Lithium-ion (Li-ion) batteries, used in most modern tablets, smartphones and laptops, require different maintenance and operation rules compared to nickel-cadmium (Ni-Cd) and nickel-metal hydride (Ni-MH) batteries used in earlier devices.

In fact, proper care of a lithium-ion battery can increase its life by 15 times compared with improper use. This article gives tips on how to maximize the life cycle of costly lithium-ion batteries in all of your portable devices.

More recently, Fred Langa, a journalist for the Windows Secrets Internet portal, had to replace a damaged smartphone - and that was his mistake.

The main symptom did not bode well - the phone case was deformed, because the device’s body itself began to bend.

Upon analysis and detailed examination, it turned out that the smartphone’s battery was swollen.

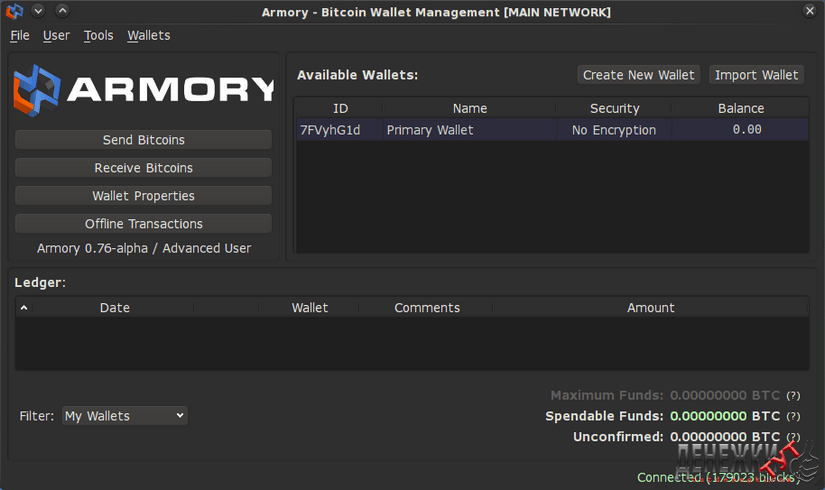

Initially, Fred did not notice any changes: the battery looked more or less normal when viewed from its face (Figure 1). However, when the battery was laid on a flat surface, it became obvious that its upper and lower faces were no longer flat and parallel to each other. A serious bulge formed on one side of the battery (Figure 2). This bulge led to the fact that the phone began to bend and deform.

The bulge of the battery indicated a serious problem: the accumulation of toxic gases under high pressure inside the battery.

The battery case did a great job, but due to toxic gases, the battery was a tiny pressure cooker bomb that was just waiting for detonation.

In the case of Fred, both the phone and the battery were damaged - it is time to buy a new smartphone.

The saddest thing is that this problem could be easily prevented. In the final part of the article, Fred's errors will be given.

In order to avoid repeating the mistakes of the past with the new smartphone and other lithium-ion devices, such as tablets, laptops, Fred began to seriously study the proper operation and maintenance of lithium-ion batteries.

Fred was not interested in issues of extending the work on a single battery charge - these techniques are familiar. Most devices offer manual or automatic power-saving modes and methods for adjusting screen brightness, slowing processor performance, and reducing the number of running applications.

Rather, Fred focused on extending battery life — ways to keep the battery in good working order and extend battery life to the maximum level.

This article includes brief abstracts based on Fred's research. Follow the five suggested tips and then your lithium-ion batteries will work fully, long and safely in all your portable devices.

Tip 1: Monitor the temperature and do not overheat the battery

Surprisingly, heat is one of the main enemies of lithium-ion batteries. The causes of overheating of the battery may be factors of misuse, for example, the speed and duration of the charging and discharging cycles of the battery.

The external physical environment also matters. By simply leaving the device with a lithium-ion battery in the sun or in a closed car, you can significantly reduce the battery’s ability to receive and hold a charge.

Ideal temperature conditions for lithium-ion batteries is a room temperature of 20 degrees Celsius. If the device heats up to 30C, its ability to carry a charge is reduced by 20 percent. If the device is used at 45C, which is easily achievable in the sun or when the device is used intensively by resource-intensive applications, the battery capacity is reduced by about half.

Thus, if your device or battery becomes noticeably warm during use, try moving to a cooler place. If this is not possible, try to reduce the amount of energy consumed by the device by turning off unnecessary applications, services and functions, lowering the screen brightness, or activating the device’s power saving mode.

If this still does not help, completely turn off the device until the temperature returns to normal. For even faster cooling, remove the battery (of course, if the design of the device allows it) - this way the device cools faster due to physical separation from the power source.

By the way, despite the fact that high temperatures are the main problem with lithium-ion batteries, low-temperature operating modes do not cause serious concern. Low temperatures do not cause long-term damage to the battery, although a cold battery will not be able to deliver all the power that it can potentially give out at the optimum temperature. The power drop becomes very noticeable at temperatures below 4C. Most consumer-grade lithium-ion batteries essentially become useless at temperatures near or below freezing.

If a device with a lithium-ion power supply becomes excessively cooled for any reason, do not attempt to use it. Leave it unplugged and transfer it to a warm place (pocket or heated room) until the device reaches its normal temperature. Also, as in the case of overheating, physically remove the battery, and separate heating will speed up the heating process. After the battery warms up to normal temperature, its electrolytic properties will be restored.

Tip 2: Turn off the charger to save battery

Recharge - i.e. connecting the battery to a high voltage power source for too long can also reduce the battery’s ability to hold a charge, shorten its life or what is called “kill on the spot”.

Most consumer-grade lithium-ion batteries are designed to operate at a voltage level of 3.6V per cell, but operate at elevated 4.2V during charging. If the charger delivers excessive voltage for too long, the internal battery may be damaged.

In severe cases, recharging can lead to what engineers call “catastrophic” consequences. Even in moderate cases, the excess heat released during recharging will create a negative temperature effect, described in the first tip.

High-quality chargers can work in concert with the circuitry of modern lithium-ion batteries, reducing the risk of overcharging, reducing the charging current in proportion to the battery charge.

These properties vary significantly depending on the type of technology used in the battery. For example, when using nickel-cadmium (Ni-Cd) and nickel-metal hydride (Ni-MH) batteries, try to leave them connected to the charger for as long as possible. This is due to the fact that older types of batteries have a high level of self-discharge, i.e. they begin to lose a significant amount of stored energy immediately after disconnecting from the charger, even if the portable device itself is disconnected.

In fact, a nickel-cadmium battery can lose up to 10 percent of its charge in the first 24 hours after charging. After this period of time, the self-discharge curve begins to equalize, but the nickel-cadmium battery continues to lose 10-20 percent per month.

The situation with nickel metal hydride batteries is even worse. Their self-discharge rate is 30 percent higher than that of nickel-cadmium colleagues.

However, lithium-ion batteries have a very low self-discharge level. A good working battery will lose only 5 percent of its charge in the first 24 hours after charging and another 2 percent in the first month after that.

Thus, there is no need to leave the device with a lithium-ion battery connected to the charger until the last moment. For best results and extend battery life, unplug the charger when the full charge is shown.

New devices with lithium-ion batteries do not need to be charged continuously before first use (in devices with nickel-cadmium and nickel-metal hydride batteries, charging from 8 to 24 hours is recommended). Lithium-ion batteries are maximally charged when they show a 100 percent charge. Advanced charging is not necessary.

Not all discharge cycles affect battery condition in the same way. Prolonged and intensive use generates more heat, seriously loading the battery, and shorter, more frequent discharge cycles, on the contrary, extend the battery life.

You might think that increased cycles of small discharge / charge can seriously reduce the life of the power source. This was only natural for outdated technologies, but does not apply to modern lithium-ion batteries.

Battery specifications can be misleading since many manufacturers see the charge cycle as the time it takes to reach a 100 percent charge level. For example, two charges from 50 to 100 percent are equivalent to one full charge cycle. Similarly, three cycles of 33 percent or 5 cycles of 20 percent are also equivalent to one full cycle.

In short, a large number of small charge-discharge cycles do not reduce the total volume of cycles for a full charge of a lithium battery.

Again, heat and high load from heavy discharges reduce battery life. Therefore, try to reduce the number of deep discharges to a minimum. Do not let the battery level drop to values \u200b\u200bclose to zero (when the device itself turns off). Instead, consider the lower 15-20 percent of the battery charge as an emergency reserve - only in extreme cases. Get used to replacing the battery, if possible, or connecting the device to an external power source before the battery is completely discharged.

As you know, fast discharge and fast charging are accompanied by the release of excess heat and adversely affect the battery life.

If you have used the device intensively under heavy loads, allow the batteries to cool to room temperature before connecting to the charger. The battery will not be able to accept a full charge when heated.

While charging the device, monitor the temperature of the battery - it should not be too hot. A hot battery during charging usually indicates that too much current is flowing quickly.

Recharging is most likely with cheap unbranded chargers using fast charging circuits or with wireless (inductive) chargers.

A cheap charger can be an ordinary transformer with wires connected to it. Such “dumb charges" simply distribute the current and practically do not receive feedback from the charged device. Overheating and overvoltage are very common when using such chargers, which slowly destroys the battery.

“Quick” charges are designed to provide a minute charge, rather than a long hour charge. There are various approaches to fast charge technology, and not all of them are compatible with lithium-ion batteries. If the charger and battery are not designed to work together, fast charging can cause overvoltage and overheating. Generally speaking, it is better not to use a charger of one brand to charge a portable device of another brand.

Wireless (inductive) chargers use a special charging surface to restore battery power. At first glance, this is very convenient, but the fact is that such charges emit excess heat even in normal operation (Some stoves use the phenomenon of induction to heat pots and pans).

Lithium batteries not only experience a negative factor in the form of heat, but also spend energy while charging using wireless technology. By nature, the efficiency of an inductive charger is always lower than a conventional counterpart. Here everyone is free to make a choice on their own, but for Fred, increased heat and lower efficiency are sufficient factors to refuse such devices.

In any case, the safest approach is to use the supplied charger recommended by the manufacturer. This is the only guaranteed way to keep temperature and voltage within normal limits.

If it is not possible to use an OEM charger, use a device with a low output current to reduce the likelihood of battery damage due to the rapid arrival of high power.

One of the low output current power supplies is the USB port on a regular computer. The standard USB 2.0 port provides a current of 500mA (0.5A) per port, while USB 3.0 provides 900mA (0.9A) per port, respectively. For comparison, some special chargers can give out 3000-4000mA (3-4A). The low amperage of the USB ports generally guarantees safe charging with normal temperature conditions for most modern lithium-ion batteries.

Tip 5: If possible, use a spare battery

If your device allows you to quickly replace the battery, having a spare battery is great insurance. This not only doubles the operating time of the device, but also eliminates the need for a full battery discharge or the use of a quick charge. When the battery charge reaches 15-20 percent, just change the discharged battery to a spare one and you will instantly get a full charge of the device without any problems with overheating.

A spare battery has other advantages. For example, if you find yourself in a situation where the installed battery has overheated (for example, due to the intensive operation of the device or because of the high ambient temperature), you can change the hot battery to cool it faster and still use the device.

The presence of two batteries eliminates the need to use a fast charge - you can safely use the device when the battery is slowly charging from a safe power source.

Fred's Fatal Mistakes

Fred suggested that he might damage the smartphone’s battery while traveling. He used the GPS function in the device to navigate during a clear sunny day. The smartphone was in the sun for a long time in the holder in the area of \u200b\u200bthe car dashboard, the brightness of the smartphone was turned on to the maximum in order to distinguish the card from bright sunlight.

In addition, all standard background applications are email, instant messenger, etc. were launched. The device used a 4G module to download music tracks and a Bluetoorth wireless module to transfer sound to the car’s head sound device. The phone definitely worked under stress.

In order for the phone to receive power, it was connected to a 12V adapter, bought according to the criteria of a low price and the presence of the correct connector.

The combination of direct sunlight, high processor load, turned on at maximum screen brightness and dubious adapter quality, led to excessive overheating of the smartphone. Fred recalls with horror how hot the device was when pulled out of the holder. This severe overheating just became the catalyst for the death of the battery.

Apparently, the problem was aggravated at night, when Fred left the device connected to the network all night using a third-party charger, while not monitoring the moment the battery was fully charged.

With his new smartphone, Fred will only use an integrated charger and a spare battery. Fred hopes for a long and safe period of operation of both the battery and the phone, which he is going to achieve with the help of these tips.

Found a typo? Press Ctrl + Enter

- Transfer

Battery death: we all saw how this happens. On phones, laptops, cameras, and now electric cars, the process is painful and - if you're lucky - slow. Over the years, the lithium-ion battery that once powered your devices for several hours (and even days!) Gradually loses its ability to hold a charge. In the end, you will reconcile, perhaps curse Steve Jobs, and then buy a new battery, or even a new gadget.

But why is this happening? What happens in a battery that makes it give off a breath? The short answer is that due to damage from prolonged exposure to high temperatures and a large number of charge and discharge cycles, the process of moving lithium ions between the electrodes eventually begins to be disrupted.

A more detailed answer, which will lead us through a description of undesirable chemical reactions, corrosion, the threat of high temperatures and other factors affecting performance, begins with an explanation of what happens in lithium-ion batteries when everything works well.

Introduction to lithium-ion batteries

In a conventional lithium-ion battery, we will find a cathode (or negative electrode) made of lithium oxides, such as lithium oxide with cobalt. We will also find an anode or a positive electrode, which today is usually made of graphite. A thin porous separator holds two electrodes apart to prevent short circuits. And an electrolyte made from organic solvents and based on lithium salts, which allows lithium ions to move inside the cell.

In a conventional lithium-ion battery, we will find a cathode (or negative electrode) made of lithium oxides, such as lithium oxide with cobalt. We will also find an anode or a positive electrode, which today is usually made of graphite. A thin porous separator holds two electrodes apart to prevent short circuits. And an electrolyte made from organic solvents and based on lithium salts, which allows lithium ions to move inside the cell. During charging, an electric current moves lithium ions from the cathode to the anode. During discharge (in other words, when using the battery), the ions move back to the cathode.

Daniel Abraham, a scientist from the Argonne National Laboratory, conducting research on the degradation of lithium-ion cells, compared this process with water in a hydropower system. Moving up water requires energy, but it flows very easily down. In fact, it supplies kinetic energy, says Abraham, similarly, the lithium-cobalt oxide in the cathode “doesn't want to give up its lithium.” Like water moving upward, energy is needed to move lithium atoms from the oxide and move them to the anode.

During charging, ions are placed between the sheets of graphite that make up the anode. But, as Abraham put it, “they don’t want to be there, as soon as possible they will move back” as water flows down the hill. This is discharge. The long-lived battery can withstand several thousand such charge-discharge cycles.

When is a dead battery really dead?

When we talk about a “dead” battery, it’s important to understand two performance metrics: energy and power. In some cases, the speed with which you can receive energy from the battery is very important. This is power. In electric vehicles, high power makes possible fast acceleration, as well as braking, in which the battery needs to be charged within a few seconds.

When we talk about a “dead” battery, it’s important to understand two performance metrics: energy and power. In some cases, the speed with which you can receive energy from the battery is very important. This is power. In electric vehicles, high power makes possible fast acceleration, as well as braking, in which the battery needs to be charged within a few seconds. In cell phones, on the other hand, high power is less important than capacity, or the amount of energy a battery can hold. High capacity batteries last longer on a single charge.

Over time, the battery degrades in several ways, which can affect both capacity and power, until, in the end, it simply can not perform the basic functions.

Think about it in another analogy related to water: charging the battery, like filling a bucket with tap water. Bucket capacity is the capacity of the battery, or capacity. The speed with which you can fill it - turning the crane at full power or in a thin stream - this is power. But time, high temperatures, multiple cycles and other factors ultimately form a hole in the bucket.

In analogy with a bucket, water seeps out. In a battery, lithium ions are removed, or “attached,” says Abraham. As a result, they lose the ability to move between the electrodes. Therefore, after several months, the mobile phone, which initially required charging once every couple of days, now needs to be charged every day. Then twice a day. In the end, too many lithium ions will “bind”, and the battery will not hold any useful charge. The bucket will stop holding water.

What breaks and why

The active part of the cathode (the source of lithium ions in the battery) is designed with a specific atomic structure to ensure stability and performance. When the ions move to the anode and then return to the cathode back, ideally, they would like to return to their original location in order to maintain a stable crystalline structure.

The active part of the cathode (the source of lithium ions in the battery) is designed with a specific atomic structure to ensure stability and performance. When the ions move to the anode and then return to the cathode back, ideally, they would like to return to their original location in order to maintain a stable crystalline structure. The problem is that the crystal structure can change with each charge and discharge. The ions from apartment A will not necessarily return home, but can move into apartment B in the neighborhood. Then the ion from apartment B finds its place occupied by this tramp and, without entering into confrontation, decides to settle down the corridor. And so on.

Gradually, these "phase transitions" in the material transform the cathode into a new crystalline structure of a crystal with other electrochemical properties. The exact arrangement of atoms, initially providing the necessary performance, is changing.

In hybrid car batteries, which are only needed to supply power when the vehicle accelerates or slows down, said Abraham, these structural changes are much slower than in electric vehicles. This is due to the fact that in each cycle in the system only a small fraction of lithium ions moves. As a result, it is easier for them to return to their original positions.

Corrosion problem

Degradation may also occur in other parts of the battery. Each electrode is connected to a current collector, which is essentially a piece of metal (usually copper for the anode, aluminum for the cathode), which collects electrons and moves them to an external circuit. So, we have clay from such an “active” material as lithium-cobalt oxide (which is ceramic and is not a very good conductor), as well as a glue-like binder material deposited on a piece of metal.

Degradation may also occur in other parts of the battery. Each electrode is connected to a current collector, which is essentially a piece of metal (usually copper for the anode, aluminum for the cathode), which collects electrons and moves them to an external circuit. So, we have clay from such an “active” material as lithium-cobalt oxide (which is ceramic and is not a very good conductor), as well as a glue-like binder material deposited on a piece of metal. If the binder material is destroyed, this leads to "peeling" of the surface of the current collector. If a metal corrodes, it cannot move electrons efficiently.

Corrosion in the battery can occur as a result of the interaction of electrolyte and electrodes. The graphite anode is “easy to discharge”, i.e. he easily "gives" electrons to the electrolyte. This can lead to unwanted coatings on the surface of graphite. The cathode, meanwhile, is very “oxidizable,” which means it easily accepts electrons from the electrolyte, which in some cases can corrode the aluminum of the current collector or form a coating on parts of the cathode, says Abraham.

Too much good

Graphite, a material widely used to make anodes, is thermodynamically unstable in organic electrolytes. This means that from the very first charge of our battery, graphite reacts with electrolyte. This creates a porous layer (called a solid electrolyte interface or TEI), which ultimately protects the anode from further attacks. This reaction also consumes a small amount of lithium. In an ideal world, this reaction would occur once to create a protective layer, and that would be it.

Graphite, a material widely used to make anodes, is thermodynamically unstable in organic electrolytes. This means that from the very first charge of our battery, graphite reacts with electrolyte. This creates a porous layer (called a solid electrolyte interface or TEI), which ultimately protects the anode from further attacks. This reaction also consumes a small amount of lithium. In an ideal world, this reaction would occur once to create a protective layer, and that would be it. In reality, however, TEI is a very unstable advocate. It protects graphite well at room temperature, says Abraham, but at high temperatures or when the battery charge drops to zero (“deep discharge”), TEI can partially dissolve in the electrolyte. At high temperatures, electrolytes also tend to decompose and adverse reactions accelerate.

When the favorable conditions return, another protective layer will form, but this will eat some of the lithium, leading to the same problems as a leaky bucket. We will have to charge our cell phone more often.

So, we need a TEI to protect the graphite anode, and in this case there can really be too much good. If the protective layer is too thick, it becomes a barrier to lithium ions, from which it is required to freely move back and forth. This affects power, which, as Abraham emphasizes, is “extremely important” for electric vehicles.

Creating Better Batteries

So what can be done to extend the life of our batteries? Researchers in laboratories are looking for electrolytic supplements that would function like vitamins in our diet, i.e. will allow batteries to work better and live longer by reducing harmful reactions between the electrodes and the electrolyte, says Abraham. In addition, they are looking for new, more stable crystalline structures for electrodes, as well as more stable binders and electrolytes.

So what can be done to extend the life of our batteries? Researchers in laboratories are looking for electrolytic supplements that would function like vitamins in our diet, i.e. will allow batteries to work better and live longer by reducing harmful reactions between the electrodes and the electrolyte, says Abraham. In addition, they are looking for new, more stable crystalline structures for electrodes, as well as more stable binders and electrolytes. Meanwhile, engineers at battery and electric car companies are working on housings and thermal management systems in an attempt to keep lithium-ion batteries in a constant, healthy temperature range. As consumers, it remains for us to avoid extreme temperatures and deep discharge, and also to continue to grumble about batteries that seem to always die too quickly.

The consumer market for lithium-ion (Li-ion) batteries is huge - about $ 10 billion, while it is quite stable, the growth rate is only 2% per year. But what about electric cars, you ask? Indeed, in the coming years, due to the development of electric vehicles, the annual growth rate of lithium-ion batteries is projected at 10%. Surprisingly, the biggest growth area of \u200b\u200bthe Li-ion battery market is still “everything else”, from mobile phones to forklifts.

The “other” applications for lithium-ion batteries typically have one thing in common - these are devices that are powered by sealed lead-acid batteries (SLA). Over the past nearly 200 years, lead-acid batteries have taken a leading position in the electronics market, but they have been superseded by lithium-ion batteries for several years now. Since in many cases lithium-ion batteries began to replace lead-acid batteries (batteries), it is worth comparing these two types of energy storage devices, emphasizing the main technical features and the economic feasibility of using Li-ion instead of traditional SLA devices.

Battery History

The lead acid battery is the first rechargeable battery designed for commercial use in the 1850s. Despite a rather decent age of more than 150 years, they are still actively used in modern devices. Moreover, they are actively used in applications where, it would seem, it is quite possible to get by with modern technologies. Some common devices are actively using SKB, such as uninterruptible power supplies (UPS), golf carts or forklifts. Surprisingly, the lead-acid battery market is still growing for certain niches and projects.

The first, quite tangible innovation in lead-acid technology came in the 1970s, when sealed SKBs or maintenance-free SKBs were invented. This modernization consisted in the appearance of special valves for bleeding gases when charging / discharging batteries. In addition, the use of a humidified separator made it possible to operate the battery in an inclined position without leaking electrolyte.

SKB, or English. SLAs are often classified by type or application. Two types are currently the most common: gel, also known as a valve-regulated lead acid (VRLA), and absorbent glass mat AGM. AGM batteries are used for small UPSs, emergency lighting and wheelchairs, while VRLA is intended for larger applications such as backup power for cellular relay masts, Internet centers and forklifts. Lead-acid batteries can also be classified according to the following criteria: automotive (starter or SLI - start, lighting, ignition); traction (traction or deep cycle); stationary (uninterruptible power supplies). The main drawback of SLA in all these applications is the life cycle - if they are repeatedly discharged, they are badly damaged.

Surprisingly, lead-acid batteries have been the undisputed market leaders in batteries for decades, until the advent of lithium-ion batteries in the 1980s. A lithium-ion battery is a rechargeable cell in which lithium ions move from a negative electrode to a positive one during a discharge and vice versa during a charge. Lithium-ion batteries use intercalated lithium compounds, but do not contain lithium metal, which is used in disposable batteries.

A lithium-ion battery was first invented in the 1970s. In the 1980s, the first commercial version of a cobalt oxide cathode battery was introduced to the market. This type of device had significantly greater capabilities in weight and capacity compared to nickel-based systems. New lithium-ion batteries have contributed to the huge growth in the mobile phone and laptop market. Initially, for safety reasons, safer options were introduced that included nickel and manganese-based additives in the cobalt oxide cathode material, in addition to innovations in cell construction.

The first lithium-ion cells on the market were in rigid aluminum or steel cans, and, as a rule, had only a few cylindrical or prismatic (brick shape) form factors. However, with the expansion of the range of applications of lithium-ion technology, their overall dimensions began to change.

For example, less expensive versions of older technology are used in laptops and cell phones. Modern thin lithium-polymer elements are used in smartphones, tablets and wearable devices. Currently, lithium-ion batteries are used in power tools, electric bicycles and other devices. This variation portends a complete replacement of lead-acid devices in more and more new applications aimed at improving overall and power indicators.

Chemical features

The fundamental foundations of chemical processes in cells give certain properties and varying degrees of functionality to lead-acid and lithium-ion devices. Below are some of the advantages of lead-acid batteries, which have made it the main one for decades and the disadvantages that now lead to its replacement, as well as similar aspects for lithium-ion devices.

Lead acid battery

- SKB is simple, reliable and inexpensive. It can be used in a wide temperature range.

- Batteries must be stored in a continuously charged state (SoC) and they cannot be charged quickly.

- SKB are heavy. Their gravimetric energy density is very low.

- The life cycle usually ranges from 200 to 300 discharges / charges, which is very small.

- The charge / discharge curve allows SOC measurements with simple voltage control.

Lithium ion battery

- They have maximum energy density in size and weight.

- The life cycle usually ranges from 300 to 500, but can be measured in the thousands for lithium phosphate cells;

- The operating temperature range is very small;

- Various cell sizes, shapes and other features are available;

- No maintenance needed. The level of self-discharge is very small.

- Implementation of operational safety schemes is required. Sophisticated charging algorithm.

- SoC measurements require complex solutions due to the non-linearity of the voltage curve.

Electronics

It is important to understand the difference between the battery pack and the battery. A cell is the main component of a package. In addition, the package also includes electronics, connectors and housing. The figure above shows examples of these devices. A lithium-ion rechargeable battery must have at least implemented protection and control circuits for the cell, and a charger and a voltage measurement system are much more complicated than in lead-acid devices.

When using lithium-ion and lead-acid batteries, the main differences in electronics will be as follows:

Charging

Charging a lead-acid battery is quite simple when certain voltage thresholds are met. Lithium-ion batteries use a more sophisticated algorithm, with the exception of iron phosphate-based packets. The standard charging method for such devices is the DC / DC method (CC / CV). It includes a two-stage charging process. At the first stage, a direct current charge occurs. This lasts until the voltage on the cell reaches a certain threshold, after which the voltage remains constant, and the current decreases exponentially until it reaches the cutoff value.

Charge Count and Communication

As mentioned earlier, the SCB charge can be measured by simple means of measuring voltage. When using lithium-ion batteries, it is necessary to control the cell charge level, which requires the implementation of complex algorithms and training cycles.

I 2 C is the most common and economical communication protocol used in lithium-ion batteries, but it has limitations in terms of noise immunity, signal integrity over distance, and overall bandwidth. The SMBus (system control bus), a derivative of I 2 C, is very common in smaller batteries, but does not currently have any effective support for larger or larger packages. CAN is perfect for environments with high noise levels or where long runs are required, such as in many SKB applications, but it is quite expensive.

Direct replacements

It should be emphasized that there are now several standard formats for lead-acid batteries. For example, U1, a standard form factor used in backup applications for medical equipment. The lithium-iron-phosphate battery turned out to be a worthy replacement for lead-acid. Iron phosphate has a remarkable life cycle, good charge conductivity, improved safety and low impedance. The voltages of lithium-iron-phosphate batteries also agree well with the voltages of lead-acid (12 V and 24 V), which makes it possible to use the same chargers. Software packages for battery maintenance and monitoring include intelligent features such as charge tracking, charge / discharge cycle counter, and others.

Lithium iron phosphate batteries retain 100% capacity during storage, unlike SKB batteries that lose capacity over several months of storage. The figure above compares two products and the types of achievements achieved in the transition from SKB to Li-ion.

findings

There are very few batteries that can store as much energy as lead-acid, which makes this type of battery economically viable for many powerful devices. Lithium-ion technology is constantly decreasing in price, and the constant improvement of their chemical structures and safety systems makes them a worthy competitor to lead-acid technology. Devices for their use can be very different, ranging from uninterruptible power supplies, to electric vehicles and drones.

Today, special batteries are used for mobile, household appliances and tools. They differ in operational characteristics. In order for the battery to work for a long time, without failures, the requirements of the manufacturers of the products presented must be taken into account.

One of the most popular types today are Li-Ion batteries. How to properly charge this type of battery, as well as the features of its operation should be considered in detail before operating the device.

general characteristics

One of the most common types of batteries today is the Li-Ion type. Such devices have a relatively low cost. However, they are undemanding to operating conditions. In this case, the user rarely raises the question of how to properly charge a cylindrical Li-Ion 18650 battery or another variety.

Most often, the presented batteries are installed in smartphones, laptops, tablets and other similar devices. The presented batteries are characterized by durability and reliability. They are not afraid of complete discharge.

One of the main features of the presented products is the absence of a “memory effect". These batteries can be charged at almost any convenient time. A “memory effect" occurs when the battery is not fully discharged. If a small amount of charge remains in it, over time, the battery capacity will begin to decline. This will lead to insufficient power supply of the equipment. In lithium-ion batteries, the “memory effect" is minimized.

Design

The design of the lithium-ion battery depends on the type of device for which it is intended. A battery called a “bank” is used for a mobile phone. It has a rectangular shape and includes one structural element. Its rated voltage is 3.7 V.

The battery of the presented type for a laptop has a completely different design. There can be several separate battery cells in it (2-12 pieces). Each of them has a cylindrical shape. These are Li-Ion 18650 batteries. How to charge them properly is indicated in detail by the manufacturer of the equipment. This design incorporates a special controller. It looks like a microchip. The controller controls the charging procedure, does not allow exceeding the nominal value of the battery capacity.

Modern batteries for tablets and smartphones also include a charge control function. This significantly extends battery life. It is protected from various adverse factors.

Charging Features

Considering how to properly charge the Li-Ion batteries of a phone, laptop and other equipment, you need to pay attention to the features of the presented device. It should be said that lithium-ion batteries do not tolerate deep discharge and overcharge. This is controlled by a special device that is added to the design (controller).

It is ideal to maintain the charge of the type of battery presented at a level of 20 to 80% of full capacity. This is monitored by the controller. However, experts do not recommend leaving the device connected to charging constantly. This significantly reduces battery life. In this case, a constant load acts on the controller. Over time, its functionality may decrease due to this.

In this case, the controller also will not allow deep discharge. He just disconnects the battery at some point. This protective function is essential. Otherwise, the user could accidentally recharge or discharge the battery too much. Also in modern-style batteries, high-quality protection against overheating is provided.

Battery Principle

To understand how to properly charge a Li-Ion battery (new or used), you need to consider the principle of its operation. This will assess the need to control the level of discharge and charge of the device.

Lithium ions in the battery of the present type move from one electrode to another. In this case, an electric current appears. Electrodes can be made of different materials. This indicator to a lesser extent affects the operational characteristics of the device.

Lithium ions grow on the crystal lattice of electrodes. The latter, in turn, change their volume and composition. When the battery is charged or discharged, it becomes larger on one of the electrodes. The higher the load on the metal structural elements that lithium exerts, the shorter the life of the device will be. Therefore, it is better not to allow a high percentage of ion deposition on one or the other electrode.

Charging options

Before using the battery, you need to consider how to properly charge the Li-Ion battery of a smartphone, tablet and other equipment. There are several ways to do this.

One of the most correct decisions will be the use of a charger. It is supplied with every manufacturer by electronic equipment.

The second option is to charge the battery from a desktop computer connected to a household network. A USB cable is used for this. In this case, the charging procedure will be longer than when using the first method.

You can perform this procedure using the cigarette lighter in the car. Another less popular way is to charge a lithium-ion battery using a universal device. It is also called the "frog." Most often, such devices are used to recharge the batteries of smartphones. The contacts of this device can be adjusted in width.

Charge a new battery

The new battery must be put into operation correctly. To do this, the phone, tablet or other equipment must be completely discharged. Only when the device turns off can it be connected to the network. The controller will not allow the battery to discharge too much. It is he who turns off the device when the battery loses capacity to a predetermined level.

Next, you need to connect electrical equipment to the network using a standard charger. The procedure is performed until the indicator lights up in green. You can leave the device on the network for a few more hours. This procedure is carried out several times. In this case, you do not need to specifically discharge the phone, tablet or laptop.

Normal charge

Knowing how to properly charge Li-Ion batteries can significantly extend the battery life. Experts recommend the correct procedure for this process for a new battery. After that, it is not advisable to discharge the battery completely. When the indicator shows that the battery capacity has a charge of only 14-15%, it must be connected to the network.

At the same time, it is also not recommended to use other devices to fill the battery capacity, except for the regular one. It has the most acceptable current ratings available for a specific battery model. Other options can be used only in case of emergency.

Calibration

There is one more nuance that you need to learn when studying the question of how to properly charge Li-Ion batteries. Experts recommend periodically calibrating this device. It is held every three months.

First, in normal mode, you need to discharge the electrical equipment before it turns off. Then it is connected to the network. Charging continues until the indicator lights up green (battery is 100% charged). This procedure must be performed for the controller to work properly.

In such a procedure, the battery circuit board determines the limits for charging and discharging. This is necessary to ensure the normal operation of the controller, avoiding failures. In this case, a standard charger is used, which is supplied by the manufacturer complete with a phone, tablet or laptop.

Storage

In order for the battery to work as long and efficiently as possible, you must also consider how to properly charge the Li-Ion battery for storage. In some cases, a situation may arise when the device for powering equipment is temporarily not in use. In this case, it must be properly prepared for storage.

The battery is charged up to 50%. In this state, it can be stored for a long time. However, the ambient temperature should be about 15 ºС. If it increases, the rate of loss of battery capacity will increase.

If the battery needs to be stored for a sufficiently long time, it needs to be completely discharged and charged once a month. The battery gains 100% of its predetermined capacity. Then the device is discharged again and charged up to 50%. If you regularly perform this procedure, you can store the battery for a very long time. After that, it will be fully operational.

Having considered how to properly charge Li-Ion batteries, you can significantly extend the life of this type of battery.

Operation, charging, pros and cons of lithium batteries

Many people today use electronic devices in their daily lives. Cell phones, tablets, laptops ... Everyone knows what it is. But few know that a lithium battery is a key element of these devices. This type of battery packs almost every mobile device. Today we’ll talk about lithium batteries. These batteries and their production technology are constantly evolving. A significant update of the technology occurs every 1–2 years. We will look at the general principle of lithium batteries, and separate materials will be devoted to varieties. Below will be considered the history of occurrence, operation, storage, advantages and disadvantages of lithium batteries.

Research in this direction was carried out at the beginning of the 20th century. “First Swallows” in the lithium battery family appeared in the early seventies of the last century. The anode of these batteries was made of lithium. They quickly became in demand due to the fact that they had high specific energy. Due to the presence of lithium, a very active reducing agent, the developers were able to greatly increase the nominal voltage and specific energy of the element. The development, subsequent testing and refinement of the technology “to mind” took about two decades.

During this time, mainly issues were solved with the safety of using lithium batteries, the selection of materials, etc. Secondary lithium cells with aprotic electrolytes and the solid cathode variety are similar in electrochemical processes that occur in them. In particular, anode dissolution of lithium occurs on the negative electrode. Lithium is being introduced into the crystal lattice of the positive electrode. When the battery cell is charging, the processes on the electrodes go in the opposite direction.

Materials for the positive electrode developed quickly enough. The main requirement for them was that they undergo reversible processes.

We are talking about anodic extraction and cathodic implantation. These processes are also called anodic deintercalation and cathodic intercalation. Researchers tested various materials as a cathode.

The requirement was that there be no change during cycling. In particular, materials such as:

- TiS2 (titanium disulfide);

- Nb (Se) n (niobium selenide);

- vanadium sulfides and dyslenides;

- sulfides of copper and iron.

All of these materials have a layered structure. Studies were also conducted with materials of more complex compositions. For this, additives of some metals in small quantities were used. These were elements with cations of a larger radius than Li.

High specific characteristics of the cathode were obtained on metal oxides. Various oxides were tested for reversible work, which depends on the degree of distortion of the crystal lattice of the oxide material when lithium cations are introduced there. The electronic conductivity of the cathode was also taken into account. The task was to ensure that the cathode volume changes no more than 20 percent. According to studies, vanadium and molybdenum oxides showed the best results.

With the anode, the main difficulties arose when creating lithium batteries. More precisely, during charging, when cathodic deposition of Li occurs. In this case, a surface with a very high activity is formed. Lithium is deposited on the cathode surface in the form of dendrites and as a result a passive film is formed.

It turns out that this film envelops lithium particles and prevents their contact with the base. This process is called encapsulation and leads to the fact that after charging the battery a certain part of lithium is excluded from electrochemical processes.

As a result, after a certain number of cycles, the electrodes wore out and the temperature stability of the processes inside the lithium battery was violated.

At some point, the element warmed up to the melting point of Li and the reaction passed into an uncontrolled phase. So, in the early 90s, many lithium batteries were returned to the enterprises of the companies involved in their production. These were one of the first batteries that were used in mobile phones. At the time of the conversation (the current reaches its maximum value), a flame was emitted from these batteries over the telephone. There were many cases when the user was burned face. The formation of dendrites during the deposition of lithium, in addition to the danger of fire and explosion, can lead to a short circuit.

Therefore, the researchers spent a lot of time and effort developing a cathode by processing the surface. Methods were developed for introducing additives to the electrolyte that prevent the formation of dendrites. In this direction, scientists have achieved success, but the problem has not yet been completely resolved. They tried to solve these problems using metallic lithium by another method.

So, the negative electrode began to be made from lithium alloys, and not from pure Li. The most successful was the alloy of lithium and aluminum. When the discharge process is in progress, then lithium is etched from the alloy in the electrode, and vice versa when charged. That is, during the charge-discharge cycle, the concentration of Li in the alloy changes. Of course, there has been some loss of lithium activity in the alloy compared to metallic Li.

The potential of the alloy electrode decreased by about 0.2-0.4 volts. The operating voltage of the lithium battery decreased and at the same time the interaction of the electrolyte and the alloy decreased. This has become a positive factor, since self-discharge has decreased. But the alloy of lithium and aluminum is not widespread. The problem here was that the specific volume of this alloy changed greatly during cycling. When a deep discharge occurred, the electrode was embrittled and crumbled. Due to a decrease in the specific characteristics of the alloy, studies in this direction were discontinued. Other alloys were also studied.

Studies have shown that Li alloys with heavy metals are best suited. An example is Wood's alloy. They showed themselves well in terms of maintaining the specific volume, but the specific characteristics were insufficient for use in lithium batteries.

As a result, due to the fact that metallic lithium is unstable, research began to be conducted in a different direction. It was decided to exclude pure lithium from the battery components, and to use its ions. So there were lithium ion (Li-Ion) batteries.

The energy density of lithium-ion batteries is lower than that of lithium. But their safety and ease of use are much higher. You can read more about this link.

Operation and Life

Exploitation

The operating rules will be considered on the example of common lithium batteries that are used in mobile devices (phones, tablets, laptops). In most cases, these batteries are protected from the "fool" by the built-in controller. But it is useful for the user to know basic things about the device, parameters and operation of lithium batteries.

To begin with, you should remember that a lithium battery must have a voltage of 2.7 to 4.2 volts. The lower value here indicates the minimum charge level, the upper - the maximum. In modern Li batteries, the electrodes are made of graphite and in their case the lower voltage limit is 3 volts (2.7 is the value for coke electrodes). The electric energy that the battery gives off when the voltage drops from the upper boundary to the lower is called its capacity.

To extend the life of lithium batteries, manufacturers narrow the voltage range somewhat. Often it is 3.3–4.1 volts. As practice shows, the maximum service life of lithium batteries is achieved at a charge level of 45 percent. If the battery is overexposed on charging or is very discharged, the service life is reduced. It is usually recommended to put a lithium battery in charge at 15–20% of the charge. And stop charging immediately after reaching 100% capacity.

But, as already mentioned, the battery saves its controller from overcharging and deep discharge. This control board with a chip is available on almost all lithium batteries. In various consumer electronics (tablet, smartphone, laptop), the operation of the controller integrated into the battery is additionally supplemented by a microcircuit that is soldered to the board of the device itself.

In general, the correct operation of lithium batteries is ensured by their controller. The user is mainly required not to get stuck in this process and not engage in amateur activities.

Life time

The life of lithium batteries is about 500 charge-discharge cycles. This value is true for most modern lithium ion and lithium polymer batteries. Over time, the service life may be different. It depends on the intensity of use of the mobile device. With constant use, a load of resource-intensive applications (video, games), the battery can exhaust its limit for a year. But on average, the life of lithium batteries is 3-4 years.

Charging process

It is immediately worth noting that for normal battery operation, you need to use a standard charger, which comes complete with a gadget. In most cases, it is a 5-volt DC source. Regular charges for a phone or tablet usually give a current of about 0.5–1 * C (C is the nominal battery capacity).

The standard lithium battery charging mode is as follows. This mode is used in Sony controllers and provides maximum charge completeness. In the figure below, this process is presented in graphical form.

The process consists of three stages:

- the duration of the first stage is about one hour. In this case, the charging current is kept at a constant level until the battery voltage reaches a value of 4.2 volts. At the end, the degree of charge is 70%;

- the second stage also takes about an hour. At this time, the controller maintains a constant voltage of 4.2 volts, while the charging current is reduced. When the current drops to about 0.2 * C, the final stage starts. At the end, the degree of charge is 90%;

- in the third stage, the current is constantly reduced at a voltage of 4.2 volts. In principle, this stage repeats the second stage, but has a strict time limit of 1 hour. After that, the controller disconnects the battery from the charger. At the end, the degree of charge is 100%.

Controllers that can provide such a staged, are quite expensive. This affects the cost of the battery. In order to reduce the cost, many manufacturers install controllers with a simplified charge system in batteries. Often this is only the first stage. Charging is interrupted when a voltage of 4.2 volts is reached. But in this case, the lithium battery is charged only 70% of the capacity. If the lithium battery of your device charges 3 hours or less, then most likely it has a simplified controller.

It is worth noting a number of points. Periodically (every 2–3 months) do a full battery discharge (so that the phone disconnects). Then a full charge of up to 100% is carried out. After that, take out the battery for 1–2 minutes, insert and turn on the phone. The charge level will be less than 100%. Charge fully and do it several times until the battery is fully charged when the battery is inserted.

Remember that through the USB port of a laptop, desktop, adapter from the cigarette lighter in the car, charging is much slower than from a regular memory. This is due to the current limit of the USB interface at 500 mA.

Also remember that in the cold and at low atmospheric pressure lithium batteries lose part of their capacity. At low temperatures, this type of battery becomes inoperative.