-modular. As conductors it is best to use copper wires with bandwidth not less than 4 amperes.

In this regard, the maximum temperature deviation will reach ten degrees, which is considered the norm. In frequent cases, conductors with the marking “PR20” are used, which were able to distinguish themselves by maximum reliability and stability. In addition, they are suitable for various types of contacts. When connecting the device to the capacitor, you should use a soldering iron.

How to make a Peltier element for a drinking water cooler?

A drinking water cooler is a very important and necessary device that cools or heats drinking water on time. To speed up the cooling process, you can apply the Peltier element. You can make it as simple as for a refrigerator or car cooler:

- As a plate it is worth using exclusively a ceramic surface.

- The device uses at least 12 conductors that can withstand high resistance.

- To connect you need to use two wires (preferably copper). The element is installed at the bottom of the cooler. In addition, it may come in contact with the cover of the device. But to prevent possible short circuits, fix all the wiring on the grille or housing.

DIY Peltier element for air conditioners

If we are talking about the Peltier element for air conditioners, then it can only be made from the “PR12” conductor. The fact is that this type of conductors perfectly withstands abnormal temperatures and is capable of delivering up to 23V voltage. The resistance should fluctuate within 3 ohms. Maximum temperature differences will reach 10 degrees and efficiency - 65 percent. Conductors need put in one row.

It is worth noting that the Peltier element can serve as a cooler for the video card of a personal computer. To make the cooler, you need to take 14 conductors, preferably from copper. To connect the Peltier element to the PC video card, you need to use a non-modular conductor. The device itself is mounted next to the built-in cooler on the video card. For fixing, you can use small metal corners, and for fixing ordinary nuts.

If during operation some intense noise and other unnatural sounds are noticed, it is worth checking the wiring performance and inspecting each conductor.

Peltier elements - it would seem, is no longer news, but many do not fully understand the principle of their work, and do not know what can be made from modules and why they are needed. Inventor Igor Beletsky will show some visual experiments so that you have an understanding of what these records are capable of.

They are easy to purchase on the Internet and order delivery by mail. It is best to buy Peltier at this Chinese store. There is also a special cooling cooler.

Peltier module (element)

The most popular among practitioners keen on ideas of free natural energy and manufacturers of technical devices is an element with a size of 40 by 40 millimeters with a marking. This means that it consists of 127 pairs of tiny thermocouples - semiconductors of various types, which are paired with copper jumpers in a series circuit and are designed for direct current up to 5 A at a voltage of 12 volts.

Some people think that Peltier modules are something like solar panels - because they are the same flat, stick out wiring, and both of them can generate electric current. Alas, this is not entirely true. To understand how the mysterious records function, watch the video of I. Beletsky, a description in text format below.

Pelt and Zebek effects - module functions

This device has as many as two operating modes - 1. the generation of cold and heat; 2 - electric current generation.

1. So famous peltier effect (warm and cold). This is when you bring a constant current to the element and notice that one of its sides has become warmer and the other colder. Thus, it works like a heat pump. Very useful property. No doubt about it.

2. But it turned out that the reverse process takes place - the so-called zebek effect, namely, the occurrence of an electric current when establishing and maintaining a certain temperature difference on the sides of the module itself (plate).

Note. Never overheat elements if you want to continue experimenting with them. The semiconductors in the module are soldered by solder, the melting temperature of which can lie in the range from eighty to two hundred degrees. And considering where most of these elements are manufactured today, one can only guess on what nozzles they were soldered.

Scheme. How electricity is generated by heating the Peltier sides

The whole trouble is that this element will work normally only with effective cooling.

Electricity test

For example, we want to test the Zebek effect. Put a mug of boiling water on top. Thus, 100 degrees allowed for heating are not exceeded.

We observe the appearance of tension. Interestingly, if you change the direction of the heat flux through the module, then the direction of the direct current will change. But over time, on the second side, due to the thermal conductivity of the Peltier element, the temperature will also rise and the voltage will naturally drop.

For the effect to be permanent, constant heat removal is needed. For this, the module is placed on a massive radiator and preferably with active cooling. The indicators are clearly better, as you understand. This requires additional energy.

Let's say you want to make camp charging for mobile phones out of this element. Then, in nature, the radiator can be placed in cold water, possibly even flowing or icy, which is undoubtedly even better. The use of these modules in the winter with a good free minus is the most promising.

True, one element for charging the phone will obviously not be enough. But two is better. Naturally, if you increase the heating, then the output power will also increase. But this is a very risky step that can only be done for the sake of experiment. The operation of such a generator will not last long.

Now we turn to the Peltier effect, that is, to the production of cold.

Pelt Modules Refrigerator - How Effective Is It?

For the experiment, a car refrigerator will be used. Useful volume of its 20 liters. Please note - the declared power is 48 watts at a current of 4 amperes and a constant voltage of 12 volts. This means that inside there is only 1 small Peltier element. For those who are not on the topic, let’s reveal a secret - an ordinary home refrigerator, the size of which is many times larger, has the same power. Well, okay, now is not about that. Check its effectiveness. For example, we set it the minimum task to cool a glass of water with a room temperature of 26 degrees. For the operation of the refrigerator, we will use a power supply that is ideally suited for its parameters. Additionally, a wattmeter will be placed in the circuit. It will display current, voltage and power in real time. But the most important thing is consumption, the so-called watt per hour. Thus, we can approximately estimate the energy consumption of our refrigerator.

Turn on and see, everything works great. Here is a current of 4.29 A. The voltage is 11.15 Volts. Power 47.9 watts. 0.1 Watt-hours.

While the process is going on, we will conduct a more visual experiment that will show what exactly happens in the refrigerator. When we apply a constant current to the element, it will begin to pump heat from one side to the other.

By the way, if you change the direction of the current, the direction of heat transfer will also change, which is very convenient. The main thing is not to forget about active cooling, because fifty watts of electrical power heats the element instantly. The more efficiently we remove heat from the hot side, the colder the other.

As you can see, on the very surface of the module, water freezes very quickly, well, it would be so much energy.

But back to our refrigerator. After one hour of operation, the air temperature inside dropped to fifteen degrees, and at the water dropped to 20. It was surprising that in an hour of operation he ate clearly 48 watts. Two hours later, the air had 13 degrees, and the water had 17. Finally, after three hours of operation, the air temperature stopped at 13 degrees, and in a glass of water it was 15 and below 12 it will not drop. Well, so-so refrigerator, given that it was not full of drinks. But at the same time, this monster consumed 140 watts. For a home network, it may not be much, but for a car battery this is already quite noticeable. Therefore, there is only one element. Because no more battery just pulls. And this means that the efficiency of such a module is negligible - literally a few percent, which again depends on the manufacturer. Such a refrigerator is more like a good thermos. If they had taken cold food from home, then he would simply not have allowed them to heat up quickly. Making such refrigerators large is energetically disadvantageous.

When is Peltier effective?

By the way, this also applies to home-made people trying to make automobile air conditioners on this principle. There are more efficient technologies, but using Peltier elements to cool something small and compact is just the perfect solution. There is a whole range of such devices, for example, cooling processors or microcircuits of various small-sized devices. This is most likely the most important plus of such elements. They are miniature and minimal in weight. Compared with the same photocells, Peltier certainly has more minuses, but the effect itself certainly deserves attention. In the end, it all depends on the tasks being solved, and if the energy is free, then a high efficiency is not so important.

How many degrees can an element be cooled? About it .

Conclusion

Peltier modules, popular among radio amateurs and engineers, are electronic elements that are actively used for cooling and generating electricity. On their basis, power sources are developed for lighting or charging devices in camp conditions, mobile compact refrigerators for cars. There are attempts to use for cooling computer processors. The operation of the devices is based on 2 mechanisms: when one side of the Peltier plate is heated and the second is cooled, an electric current is generated; when electricity is supplied to the contacts, one side of the plate is cooled, the other is heated.

What is a Peltier element - an electric, thermal converter, which consists of several pairs (in some cases, one) of semiconductors of different types (“n” and “p”), the latter are connected by jumpers made of metal - mainly copper. In practice, this device creates a temperature difference at different ends of the surface when electric current flows.

One of the simplest versions of this Peltier device in practical use is the modification TEC1-12706, shown in Figure 1.

The principle of operation is based on the thermoelectric Peltier effect. In other words, during the flow and under the influence of an electric current, a temperature difference is created at the points of contact of thermocouples - semiconductors of "n" and "p" type.

Peltier elements - still satisfied with “sensitive devices” to overheat and high temperatures. They are subject to high operational requirements, if not met, the device quickly fails. It is very important to remove heat, for this purpose it is necessary to install a radiator or fan, otherwise the temperature of the cold side is not reached relatively hot.

How the Peltier Element Works

Imagine that an electric current passes through a thermal pair, as shown in Figure 2.

In this case, there is a process of heat energy absorption at the n - p semiconductor contact and a process of heat energy release at the p - n contact. As a result, the part of the semiconductor thermocouple that interfaces with the n - p contact will be cooled, and the second part, on the other opposite side, will be heated accordingly.

In the case when we change the polarity in current, the processes of heating and cooling occur, respectively, will also change.

The reverse process of the Peltier effect leads to the fact that when heat is supplied to one side of the thermal converter, electric current energy is obtained.

Of course, in practice, the use of one thermocouple is not enough to completely remove heat energy, so a large amount is used in the converter. An electrical circuit is assembled from thermocouples in series. At the same time, in the construction of thermoconverting elements: heating thermocouples are located on the other side relative to the cooling ones.

The device of the Peltier element is very simple. Thermal pairs are constructed between two platinum made of ceramic. Thermocouple connection is made by copper conductors (busbars). The number of thermocouples is determined by the purpose of the thermocouple, its power and installation location and can be used from one to several hundred pieces.

The main elements of the thermal converter are: p-type semiconductors, n-type semiconductors, ceramic plates, copper couplers - conductors; contacts for supplying electric current “plus” and “minus”. For the Peltier element, the temperature difference of the different edges of the thermocouples reaches up to 70 degrees Celsius. To increase this difference, it is necessary to increase the cascade of series connection of thermocouples.

The main operational characteristics of the Peltier element

This device as a whole works ideally in cases where thermocouples are in good and reliable contact with a cooling device, whether it be a cooling radiator or a cooling fan with a coil, that is, good heat removal.

Peltier modules, as they are often called, are very sensitive to current and voltage drops (not more than 5%). Under the influence of high temperatures (the most critical for elements up to 150 degrees), the efficiency decreases many times (up to 40%) and the module breaks very quickly.

As a rule, in the operation scheme of semiconductor elements, an unacceptable condition is the adaptation of relay devices: limiting power or regulating. This leads to the degradation of crystalline components and to malfunction in the near future element.

Frequent switching on and off of devices also negatively affects the operation and life of the device, and its durability. According to the laws of physics, any heating of a material leads to its thermal expansion, and cooling leads to compression. Accordingly, especially weak spots in semiconductor elements are “solder”, where, due to mechanical motion, the appearance of defects in the form of microcracks and, ultimately, to chain breaking.

The thermal conductivity coefficient of the thermal pairs of the Peltier element is high enough, which on the one hand is an advantage, and on the other hand limits the service life and the estimated number of stop-start-stop cycles.

Advantages and disadvantages of the Peltier module

It is basically impossible and impractical to compare a Peltier device with other cooling units with a different drive, since in the first case they have semiconductor materials in the form of crystals, and in the second case the working fluid is gas or liquid (for example: a compressor refrigerator). In various areas, both are used.

The advantages of Peltier elements include:

- the complete absence of mechanics of motion and rotating parts, as well as liquids, gases;

- absolutely no noise from the operation of devices;

- relatively small sizes;

- bifunctionality: heating and cooling when changing polarity;

The disadvantages include:

- relatively low efficiency;

- requirement of a constant source of energy, power;

- the number of starts and stops is limited;

- smooth disconnection and inclusion of thermoelectric devices;

- control of heating on the one hand or cooling on the other with a fan.

Poll: Is it clear what is Peltier Element and how it works

A Peltier element is a thermocouple, in other words, a device that changes temperature and works in accordance with the Peltier principle of the same name, that is, demonstrating the temperature difference that occurs from the moment of supply of electricity. In English sources it appears as a thermoelectric cooler. The inverse of this effect is called the Seebeck effect.

The principle of operation of the device

The Peltier element operates due to the interaction of one conductive material with another, different in the energy level of electrons in the conductive region. Passing through such a communication channel gives the electron a large energy reserve, which then allows it to go into the conducting region with a higher energy level. The absorption of this energy leads to a decrease in temperature at the point of connection of the conductors. When the reverse current flows, the contact heats up, which finds expression in the form of a standard thermal effect.

Provided that a heat sink is connected on one side, during operation of the radiator system, the second side gives strong cooling (up to tens of degrees below the ambient temperature level). A direct relationship is observed between the magnitude of the current and the degree of cooling. When changing polarity, the positions of the sides of heating and cooling also change.

When a Peltier element interacts with parts made of metal, the effect exerted by it decreases many times, and the temperature contrast becomes little noticeable under the influence of various phenomena associated with the thermal conductivity of the circuit. For this reason, practical application involves the use of two semiconductors at once.

You can combine thermocouples in any quantities within hundreds, which makes it possible to create a Peltier element of any refrigerating capacity.

Thermoelectric module

The Peltier effect can be observed especially clearly when using p- and n-semiconductors. In accordance with the direction of the electric current, when passing through the pn compound, absorption or energy release takes place.

It is this design that is used in TEM (thermoelectric module). A single element of a thermoelectric module is one whose design is a combination of a p- and n-conductor. If several similar elements are connected in series, then the absorption of heat will occur at the n-p-contact, and the release at the p-n-contact. As a result, the previously described situation with a temperature difference arises. According to the generally accepted principle, the side to which the wires are connected is hot and in the diagram it is always located below.

Fig. 1: Peltier thermoelectric module

In TEM, thermocouples are fixed between a pair of plates of ceramic materials. Each of the branches is soldered with copper conductive pads (busbars), which in turn are bonded to a heat-conducting material, for example, aluminum oxide.

Determine the level of the operating voltage of the module should be based on the number of components. The most common option is 127-pair modular designs with the highest voltage level of 16 volts. But 75% of this value is usually enough for their work. Moreover, this figure is the most suitable, since it also meets the requirements for working conditions, and is quite economical. With increasing voltage, the power will hardly increase, but power consumption will increase significantly.

Practical application

To date, the use of the Pelt element is especially relevant in devices of the following types:

- Refrigerators;

- Air conditioners;

- Car coolers;

- Water coolers;

- Video cards for a personal computer.

In general, it can be said that the Peltier element has become an integral part of a variety of refrigeration and air conditioning systems. Using this device is an excellent approach to solving the problem of equipment overheating. Currently, the Peltier element can also be used to cool the acoustic and sound system, since its operation is completely silent and ideal for such purposes.

There are several qualities of the Peltier element that are in great demand:

- They provide a fairly powerful heat transfer;

- They have very modest sizes, which allows you to use them in almost any device;

- Able to maintain the same temperature over a long period of time (thanks to radiators);

- They have a considerable durability, as they are equipped with a number of solid immovable components.

The simplest component of the element looks like a pair of copper conductors to which contacts are connected, connecting wires equipped with an insulating element (stainless steel or ceramic is used for its manufacture).

How to make a Peltier element yourself

The simplicity of the design of this device has to do it yourself. Moreover, the scope of its practical application is practically unlimited: refrigerators, air conditioners and other equipment.

Previously, you should prepare a pair of metal plates, and you will also need wiring with contacts. First of all, stock up with conductors to be installed near the base of the device. For these purposes, PP conductors are best suited.

Next, do not forget that semiconductors must be installed at the output, which will supply heat to the upper plate. To mount the element, you need a soldering iron. At the final stage, you need to connect a pair of wires. One is localized near the base and securely mounted next to the outermost conductor. It is important that there is no contact with the plate.

The attachment point of the second conductor is located near the upper part and is fixed in the same way - at the extreme conductor.

To check the item for performance, you will need to use a tester. The device is connected to the wires and the voltage is measured. The standard voltage deviation reaches approximately 23 volts.

The power of the Pelt element is directly dependent on its dimensions, this should be taken into account when assembling or installing it yourself. Installing an insufficiently powerful element will not prevent the breakdown of equipment, but only delay it. At the same time, excess power causes the temperature level to drop to a critical level, when moisture in the air can begin to condense and settle on the surface of devices, which is especially dangerous for electronic devices.

In addition, the other side of the module is a source of a sufficiently large amount of heat, therefore, to ensure its safe operation, a rather large fan is required.

How to make a generator based on a Peltier element?

Generators based on the Peltier element are especially interested in people who, because of their sufficiently long isolation from civilization, need a simple and affordable source of energy. They are also widely used for critical overheating of personal computer parts.

Fig. 2: Peltier-based generator.

Peltier elements have a rather interesting principle of action, but in addition they have one curious feature: if a temperature difference is attached to them, then they produce electricity. One of the options for a generator based on this device involves the following design:

Steam flows through two tubes (one for entry and one for exit), which is sent to the cavity of the heat exchanger constructed of a plate (material: aluminum), which has a thickness of 1 cm.

A connection with one channel is connected to each opening of the heat exchanger. The dimensions of the heat exchanger exactly duplicate the dimensions of the Peltier elements. Two elements are fixed on two sides of the heat exchanger with four screws (2 on each side). As a result, thanks to the openings and tubules of the heat exchanger, a complete system of communicating departments is formed through which steam passes. Moving forward, steam enters the chamber through one tube and exits through another, moving to the next chamber. The heat transmitted by the steam goes to the Peltier elements when the steam comes in direct contact with their surface, as well as with the material of the heat exchanger.

To close the elements against the body of the heat exchanger, as well as to organize the removal of thermal energy to the "cold" side, aluminum plates are used 0.5 cm thick. At the last stage, the entire structure is sealed with silicone sealants.

After that, steam is released through the tubes, and the structure is immersed in cold water. The whole system begins to work. Electric current will be generated until the difference between the temperature of the “hot” and “cold” sides is reduced to a minimum.

There is a more elementary method.

The Peltier element with the leads connected to the charging telephone cable is mounted on an aluminum radiator (which will contact the “cold” side) with the help of a sealant. On top of the device is any hot item, such as a mug of hot tea. After a couple of seconds, the phone can be charged. Charging will continue until the tea has cooled.

Write comments, additions to the article, maybe I missed something. Take a look at it, I will be glad if you find anything else useful on mine.

Refrigeration equipment has become so firmly entrenched in our lives that it’s even hard to imagine how one could manage without it. But classic refrigerant designs are not suitable for mobile use, for example, as a travel cooler bag.

For this purpose, installations are used in which the operating principle is based on the Peltier effect. Briefly tell about this phenomenon.

What it is?

By this term is meant a thermoelectric phenomenon discovered in 1834 by the French natural scientist Jean-Charles Peltier. The essence of the effect is the generation or absorption of heat in the area where dissimilar conductors come in contact through which electric current passes.

In accordance with the classical theory, the following explanation of the phenomenon exists: an electric current transfers electrons between metals, which can accelerate or slow down its motion, depending on the contact potential difference in conductors made of various materials. Accordingly, with an increase in kinetic energy, its conversion to heat occurs.

On the second conductor, the reverse process is observed, requiring replenishment of energy, in accordance with the fundamental law of physics. This is due to thermal vibration, which causes cooling of the metal of which the second conductor is made.

Modern technologies allow the manufacture of semiconductor module elements with maximum thermoelectric effect. It makes sense to briefly talk about their design.

Device and principle of operation

Modern modules is a design consisting of two insulator plates (usually ceramic), with thermocouples connected in series between them. A simplified diagram of such an element can be found in the figure below.

Designations:

- A - contacts for connecting to a power source;

- B is the hot surface of the element;

- C is the cold side;

- D - copper conductors;

- E is a p-junction semiconductor;

- F is an n-type semiconductor.

The design is made in such a way that each side of the module contacts either p-n or n-p junctions (depending on polarity). The pn contacts are heated, and the np contacts are cooled (see Fig. 3). Accordingly, a temperature difference (DT) occurs on the sides of the element. For the observer, this effect will look like the transfer of thermal energy between the sides of the module. It is noteworthy that changing the polarity of the supply leads to a change in the hot and cold surfaces.

Fig. 3. A - hot side of thermocouple, B - cold

Fig. 3. A - hot side of thermocouple, B - cold Specifications

The characteristics of thermoelectric modules are described by the following parameters:

- cooling capacity (Q max), this characteristic is determined on the basis of the maximum allowable current and the temperature difference between the sides of the module, measured in watts;

- the maximum temperature difference between the sides of the element (DT max), the parameter is given for ideal conditions, the unit of measurement is degrees;

- permissible current strength necessary to ensure maximum temperature difference - I max;

- the maximum voltage U max required for the current I max to achieve the peak difference DT max;

- internal resistance of the module - Resistance, indicated in Ohms;

- coefficient of efficiency - COP (acronym for English - coefficient of performance), in fact it is the efficiency of the device, showing the ratio of cooling to power consumption. For inexpensive elements, this parameter is in the range of 0.3-0.35, for more expensive models it approaches 0.5.

Marking

Consider how the typical labeling of the modules is decrypted using the example of Figure 4.

Figure 4. Peltier module marked TEC1-12706

Figure 4. Peltier module marked TEC1-12706 Marking is divided into three significant groups:

- The designation of the item. The first two letters are always unchanged (TE), they say that this is a thermocouple. The following indicates the size, there can be letters "C" (standard) and "S" (small). The last digit indicates how many layers (cascades) in the element.

- The number of thermocouples in the module shown in the photo is 127.

- The rated current in Amperes, we have 6 A.

The marking of other models of the TEC1 series is also read in the same way, for example: 12703, 12705, 12710, etc.

Application

Despite the rather low efficiency, thermoelectric elements are widely used in measuring, computing, as well as household appliances. Modules are an important working element of the following devices:

- mobile refrigeration units;

- small generators for generating electricity;

- cooling systems in personal computers;

- coolers for cooling and heating water;

- dehumidifiers, etc.

We give detailed examples of the use of thermoelectric modules.

Peltier refrigerator

Thermoelectric refrigeration units are significantly inferior in performance to compressor and absorption counterparts. But they have significant advantages, which makes it appropriate to use them under certain conditions. These benefits include:

- simplicity of design;

- resistance to vibration;

- lack of moving elements (with the exception of the fan blowing the radiator);

- low noise level;

- small dimensions;

- the ability to work in any position;

- long service life;

- low energy consumption.

These characteristics are ideal for mobile installations.

Peltier element as an electric power generator

Thermoelectric modules can work as generators of electricity if one of their sides is subjected to forced heating. The greater the temperature difference between the sides, the higher the current generated by the source. Unfortunately, the maximum temperature for the thermogenerator is limited, it cannot be higher than the melting point of the solder used in the module. Violation of this condition will lead to the failure of the element.

For mass production of heat generators, special modules with refractory solder are used, they can be heated to a temperature of 300 ° C. In ordinary elements, for example, TEC1 12715, the limitation is 150 degrees.

Since the efficiency of such devices is low, they are used only in cases where it is not possible to use a more efficient source of electrical energy. Nevertheless, 5-10 W heat generators are in demand among tourists, geologists and residents of remote areas. Large and powerful stationary installations operating on high-temperature fuel are used to power gas distribution devices, meteorological station equipment, etc.

To cool the processor

Relatively recently, these modules began to be used in CPU cooling systems of personal computers. Given the low efficiency of thermocouples, the benefits of such structures are quite doubtful. For example, to cool a heat source with a power of 100-170 W (which corresponds to most modern CPU models), it will be necessary to spend 400-680 W, which requires the installation of a powerful power supply.

The second pitfall - an unloaded processor will generate less thermal energy, and the module can cool it less than the dew point. As a result, condensation will begin to form, which is guaranteed to disable the electronics.

Those who decide to create such a system on their own will need to conduct a series of calculations to select the power of the module for a specific processor model.

Based on the foregoing, to use these modules as a CPU cooling system is not cost-effective, in addition, they can cause the failure of computer equipment.

The situation is completely different with hybrid devices, where thermal modules are used in conjunction with water or air cooling.

Hybrid cooling systems have proven effective, but the high cost limits their circle of fans.

Peltier air conditioning

Theoretically, such a device will be structurally much simpler than classical climate control systems, but everything comes down to low productivity. It is one thing to cool a small volume of the refrigerator compartment, another is a car’s room or interior. Air conditioners on thermoelectric modules will consume more electricity (3-4 times) than refrigerant equipment.

As for the use of climate control as an automobile system, the capacity of a regular generator will not be enough for the operation of such a device. Replacing it with more efficient equipment will lead to significant fuel consumption, which is not cost-effective.

Discussions on this topic periodically arise in thematic forums and various home-made designs are considered, but a full-fledged working prototype has not yet been created (apart from the air conditioner for the hamster). It is quite possible that the situation will change when modules with more acceptable efficiency appear in the public domain.

For cooling water

A thermoelectric element is often used as a cooler for water coolers. The design includes: a cooling module, a thermostat-controlled controller and a heater. Such an implementation is much simpler and cheaper than the compressor circuit; in addition, it is more reliable and easier to operate. But there are certain disadvantages:

- water does not cool below 10-12 ° C;

- it takes longer to cool than a compressor analogue, therefore, such a cooler is not suitable for an office with a large number of employees;

- the device is sensitive to external temperature, in a warm room the water will not cool to the minimum temperature;

- installation in dusty rooms is not recommended, as the fan may clog and the cooling module will fail.

Table water cooler using a Peltier element

Table water cooler using a Peltier element Peltier air dryer

Unlike an air conditioner, the implementation of an air dryer on thermoelectric elements is quite possible. The design is quite simple and inexpensive. The cooling module lowers the temperature of the radiator below the dew point, as a result, moisture contained in the air passing through the device settles on it. The settled water is discharged into a special storage.

Despite the low efficiency, in this case, the efficiency of the device is quite satisfactory.

How to connect?

There will be no problems with connecting the module, a constant voltage must be applied to the output wires, its value is indicated in the element datasheet. The red wire must be connected to the plus, the black wire to the minus. Attention! Polarity reversal swaps the cooled and heated surfaces.

How to check the Peltier element for performance?

The easiest and most reliable way is tactile. It is necessary to connect the module to the appropriate voltage source and touch its different sides. A workable element will have one of them warmer and the other colder.

If there is no suitable source at hand, you will need a multimeter and a lighter. The verification process is quite simple:

- we connect probes to the module outputs;

- we bring the lit lighter to one of the sides;

- observe the readings of the device.

In the working module, when one of the sides is heated, an electric current is generated, which will be displayed on the instrument panel.

How to make a Peltier element with your own hands?

It is almost impossible to make a home-made module at home, all the more it makes no sense, given their relatively low cost (about $ 4- $ 10). But you can assemble a device that will be useful in a hike, for example, a thermoelectric generator.

To stabilize the voltage, it is necessary to assemble a simple converter on the IC chip L6920.

A voltage in the range of 0.8-5.5 V is applied to the input of such a converter; at the output it will produce stable 5 V, which is quite enough to recharge most mobile devices. If a regular Peltier element is used, it is necessary to limit the working range of the temperature of the heated side to 150 ° C. In order not to bother tracking, it is better to use a pot of boiling water as a heat source. In this case, the element is guaranteed not to heat above 100 ° C.