In the year 1991.

Encyclopedic YouTube

-

1 / 5

The characteristics of lithium-ion batteries depend on the chemical composition of the constituent components and vary within the following limits:

- unit cell voltage:

- nominal: 3.7 (for batteries with a maximum voltage of 4.35, the nominal voltage is 3.8) (when discharged to the middle of the capacity with current, equal to one fifth of the capacity of the battery);

- maximum: 4.23 or 4.4 (for batteries at 4.35);

- minimum: 2.5-2.75-3.0 (depending on capacity and maximum voltage);

- specific energy consumption: 110 ... 243 W / kg;

- internal resistance: 5 ... 15 Ohm /;

- number of charge / discharge cycles until reaching 80% capacity: 600;

- fast charge time: 15 min ... 1 hour;

- self-discharge at room temperature: 3% per month;

- load current relative to capacity FROM presented in:

- permanent: up to 65 FROM;

- pulse: up to 500 FROM;

- optimal: up to 1 FROM;

- operating temperature range: from −20 ° C to +60 ° C (the most optimal +20 ° C);

Due to excess voltage during charging, the battery may catch fire, therefore, a battery charge controller is built into the battery case, which protects the battery from excess charge voltage. Also, this controller can optionally control the temperature of the battery, turning it off when overheating, to limit the depth of discharge and current consumption. However, keep in mind that not all batteries are protected. In order to reduce production costs or increase capacity, manufacturers may not install it.

Lithium batteries have special requirements when connecting several cans in series. Chargers for such multi-bank batteries are supplied balancing schemecells. The meaning of balancing is that the electrical properties of the cans may differ slightly, and some bank will reach full charge before others. In this case, it is necessary to stop the charge of this can, while continuing to charge the rest. This function is performed by a special battery balancer. He shunts a charged jar so that the charge current goes past it.

Chargers can maintain a final charge voltage in the range of 4.05-4.2 to detect the presence of a battery.

Device

A lithium-ion battery consists of electrodes (cathode material on aluminum foil and anode material on copper foil) separated by a porous separator impregnated with an electrolyte. The electrode package is placed in a sealed enclosure, the cathodes and anodes are connected to the current collector terminals. The casing is sometimes equipped with a safety valve that relieves internal pressure in case of emergency or violation of operating conditions. Lithium-ion batteries vary in the type of cathode material used. The charge carrier in a lithium-ion battery is a positively charged lithium ion, which has the ability to incorporate (intercalate) into the crystal lattice of other materials (for example, graphite, metal oxides and salts) with the formation of a chemical bond, for example: graphite with the formation of LiC 6, oxides (LiMnO 2) and salts (LiMn RON) of metals.

Initially, lithium metal was used as negative plates, then coal coke. In the future, graphite was used. The use of cobalt oxides allows batteries to operate at significantly lower temperatures, increases the number of discharge / charge cycles of one battery. The proliferation of lithium iron phosphate batteries is due to their relatively low cost. Lithium-ion batteries are used in conjunction with a control and management system - SKU or BMS (battery management system), and a special charge / discharge device.

Currently, three classes of cathode materials are used in the mass production of lithium-ion batteries:

- lithium cobaltate LiCoO 2 and solid solutions based on isostructural lithium nickelate

- lithium manganese spinel LiMn 2 O 4

- lithium ferrophosphate LiFePO 4.

Electrochemical schemes of lithium-ion batteries:

- lithium cobalt LiCoO 2 + 6C → Li 1-x CoO 2 + LiC 6

- lithium ferro-phosphate LiFePO 4 + 6C → Li 1-x FePO 4 + LiC 6

Due to the low self-discharge and a large number of charge / discharge cycles, Li-ion batteries are most preferred for use in alternative energy. At the same time, in addition to the SKU system, they are equipped with inverters (voltage converters).

Benefits

- High energy density (capacity).

- Low self discharge.

- No maintenance required.

disadvantages

1. First-generation Li-ion batteries were explosive. This was explained by the fact that they used an anode of metallic lithium, on which spatial structures (dendrites) appeared during multiple charging / discharging cycles, leading to electrode closure and, as a result, fire or explosion. This drawback was finally eliminated by replacing the anode material with graphite. Similar processes took place at the cathodes of lithium-ion batteries based on cobalt oxide in violation of operating conditions (recharge). Lithium-ferro-phosphate batteries are completely devoid of these disadvantages. In addition, all modern lithium-ion battery chargers prevent overcharging and overheating due to overcharging.

Loss of storage capacity:

Temperature, ⁰C With 40% charge,% per year With 100% charge,% per year 0 2 6 25 4 20 40 15 35 60 25 40% for three months Discharging at low temperatures leads to a reduction in the energy delivered, especially at temperatures below 0 ⁰C. Thus, a decrease in the supply of energy supplied with a decrease in temperature from +20 ⁰C to +4 ⁰C leads to a decrease in the energy supplied by ~ 5-7%, a further decrease in the discharge temperature below 0 ⁰C leads to a loss of energy supplied by tens of percent and can lead to premature exhaustion resource. The chemistry of lithium-ion batteries is more sensitive to charging temperatures, and it is optimal at temperatures of ~ +20 ⁰C, and at temperatures below +5 ⁰C is not recommended.

Memory effect

According to research by scientists from the Paul Scherer Institute (Switzerland), it was found that lithium-ion batteries have a memory effect. According to the authors of the study, for Li-Ion batteries:

... in fact, the effect is tiny: the relative deviation in voltage is only a few units per thousand.

Original text

The effect is in fact tiny: the relative deviation in voltage is just a few parts per thousand.

We are talking exclusively about the fundamental presence of the effect, and not about its any significant effect on the battery.

The key idea of \u200b\u200bthe study was to search for the effect as such.

Original text

But the key was the idea of \u200b\u200blooking for it at all.

As the study showed, frequent cycles of incomplete charging and subsequent discharge lead to the appearance of separate "microeffects of memory", which are then summed up. This is because the basis of the battery is the release and re-capture of lithium ions, the dynamics of which deteriorate in case of incomplete charging.

During charging, lithium ions leave particles of lithium ferrophosphate, the size of which is tens of micrometers, one after another. The cathode material begins to separate into particles with different lithium contents. Charging the battery occurs against the background of increasing electrochemical potential. At a certain point, it reaches its limit value. This leads to an acceleration of the release of the remaining lithium ions from the cathode material, but they no longer change the total battery voltage.

If the battery is not fully charged, then a certain number of particles close to the boundary state will remain at the cathode. They almost reached the barrier of lithium ion release, but did not manage to overcome it. During the discharge, free lithium ions tend to return to their place and recombine with ferrophosphate ions. However, on the cathode surface, they are also met by particles in the boundary state that already contain lithium. Re-capture is hindered, and the microstructure of the electrode is disturbed.

Currently, two ways to solve the problem are being examined: making changes to the algorithms of the battery management system and developing cathodes with an increased surface area.

An important role in the durability and proper operation of the battery is played by its operation. Many experts identify two simple rules that can help extend battery life:

Aging

The temperature regime of the charge of lithium-polymer and lithium-ion batteries affects their capacity: the capacity decreases when charging in the cold or in hot weather. Deep discharge completely destroys the lithium-ion battery. Also, the battery’s life cycle is affected by the depth of its discharge before the next charge and charging with currents higher than those set by the manufacturer. They are extremely sensitive to charging voltage. If it is increased by only 4%, then the batteries will lose twice the capacity from cycle to cycle. The charging current depends on the voltage difference between the battery and the charger and on the resistance of both the battery itself and the wires connected to it. Therefore, an increase in the charging voltage by 4% can lead to an increase in the charging current by 10 times. This negatively affects the battery. It can overheat and degrade. Optimum storage conditions for Li-ion batteries are achieved with a 40% charge of the battery capacity and a temperature of 0 ... 10 ° C. Lithium batteries age even when not in use. After 2 years, the battery loses about 20% of its capacity. Accordingly, there is no need to buy a battery "in reserve" or excessively get carried away by the "saving" of its resource. When buying, it is worth looking at the production date to know how much this power source has already lain in the warehouse. If more than two years have passed since the time of manufacture, it is better to refrain from buying.

Decrease in capacity at low temperatures

When the ambient temperature drops below 0 ° C, the power of the lithium-ion battery decreases to 40-50%. Owners of wearable electronics are least affected by the negative effects of using equipment at low temperatures, and the industry segments involved in the production of unmanned aerial vehicles, robotic systems and space technology, are in dire need of new heated batteries. To solve this problem, the design of batteries with internal heating.

Explosion hazard

Lithium batteries occasionally exhibit a tendency to explosive spontaneous combustion. The intensity of combustion, even from miniature batteries, is such that it can lead to serious consequences. Airlines and international organizations are taking measures to limit the transport of lithium batteries and devices with them on air transport.

Spontaneous combustion of a lithium battery is very difficult to extinguish by traditional means. In the process of thermal acceleration of a faulty or damaged battery, there is not only the release of stored electrical energy, but also a series of chemical reactions that release energy for self-heating, oxygen and combustible gases. Therefore, a flashed battery is capable of burning without access to air, and means of isolation from atmospheric oxygen are not suitable for extinguishing it. Moreover, lithium metal actively reacts with water to form a combustible hydrogen gas, therefore quenching lithium batteries with water is effective only for those types of batteries where the mass of the lithium electrode is small. In general, extinguishing a lit lithium battery is inefficient. Extinguishing target to reduce battery temperature and prevent flame spread

For a long time, an acid accumulator was the only device capable of providing autonomous objects and mechanisms with electric current. Despite the large maximum current and minimum internal resistance, such batteries had a number of drawbacks that limited their use in devices consuming a large amount of electricity or in enclosed spaces. In this regard, lithium-ion batteries are devoid of many negative qualities of their predecessors, although they have drawbacks.

Content

What is a lithium ion battery

The first lithium batteries appeared 50 years ago. Such products were an ordinary battery in which a lithium anode was installed to increase the level of power output. Such products had very high operational characteristics, but one of the most serious drawbacks was the high probability of lithium ignition during cathode overheating. Given this feature, scientists have over time replaced the pure element with metal ions, resulting in significantly increased safety.

Modern li-ion batteries are very reliable and able to withstand a large number of charge-discharge cycles. They have a minimal memory effect and relatively low weight. Due to these properties, a lithium battery is widely used in many devices. The product can be used as a battery, in the form of batteries for household appliances, as well as a highly efficient traction power source.

Today, such devices have several disadvantages:

- high cost;

- do not like deep discharges;

- may die at low temperatures;

- lose capacity when overheating.

How is the production of li-ion batteries

Lithium-ion batteries are produced in several stages:

- The manufacture of electrodes.

- Combining electrodes into a battery.

- Installing the protection board.

- Install the battery in the case.

- Electrolyte filling.

- Testing and charge.

At all stages of production, technology and safety measures must be followed, which ultimately allows you to get a quality product.

As a cathode in lithium-ion batteries, a foil is used with a substance containing lithium deposited on its surface.

The following lithium compounds can be used, depending on the purpose of the battery:

- LiCoO2;

- LiNiO2;

- LiMn2O4.

In the manufacture of cylindrical power sources of sizes AA and AAA, the main electrode is twisted into a roll, which is separated from the anode by a separator. With a large area of \u200b\u200bthe cathode, the film of which has a minimum thickness, it is possible to achieve high energy intensity of the product.

The principle of operation and device li-ion battery

The lithium-ion battery operates as follows:

- When a constant electric current is supplied to the battery contacts, lithium cations move into the anode material.

- During discharge, lithium ions leave the anode and penetrate the dielectric to a depth of 50 nm.

In the “life” of a lithium-ion battery, such cycles can be up to 3,000, while the battery can give off almost all the electric current accumulated during charging. Deep discharge does not lead to oxidation of the plates, which favorably distinguishes such products in comparison with acid batteries.

Not all li-ion batteries tolerate deep discharges well. If such a battery is installed in the phone or camera (type AAA), then when the battery is deeply discharged, the controller board will block the possibility of charging the battery for safety reasons, therefore, it cannot be charged without a special charger. If this is a traction lithium battery for an outboard motor, then a deep discharge will not be at all frightening to it.

Unlike finger-type batteries, complex batteries consist of several separate sources of electricity connected in parallel or in series. The connection method depends on what indicator of electricity needs to be increased.

Sizes and types of li-ion batteries

Lithium-ion batteries are widespread. Such sources of electric current are used in various household devices, gadgets and even cars. In addition, industrial lithium-ion batteries are manufactured, which have a large capacity and high voltage. The most popular are the following types of lithium batteries:

Title Diameter mm Long mm Capacity mAh 10180 10 18 90 10280 10 28 180 10440 (AAA) 10 44 250 14250 (AA / 2) 14 25 250 14500 14 50 700 15270 (CR2) 15 27 750-850 16340 (CR123A) 17 34.5 750-1500 17500 (A) 17 50 1100 17670 17 67 1800 18500 18 50 1400 18650 (168A) 18 65 2200-3400 22650 22 65 2500-4000 25500 (type C) 25 50 2500-5000 26650 26 50 2300-5000 32600 (type D) 34 61 3000-6000 The first two digits of such designations indicate the diameter of the product, the second pair - the length. The last “0” is set if the batteries are cylindrical.

In addition to cylindrical-shaped batteries, the industry also produces “” type batteries with a voltage of 9v and powerful industrial batteries with a voltage of 12v, 24v, 36v and 48v.

Stacker battery

Stacker battery Depending on the elements that are added to the product, the following markings may appear on the battery case:

- ICR - containing cobalt;

- IMR - - - - manganese;

- INR - - - - nickel and manganese;

- NCR - - - - nickel and cobalt.

Lithium batteries differ not only in size and chemical additives, but primarily in capacity and voltage. These two parameters determine the possibility of their use in various types of electrical appliances.

Where are li-ion batteries used?

Lithium-ion batteries have no alternative where you need a battery capable of delivering electricity in almost full volume, and make a large number of charge / discharge cycles without reducing capacity. The advantage of such devices is their relatively low weight, because there is no need to use lead grids in such devices.

Given the high performance characteristics, such products can be used:

- As starter batteries. Lithium batteries for cars are getting cheaper every year, thanks to new developments that can reduce production costs. Unfortunately, the price of such batteries can be very high, which is why many car owners cannot afford such a battery. The disadvantages of lithium-ion batteries include a significant drop in power at temperatures below minus 20 degrees, so the operation of such products in the northern regions will be impractical.

- As traction devices. Due to the fact that lithium-ion batteries easily carry a deep discharge, they are often used as traction for boat electric motors. If the engine power is not too large, then one charge is enough for 5-6 hours of continuous operation, which is quite enough for fishing or taking a boat trip. Traction lithium-ion batteries are also installed on various loading equipment (electric stackers, electric forklifts) operating in enclosed spaces.

- In household appliances. Lithium-ion batteries are used in various household devices instead of standard batteries. Such products have a voltage of 3.6v - 3.7v, but there are models that can replace a regular salt or alkaline battery with 1.5 Volts. You can also meet 3v batteries (15270,), which can be installed instead of 2 standard batteries.

Such products are used mainly in powerful devices in which conventional salt batteries discharge very quickly.

Traction Battery

Traction Battery Li ion battery operating instructions

The life of a lithium battery is influenced by many factors, the knowledge of which will significantly increase the resource. When using this type of battery, you must:

- Try not to let the battery run out completely. Despite the high resistance of the battery to such an impact, it is advisable not to squeeze all the “juices” out of it. Particular care should be taken when operating such batteries with UPS and high power electric motors. If a full discharge of the battery has occurred, it is necessary to immediately revive it, that is, connect it to a special charger. You can also recharge the battery after a long stay in a deep discharge state, for which it is necessary to make a high-quality charge for 12 hours, then discharge the battery.

- Do not overcharge. Overcharging negatively affects product performance. The built-in controller is not always able to turn off the battery in time, especially when charging is carried out in a cold room.

In addition to overcharging and over-discharging, the battery should be protected from excessive mechanical influences, which can lead to depressurization of the case and fire to the internal components of the battery. For this reason, there is a prohibition on mailing batteries in which the content of pure lithium exceeds 1 g.

Used as a battery for screwdrivers, laptops and phones

Used as a battery for screwdrivers, laptops and phones How to store lithium-ion batteries

If there is a need for long-term storage of lithium-ion batteries, then to minimize the negative impact on the products, you must adhere to the following recommendations:

- Store the product only in a cool, dry place.

- The battery must be removed from the electrical device.

- The battery must be charged before preservation. The minimum voltage at which internal corrosion processes will not form is equal to 2.5 volts per 1 cell.

Given the small self-discharge of such batteries, it is possible to store the battery in this way for several years, but during this period the capacity of the cell will inevitably decrease.

Disposal of lithium-ion batteries

Lithium-ion batteries contain substances hazardous to health, so in no case should they be taken apart at home. After the battery runs out of life, it must be returned for further processing. In specialized reception centers, you can receive monetary compensation for an old lithium battery, because such products contain expensive elements that can be reused.

What are the types of lithium batteries and their design features?

Lithium batteries in the modern market have firmly occupied several different niches. They are mainly used in all kinds of consumer electronics, portable tools and mobile devices, household appliances, etc. There are even 12 volt lithium batteries for cars. Although widespread in the automotive industry, they have not yet received. The use of lithium batteries in various sectors of the economy has led to the appearance on the market of many varieties of these batteries. The main types of lithium batteries we will consider in today's article.

Here we will not write about the principle of operation of Li rechargeable batteries and the history of their occurrence. Details can be found in the article at the specified link. You can also read the materials separately about and. And in this material I would like to consider precisely the different types of Li batteries, depending on their characteristics and purpose.

So, as for the power and capacity of lithium batteries. The division is rather arbitrary. In order to produce batteries of different capacities, with different discharge currents, manufacturers change a number of parameters. For example, they control the thickness of the electrode mass layer on the foil (in the case of a roll construction). In most cases, this electrode layer is applied with copper (minus electrode) and aluminum (plus) foil. Due to this increase in the electrode layer, the specific parameters of the battery increase.

However, when building up the active mass, it is necessary to reduce the thickness of the conductive base (foil). As a result, the battery can pass less current without overheating. In addition, an increase in the electrode mass layer leads to an increase in the resistance of the cell. To reduce resistance, often more active and dispersed substances are used for the active mass. Manufacturers “play” with these parameters when releasing batteries with one or another parameter. A thin foil battery with a thick active mass shows high values \u200b\u200bof stored energy. And its power will be low, and vice versa. And this can be adjusted without changing the size of the product.

Rechargeable batteries with different values \u200b\u200bof capacity and discharge current are obtained by changing the following parameters:

- Foil thickness;

- Separator thickness;

- Material of plus and minus electrode;

- Particle size of the active mass;

- The thickness of the electrode.

At the same time, battery models designed for higher power are equipped with current leads of large sizes and weights. This is to prevent overheating. Also, to increase the discharge current, all kinds of substances are used that are added to the electrolyte or to the electrode mass. For batteries with a large capacity, the current outputs are usually small. They are designed for discharge current up to 2C (usually the charge-discharge current of the battery is indicated from its capacity) and charging ─ up to 0.5C. For lithium batteries of high capacity, these values \u200b\u200bare up to 20C and up to 40C, respectively.

High power lithium battery models are designed to power starters, with high capacity - to power various portable equipment. As for the development of lithium batteries, manufacturers of all kinds of electronics order them in special firms. Those develop them taking into account the proposed conditions, and then place them in mass production. When developing modern lithium batteries, the following parameters are taken into account:

- Capacity;

- Regular and maximum discharge current;

- Sizes

- Location conditions inside the device;

- Working temperature;

- Resource (number of charge-discharge cycles) and others.

Various designs of lithium batteries

According to the design features of lithium batteries can be divided into two signs:

- Housing design;

- Electrode design.

Electrode Design

Roll type

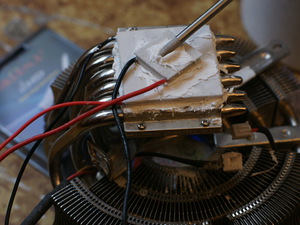

In the image below you can see the Li─Ion battery with a roll type design.

Elements of a roll design are made of two types:- A roll of electrodes twists around a virtual plate. In one case several rolls connected in parallel can be placed;

- Cylindrical. Different heights and diameters.

Roll construction is used where a small capacity battery and power are required. This technology has a small amount of labor, since the twisting of the electrode strips and the separator is fully automated. The disadvantage of this design is poor heat removal from the electrodes. In fact, heat is removed only through the end face of the element.

From a set of electrodes

Lithium batteries with an assembly of individual electrodes are used in the production of prismatic batteries.

Heat is also removed here from the end of the electrode. Manufacturers are trying to improve heat dissipation by adjusting the composition and dispersion of the active mass.

Housing design

Cylindrical

Attention should be paid to cylindrical lithium batteries. They are widely distributed in various household appliances and electronics. Battery cells are especially popular.

As the advantages of a cylindrical body, experts call the absence of a change in volume during prolonged use. This is due to the fact that the battery changes a little during the charge-discharge process. The design of the electrodes in such a housing is always of a roll type. The disadvantages include poor heat dissipation.

Cylindrical lithium batteries can have the following current outputs:

- Helical boron;

- Conventional pads.

Where higher requirements for current extraction are used, screw borons are used. This is a battery with a large discharge current and a large capacity (more than 20 Ah). Numerous tests show that cylindrical lithium batteries with helical boron can withstand currents of not more than 10-15C. And these are the values \u200b\u200bof the short-term load at which the element quickly overheats. With prolonged use, they withstand discharge currents of 2–3C. Mainly used in portable power tools.

Battery cells with contact pads are commonly used to combine into batteries. To do this, they are welded with a tape using resistance welding. Sometimes manufacturers already produce elements with petals for soldering. Moreover, the appearance of the petals may be different depending on the type of soldering.In the designation of the standard size of cylindrical lithium batteries, their sizes are usually present. For example, lithium ion cells 18650 have a height of 65, and a diameter of ─ 18 mm.

Assessing the characteristics of a particular charger is difficult without understanding how the model charge of a li-ion battery should actually flow. Therefore, before moving directly to the schemes, let's recall a little theory.

What are lithium batteries

Depending on what material the positive electrode of the lithium battery is made of, there are several varieties:

- with a lithium cobaltate cathode;

- with lithiated iron phosphate cathode;

- based on nickel-cobalt aluminum;

- based on nickel-cobalt-manganese.

All these batteries have their own characteristics, but since for the wide consumer these nuances are not of fundamental importance, they will not be considered in this article.

Also, all li-ion batteries are produced in various sizes and form factors. They can be either in the case version (for example, 18650 popular today) or in a laminated or prismatic version (gel-polymer batteries). The latter are hermetically sealed packages from a special film, in which there are electrodes and electrode mass.

The most common sizes of li-ion batteries are shown in the table below (all of them have a nominal voltage of 3.7 volts):

Designation Size Similar size XXYY0,

Where XX - indication of diameter in mm,

Yy - length value in mm,

0 - reflects cylinder design10180 2/5 AAA 10220 1/2 AAA (Ø corresponds to AAA, but half the length) 10280 10430 AAA 10440 AAA 14250 1/2 AA 14270 Ø AA, length CR2 14430 Ø 14 mm (like AA), but shorter 14500 AA 14670 15266, 15270 CR2 16340 CR123 17500 150S / 300S 17670 2xCR123 (or 168S / 600S) 18350 18490 18500 2xCR123 (or 150A / 300P) 18650 2xCR123 (or 168A / 600P) 18700 22650 25500 26500 FROM 26650 32650 33600 D 42120 Internal electrochemical processes proceed in the same way and are independent of the form factor and battery performance, therefore, all that is said below applies equally to all lithium batteries.

How to properly charge lithium-ion batteries

The most correct way to charge lithium batteries is to charge in two stages. It is this method that Sony uses in all of its chargers. Despite the more complex charge controller, this provides a more complete charge of li-ion batteries, without reducing their service life.

Here we are talking about a two-stage charge profile of lithium batteries, abbreviated as CC / CV (constant current, constant voltage). There are still options with pulse and step currents, but they are not considered in this article. Read more about pulse current charging.

So, we consider both stages of the charge in more detail.

1. At the first stage a constant charge current should be provided. The current value is 0.2-0.5C. For an accelerated charge, an increase in current up to 0.5-1.0C is allowed (where C is the battery capacity).

For example, for a battery with a capacity of 3000 mA / h, the nominal charge current in the first stage is 600-1500 mA, and the accelerated charge current can be in the range of 1.5-3A.

To ensure a constant charging current of a given value, the charger circuit must be able to raise the voltage at the battery terminals. In fact, at the first stage, the charger works as a classic current stabilizer.

Important: If you plan to charge batteries with an integrated protection circuit board (PCB), then when designing the memory circuit, you must make sure that the open circuit voltage of the circuit can never exceed 6-7 volts. Otherwise, the protection board may fail.

At the moment when the voltage on the battery rises to 4.2 volts, the battery will gain approximately 70-80% of its capacity (the specific value of the capacity will depend on the charge current: with an accelerated charge it will be slightly less, with a nominal charge a little more). This moment is the end of the first stage of the charge and serves as a signal for the transition to the second (and last) stage.

2. Second stage charge - This is the battery charge with constant voltage, but gradually decreasing (falling) current.

At this stage, the charger maintains a voltage of 4.15-4.25 volts on the battery and controls the current value.

As the capacity gains, the charging current will decrease. As soon as its value decreases to 0.05-0.01С, the charge process is considered completed.

An important nuance of the correct charger is its complete disconnection from the battery after charging. This is due to the fact that for lithium batteries it is extremely undesirable for them to remain under high voltage for a long time, which usually provides a charger (i.e. 4.18-4.24 volts). This leads to accelerated degradation of the chemical composition of the battery and, as a consequence, a decrease in its capacity. A long stay means tens of hours or more.

During the second stage of the charge, the battery manages to gain about 0.1-0.15 more of its capacity. The total battery charge in this way reaches 90-95%, which is an excellent indicator.

We examined two main stages of charge. However, the coverage of lithium battery charging would be incomplete if one more stage of charging were not mentioned - the so-called precharge.

Preliminary charge stage (precharge) - This stage is used only for deeply discharged batteries (below 2.5 V) to bring them to normal operating mode.

At this stage, the charge is provided by a direct current of reduced magnitude until the voltage across the battery reaches 2.8 V.

The preliminary stage is necessary to prevent the accumulators and depressurization (or even explosion with fire) of damaged batteries having, for example, an internal short circuit between the electrodes. If you immediately pass a large charge current through such a battery, this will inevitably lead to its heating, and then how lucky.

Another benefit of pre-charge is pre-heating the battery, which is important when charging at low ambient temperatures (in an unheated room in the cold season).

Intelligent charging should be able to control the voltage on the battery during the preliminary stage of charging and, if the voltage does not rise for a long time, make a conclusion about the battery malfunction.

All stages of the charge of a lithium-ion battery (including the stage of precharge) are schematically depicted in this graph:

Exceeding the nominal charging voltage by 0.15V can halve the battery life. Lowering the charge voltage by 0.1 volts reduces the capacity of a charged battery by about 10%, but significantly extends its service life. The voltage of a fully charged battery after removing it from the charger is 4.1-4.15 volts.

I summarize the above, we outline the main points:

1. What current to charge a li-ion battery (for example, 18650 or any other)?

The current will depend on how quickly you would like to charge it and can range from 0.2C to 1C.

For example, for a standard size 18650 battery with a capacity of 3400 mA / h, the minimum charge current is 680 mA and the maximum is 3400 mA.

2. How long does it take to charge, for example, the same 18650 batteries?

The charge time directly depends on the charge current and is calculated by the formula:

T \u003d C / I charge

For example, the charging time of our 3400 mAh battery with a current of 1A will be about 3.5 hours.

3. How to charge the lithium polymer battery?

Any lithium batteries charge equally. It doesn’t matter whether it is lithium-polymer or lithium-ion. For us consumers, there is no difference.

What is a protection board?

The protection board (or PCB - power control board) is designed to protect against short circuit, overcharge and overdischarge of the lithium battery. As a rule, protection modules also have built-in protection against overheating.

In order to comply with safety precautions, the use of lithium batteries in household appliances is prohibited unless a protection board is built into them. Therefore, all cell phone batteries always have a PCB board. Battery output terminals are located directly on the board:

These boards use a six-legged charge controller on a specialized mikruh (JW01, JW11, K091, G2J, G3J, S8210, S8261, NE57600, etc. analogues). The task of this controller is to disconnect the battery from the load when the battery is completely discharged and to disconnect the battery from charging when it reaches 4.25V.

Here, for example, is a diagram of the BP-6M battery protection board that supplied the old Nokia phones:

If we talk about the 18650, then they can be produced with or without a protection board. The protection module is located in the vicinity of the negative terminal of the battery.

The board increases the battery length by 2-3 mm.

Batteries without a PCB module are usually included in batteries equipped with their own protection circuits.

Any battery with protection easily turns into a battery without protection, just gut it.

To date, the maximum capacity of the 18650 battery is 3400 mA / h. Protected batteries must always be labeled on the case ("Protected").

Do not confuse a PCB board with a PCM module (PCM - power charge module). If the former serve only the purpose of protecting the battery, the latter are designed to control the charge process - they limit the charge current at a given level, control the temperature and, in general, provide the whole process. A PCM board is what we call a charge controller.

I hope now there are no questions left, how to charge the 18650 battery or any other lithium? Then we move on to a small selection of ready-made circuitry solutions for chargers (those same charge controllers).

Li-ion Battery Charging Schemes

All circuits are suitable for charging any lithium battery, it remains only to determine the charging current and the element base.

LM317

Scheme of a simple charger based on the LM317 chip with a charge indicator:

The circuit is simple, the whole setup is reduced to setting the output voltage of 4.2 volts using the tuning resistor R8 (without the battery connected!) And setting the charge current by selecting resistors R4, R6. The power of the resistor R1 is at least 1 Watt.

As soon as the LED goes out, the charging process can be considered completed (the charging current to zero will never decrease). It is not recommended to keep the battery in this charge for a long time after it is fully charged.

The lm317 chip is widely used in various voltage and current stabilizers (depending on the switching circuit). It is sold on every corner and costs a penny in general (you can take 10 pcs for only 55 rubles).

LM317 happens in different cases:

Assignment of conclusions (pinout):

The analogs of the LM317 chip are: GL317, SG31, SG317, UC317T, ECG1900, LM31MDT, SP900, KR142EN12, KR1157EN1 (the last two are of domestic production).

Charging current can be increased to 3A, if instead of LM317 take LM350. True, it will be more expensive - 11 rubles / pc.

The circuit board and circuit assembly are shown below:

The old Soviet transistor KT361 can be replaced with a similar p-n-p transistor (for example, KT3107, KT3108 or bourgeois 2N5086, 2SA733, BC308A). It can be removed altogether if the charge indicator is not needed.

The disadvantage of the circuit: the supply voltage should be between 8-12V. This is due to the fact that for the normal operation of the LM317 chip, the difference between the voltage on the battery and the supply voltage should be at least 4.25 volts. Thus, the USB port will not work.

MAX1555 or MAX1551

The MAX1551 / MAX1555 are specialized chargers for Li + batteries that can run on USB or a separate power adapter (such as a phone charger).

The only difference between these microcircuits - MAX1555 gives a signal for the indicator of the charge process, and MAX1551 - a signal that the power is on. Those. 1555 in most cases is still preferable, so 1551 is now difficult to find on sale.

The only difference between these microcircuits - MAX1555 gives a signal for the indicator of the charge process, and MAX1551 - a signal that the power is on. Those. 1555 in most cases is still preferable, so 1551 is now difficult to find on sale.A detailed description of these chips from the manufacturer.

The maximum input voltage from the DC adapter is 7 V, when powered by USB - 6 V. When the supply voltage drops to 3.52 V, the microcircuit turns off and the charge stops.

The microcircuit itself detects at which input the supply voltage is present and is connected to it. If the power is supplied via the USB bus, then the maximum charge current is limited to 100 mA - this allows you to plug the charger into the USB port of any computer, without fear of burning the south bridge.

When powered by a separate power supply, the typical charge current is 280 mA.

The chips have built-in overheat protection. But even in this case, the circuit continues to work, decreasing the charge current by 17 mA for every degree above 110 ° C.

There is a pre-charge function (see above): as long as the voltage on the battery is below 3V, the microcircuit limits the charge current to 40 mA.

The microcircuit has 5 pins. Here is a typical wiring diagram:

If there is a guarantee that the voltage at the output of your adapter cannot under any circumstances exceed 7 volts, then you can do without the 7805 stabilizer.

The USB charging option can be assembled, for example, on one.

The microcircuit does not need external diodes or external transistors. In general, of course, chic mikruhi! Only they are too small, it is inconvenient to solder. And they are also expensive ().

LP2951

The LP2951 stabilizer is manufactured by National Semiconductors (). It provides the implementation of the built-in current limiting function and allows you to form a stable level of charge voltage of a lithium-ion battery at the circuit output.

The value of the charge voltage is 4.08 - 4.26 volts and is set by the resistor R3 with the battery disconnected. The voltage holds very accurately.

The charge current is 150 - 300mA, this value is limited by the internal circuits of the LP2951 chip (depending on the manufacturer).

Apply a diode with a small reverse current. For example, it can be any one of the 1N400X series that can be acquired. The diode is used as a blocking to prevent reverse current from the battery to the LP2951 chip when the input voltage is turned off.

This charge produces a fairly low charging current, so that some 18650 battery can be charged all night.

The chip can be bought both in the DIP package and in the SOIC package (cost about 10 rubles per item).

MCP73831

The microcircuit allows you to create the right chargers, in addition, it is cheaper than the untwisted MAX1555.

A typical switching circuit is taken from:

An important advantage of the circuit is the absence of low-resistance powerful resistors that limit the charge current. Here, the current is set by a resistor connected to the 5th pin of the microcircuit. Its resistance should lie in the range of 2-10 kOhm.

Charging assembly looks like this:

The microcircuit heats up quite well in the process, but it doesn’t seem to bother her. It performs its function.

Here is another version of the PCB with smd LED and micro-USB connector:

LTC4054 (STC4054)

Very simple scheme, great option! Allows charging with current up to 800 mA (see). True, it tends to heat up very much, but in this case, the built-in overheat protection reduces the current.

The circuit can be greatly simplified by throwing one or even both LEDs with a transistor. Then it will look like this (agree, there’s nowhere simpler: a pair of resistors and one conder):

One PCB option is available at. The board is designed for elements of size 0805.

I \u003d 1000 / R. You should not set up a large current right away, first look at how much the microcircuit will heat up. For my purposes, I took a 2.7 kΩ resistor, while the charge current turned out to be about 360 mA.

It is unlikely that the heatsink can be adapted to this microcircuit, and it is not a fact that it will be effective due to the high thermal resistance of the crystal-case transition. The manufacturer recommends making the heat sink "through the conclusions" - making the tracks as thick as possible and leaving the foil under the chip body. And in general, the more “earthen” foil will be left, the better.

By the way, most of the heat is removed through the 3rd leg, so you can make this track very wide and thick (fill it with excess solder).

The housing of the LTC4054 chip may be labeled LTH7 or LTADY.

LTH7 and LTADY differ in that the first one can raise a strongly run-down battery (on which the voltage is less than 2.9 volts), and the second one cannot (you need to swing it separately).

The microcircuit came out very successful, so it has a bunch of analogues: STC4054, MCP73831, TB4054, QX4054, TP4054, SGM4054, ACE4054, LP4054, U4054, BL4054, WPM4054, IT4504, Y1880, PT6102, PT6181, VS6102, HX6001, LC65050, LC6000160, LC66050, LC6000160 EC49016, CYT5026, Q7051. Before using any of the analogues, check the datasheets.

TP4056

The microcircuit is made in the SOP-8 case (see), it has a metal heat sink on its belly that is not connected to the contacts, which allows more efficient heat dissipation. Allows you to charge the battery with a current of up to 1A (the current depends on the current-setting resistor).

The wiring diagram requires a minimum of attachments:

The circuit implements the classical charge process — first, direct current charge, then constant voltage and incident current. Everything is scientific. If you take apart the charging steps, you can distinguish several stages:

- Monitoring the voltage of the connected battery (this happens all the time).

- Precharge phase (if the battery is discharged below 2.9 V). A charge of 1/10 current from R prog programmed by the resistor (100 mA at R prog \u003d 1.2 kOhm) to the level of 2.9 V.

- Charging with a maximum current of constant value (1000mA at R prog \u003d 1.2 kOhm);

- When the battery reaches 4.2 V, the voltage on the battery is fixed at this level. A gradual decrease in the charging current begins.

- When the current reaches 1/10 of the R prog programmed by the resistor (100 mA at R prog \u003d 1.2 kOhm), the charger is turned off.

- After charging is complete, the controller continues to monitor the battery voltage (see point 1). The current consumed by the monitoring circuit is 2-3 μA. After the voltage drops to 4.0V, charging is turned on again. And so in a circle.

The charge current (in amperes) is calculated by the formula I \u003d 1200 / R prog. Allowed maximum is 1000 mA.

The actual charging test with a 18650 battery at 3400 mAh is shown in the graph:

The advantage of the chip is that the charge current is set by only one resistor. Powerful low impedance resistors are not required. Plus there is an indicator of the charging process, as well as an indication of the end of charging. When the battery is not connected, the indicator blinks once every few seconds.

The supply voltage of the circuit should lie within 4.5 ... 8 volts. The closer to 4.5V, the better (so the chip heats less).

The first leg is used to connect a temperature sensor built into the lithium-ion battery (usually this is the average output of the cell phone’s battery). If the output voltage is below 45% or above 80% of the supply voltage, then charging stops. If you don’t need temperature control, just put that foot on the ground.

Attention! This circuit has one significant drawback: the lack of a battery reversal protection circuit. In this case, the controller is guaranteed to burn out due to exceeding the maximum current. In this case, the supply voltage of the circuit directly hits the battery, which is very dangerous.

The signet is simple, done in an hour on the knee. If time is running out, you can order ready-made modules. Some manufacturers of ready-made modules add protection against overcurrent and overdischarge (for example, you can choose which board you need - with or without protection, and with which connector).

You can also find ready-made boards with a contact for a temperature sensor. Or even a charging module with several parallel TP4056 microcircuits to increase the charging current and with reverse polarity protection (example).

LTC1734

Also a very simple scheme. The charge current is set by the resistor R prog (for example, if you put the resistor at 3 kOhm, the current will be 500 mA).

Chips are usually marked on the case: LTRG (they can often be found in old phones from Samsung).

A transistor is suitable for any p-n-p in general, the main thing is that it is designed for a given charging current.

There is no charge indicator on the indicated circuit, but the LTC1734 says that the “4” (Prog) terminal has two functions - setting the current and monitoring the end of the battery charge. For example, a diagram with the control of the end of charge using the comparator LT1716.

In this case, the comparator LT1716 can be replaced with a cheap LM358.

TL431 + Transistor

It is probably difficult to come up with a scheme of more accessible components. The hardest part is finding the TL431 voltage reference. But they are so common that they are found almost everywhere (rarely, what kind of power source can do without this chip).

Well, the TIP41 transistor can be replaced with any other with a suitable collector current. Even old Soviet KT819, KT805 (or less powerful KT815, KT817) will do.

Setting up the circuit boils down to setting the output voltage (without battery !!!) using a trimming resistor at 4.2 volts. Resistor R1 sets the maximum value of the charging current.

This circuit fully implements the two-stage process of charging lithium batteries - first charging with direct current, then moving to the phase of voltage stabilization and a smooth decrease in current to almost zero. The only drawback is the poor repeatability of the circuit (capricious in tuning and demanding on the components used).

MCP73812

There is another undeservedly neglected microchip from the Microchip company - MCP73812 (see). On its basis, a very low-cost charging option (and inexpensive!) Is obtained. The whole body kit is just one resistor!

By the way, the microcircuit is made in a housing convenient for soldering - SOT23-5.

The only negative is that it gets very hot and there is no charge indication. Still, it somehow does not work very reliably if you have a low-power power source (which gives a voltage drop).

In general, if the charge indication is not important for you, and a current of 500 mA suits you, then the MCP73812 is a very good option.

Ncp1835

A fully integrated solution is proposed - NCP1835B, providing high stability of the charging voltage (4.2 ± 0.05 V).

Perhaps the only drawback of this chip is its too miniature size (DFN-10 case, size 3x3 mm). Not everyone is able to provide high-quality soldering of such miniature elements.

Of the indisputable advantages, I would like to note the following:

- Minimum number of body kit parts.

- Ability to charge a fully discharged battery (30 mA pre-charge);

- Determination of the end of charging.

- Programmable charging current - up to 1000 mA.

- Indication of charge and errors (capable of detecting non-rechargeable batteries and signaling about it).

- Protection against continuous charge (by changing the capacitance C t, you can set the maximum charge time from 6.6 to 784 minutes).

The cost of the chip is not so cheap, but not so high (~ $ 1), to abandon its use. If you are friends with a soldering iron, I would recommend choosing this option.

A more detailed description is in.

Can I charge a lithium-ion battery without a controller?

Yes you can. However, this will require close monitoring of the charging current and voltage.

In general, charging the battery, for example, our 18650 without a charger will not work. All the same, you need to somehow limit the maximum charge current, so at least the most primitive memory, but still be required.

The simplest charger for any lithium battery is a resistor connected in series with the battery:

The resistance and dissipation power of the resistor depend on the voltage of the power source that will be used for charging.

Let's take, as an example, we calculate a resistor for a 5 Volt power supply. We will charge the 18650 battery with a capacity of 2400 mA / h.

So, at the very beginning of charging, the voltage drop across the resistor will be:

U r \u003d 5 - 2.8 \u003d 2.2 Volts

Suppose our 5-volt power supply is rated for a maximum current of 1A. The circuit will consume the largest current at the very beginning of the charge, when the voltage on the battery is minimal and amounts to 2.7-2.8 Volts.

Attention: in these calculations, the probability that the battery can be very deeply discharged and the voltage on it can be much lower, up to zero, is not taken into account.

Thus, the resistance of the resistor necessary to limit the current at the very beginning of the charge at the level of 1 Ampere should be:

R \u003d U / I \u003d 2.2 / 1 \u003d 2.2 Ohms

Dissipation Power Resistor:

P r \u003d I 2 R \u003d 1 * 1 * 2.2 \u003d 2.2 W

At the very end of the battery charge, when the voltage on it approaches 4.2 V, the charge current will be:

I charge \u003d (U un - 4.2) / R \u003d (5 - 4.2) / 2.2 \u003d 0.3 A

That is, as we see, all values \u200b\u200bdo not go beyond the limits acceptable for a given battery: the initial current does not exceed the maximum allowable charge current for a given battery (2.4 A), and the final current exceeds the current at which the battery already ceases to accumulate capacity ( 0.24 A).

The main drawback of such charging is the need to constantly monitor the voltage on the battery. And manually turn off the charge as soon as the voltage reaches 4.2 Volts. The fact is that lithium batteries very poorly tolerate even short-term overvoltage - electrode masses begin to degrade quickly, which inevitably leads to loss of capacity. At the same time, all the prerequisites for overheating and depressurization are created.

If the protection board, which was discussed just above, is built into your battery, then everything is simplified. Upon reaching a certain voltage on the battery, the board itself will disconnect it from the charger. However, this charging method has significant disadvantages, which we talked about in.

The protection built into the battery will not allow it to be recharged under any circumstances. All that remains for you to do is to control the charge current so that it does not exceed the permissible values \u200b\u200bfor this battery (protection boards do not know how to limit the charge current, unfortunately).

Charging with a laboratory power supply

If at your disposal there is a power supply unit with current protection (restriction), then you are saved! Such a power source is already a full-fledged charger that implements the correct charge profile, which we wrote about above (CC / CV).

All you need to do to charge li-ion is to set 4.2 volts on the power supply and set the desired current limit. And you can connect the battery.

Initially, when the battery is still discharged, the laboratory power supply will operate in current protection mode (i.e., it will stabilize the output current at a given level). Then, when the voltage on the bank rises to the set 4.2V, the power supply will go into voltage stabilization mode, and the current will begin to fall.

When the current drops to 0.05-0.1C, the battery can be considered fully charged.

As you can see, the laboratory PSU is an almost perfect charger! The only thing he does not know how to do automatically is to make a decision to fully charge the battery and turn off. But this is a trifle that you should not even pay attention to.

How to charge lithium batteries?

And if we are talking about a disposable battery that is not intended for recharging, then the correct (and only right) answer to this question is NO.

The fact is that any lithium battery (for example, the common CR2032 in the form of a flat tablet) is characterized by the presence of an internal passivating layer with which the lithium anode is coated. This layer prevents the chemical reaction of the anode with electrolyte. And the supply of external current destroys the above protective layer, leading to damage to the battery.

By the way, speaking of the CR2032 non-rechargeable battery, that is, the LIR2032 very similar to it is already a full-fledged battery. It can and should be charged. Only her voltage is not 3, but 3.6V.

We talked about how to charge lithium batteries (be it a phone battery, 18650 or any other li-ion battery) at the beginning of the article.

Where to buy microchips?

You can, of course, buy in Chip-Dip, but it’s expensive there. Therefore, I always take in one very secret store)) The most important thing is to choose the right seller, then the order will come quickly and for sure.

For your convenience, I have collected the most reliable sellers in one table, use your health:

name datasheet price LM317 5.5 rub / pcs Buy LM350 LTC1734 42 rub / pcs. Buy TL431 85 kopecks / pcs. Buy Mcp73812 65 rub / pcs. Buy Ncp1835 83 rub / piece Buy * All chips with free shipping When reading the “operating tips” for batteries on forums, one wonders whether people skipped physics and chemistry at school, or think that the rules for using lead and ion batteries are the same.

Let's start with the principles of the Li-Ion battery. On the fingers, everything is extremely simple - there is a negative electrode (usually made of copper), there is a positive one (made of aluminum), between them there is a porous substance (separator) saturated with electrolyte (it prevents “unauthorized” transition of lithium ions between the electrodes):The principle of operation is based on the ability of lithium ions to integrate into the crystal lattice of various materials - usually graphite or silicon oxide - with the formation of chemical bonds: accordingly, when charging, ions are embedded in the crystal lattice, thereby accumulating charge on one electrode, when discharged, they transfer back to another electrode giving away the electron we need (who are interested in a more accurate explanation of the processes taking place - google intercalation). As the electrolyte, aqueous solutions are used that do not contain a free proton and are stable in a wide voltage range. As you can see in modern batteries, everything is done quite safely - there is no metallic lithium, there is nothing to explode, only ions run along the separator.

Now that everything has become more or less clear with the operating principle, let's move on to the most common myths about Li-Ion batteries:- The first myth. The Li-Ion battery in the device cannot be discharged to zero percent.

In fact, everything sounds right and is consistent with physics - when discharged to ~ 2.5 V, the Li-Ion battery starts to degrade very quickly, and even one such discharge can significantly (up to 10%!) Reduce its capacity. In addition, when discharging to such a voltage with a standard charger, it will not be possible to charge it - if the battery cell voltage drops below ~ 3 V, the "smart" controller will turn it off as damaged, and if such cells are all, the battery can be carried to the trash.

But there is one very important thing that everyone forgets about: in phones, tablets and other mobile devices, the working voltage range on the battery is 3.5-4.2 V. When the voltage drops below 3.5 V, the indicator shows zero percent of the charge and the device turns off, but until critical "2.5 V is still very far away. This is confirmed by the fact that if you connect an LED to such a "discharged" battery, it can light up for a long time (maybe someone remembers that phones with flashlights that were turned on by a button regardless of the system were sold before. So, there the lamp continued to burn even after discharge and turn off the phone). That is, as you can see, with regular use of the discharge, up to 2.5 V does not occur, which means it is quite possible to discharge Akum to zero percent. - The second myth. If Li-Ion is damaged, the batteries explode.

We all remember the “explosive” Samsung Galaxy Note 7. However, this is rather the exception to the rule - yes, lithium is a very active metal, and it is not difficult to detonate it in the air (and it burns very brightly in water). However, modern batteries use not lithium, but its ions, which are much less active. So in order for an explosion to occur, you need to try hard - either damage the charging battery physically (arrange a short circuit), or charge it with a very high voltage (then it will be damaged itself, but most likely the controller will burn down itself and prevent the battery from charging). Therefore, if you suddenly have a damaged or smoking battery in your hands - don’t throw it on the table and run away from the room shouting “we will all die” - just put it in a metal container and take it to the balcony (so as not to breathe chemistry) - the battery will smolder for a while and then go out. The main thing is not to flood with water, the ions are certainly less active than lithium, but still a certain amount of hydrogen will also be released during the reaction with water (and he likes to explode). - The third myth. When the Li-Ion battery reaches 300 (500/700/1000/100500) cycles, it becomes unsafe and needs to be changed urgently.

The myth, fortunately, is walking less and less on forums and having no physical or chemical explanation at all. Yes, during operation, the electrodes are oxidized and corroded, which reduces the battery capacity, but this does not threaten you with anything other than shorter battery life and unstable behavior. - The fourth myth. Li-Ion batteries cannot be used in cold weather.

This is more a recommendation than a ban. Many manufacturers prohibit the use of phones at freezing temperatures, and many have come across a quick discharge and generally disconnecting phones in the cold. The explanation for this is very simple: the electrolyte is a water-containing gel, and everyone knows what happens to water at low temperatures (yes, it freezes if that), thereby taking some area of \u200b\u200bthe battery out of work. This leads to a voltage drop, and the controller begins to consider this a discharge. The battery is not useful, but not fatal (after heating, the capacity will return), so if you desperately need to use the phone in cold weather (use it just out of a warm pocket, look at the time and hide it back) it’s better to charge it 100% and turn on any process that loads the processor - so cooling will occur more slowly. - The fifth myth. A swollen Li-Ion battery is dangerous and needs to be disposed of urgently.

This is not quite a myth, rather a precaution - a swollen battery can burst corny. From a chemical point of view, everything is simple: during the intercalation process, the electrodes and electrolyte decompose, resulting in gas evolution (it can also be released during recharging, but more on that below). But it is allocated very little, and for the battery to seem bloated, several hundred (if not thousands) of recharge cycles (unless of course it is defective) must pass. There are no problems getting rid of the gas - just pierce the valve (in some batteries it opens at excess pressure) and release it (I do not recommend breathing to them), after which you can cover the hole with epoxy. Of course, this battery will not return to its former capacity, but at least now it certainly will not burst. - The sixth myth. Li-ion batteries are harmful overcharge.

But this is no longer a myth, but a harsh reality - when recharging, there is a good chance that the battery will swell, burst and light up - believe me, there is little pleasure in being splattered with boiling electrolyte. Therefore, in all batteries there are controllers that are corny not allowing you to charge the battery above a certain voltage. But here you must be extremely careful in choosing a battery - controllers of Chinese crafts can often fail, and I don’t think you will be happy with the fireworks from the phone at 3 a.m. Of course, the same problem exists in branded batteries, but firstly, this happens much less often, and secondly, the entire phone will be changed under warranty. Usually this myth generates the following: - The seventh myth. Upon reaching 100%, you need to remove the phone from charging.

From the sixth myth, this seems reasonable, but in fact it makes no sense to get up in the middle of the night and remove the device from charging: firstly, controller malfunctions are extremely rare, and secondly, even when reaching 100% on the indicator, the battery is recharged for some time to the very maximum low currents, which adds another 1-3% capacity. So in fact, do not be so reinsured. - Myth eight. You can charge the device only with the original charger.

The myth takes place due to the poor quality of Chinese chargers - at a normal voltage of 5 + - 5% volts, they can give out both 6 and 7 - the controller, of course, will smooth out such voltage for some time, but in the future it will in the best case to the combustion of the controller, at worst - to the explosion and (or) failure of the motherboard. The opposite also happens - under load, the Chinese charger gives out 3-4 volts: this will lead to the fact that the battery will not be able to fully charge.

- unit cell voltage: