Refrigeration equipment has become so firmly entrenched in our lives that it’s even hard to imagine how one could manage without it. But classic refrigerant designs are not suitable for mobile use, for example, as a travel cooler bag.

For this purpose, installations are used in which the operating principle is based on the Peltier effect. Briefly tell about this phenomenon.

What it is?

By this term is meant a thermoelectric phenomenon discovered in 1834 by the French natural scientist Jean-Charles Peltier. The essence of the effect is the generation or absorption of heat in the area where dissimilar conductors come in contact through which electric current passes.

In accordance with the classical theory, the following explanation of the phenomenon exists: an electric current transfers electrons between metals, which can accelerate or slow down its motion, depending on the contact potential difference in conductors made of various materials. Accordingly, with an increase in kinetic energy, its conversion to heat occurs.

On the second conductor, the reverse process is observed, requiring replenishment of energy, in accordance with the fundamental law of physics. This is due to thermal vibration, which causes cooling of the metal of which the second conductor is made.

Modern technologies allow the manufacture of semiconductor module elements with maximum thermoelectric effect. It makes sense to briefly talk about their design.

Device and principle of operation

Modern modules is a design consisting of two insulator plates (usually ceramic), with thermocouples connected in series between them. A simplified diagram of such an element can be found in the figure below.

Designations:

- A - contacts for connecting to a power source;

- B is the hot surface of the element;

- C is the cold side;

- D - copper conductors;

- E is a p-junction semiconductor;

- F is an n-type semiconductor.

The design is made in such a way that each side of the module contacts either p-n or n-p junctions (depending on polarity). The pn contacts are heated, and the np contacts are cooled (see Fig. 3). Accordingly, a temperature difference (DT) occurs on the sides of the element. For the observer, this effect will look like the transfer of thermal energy between the sides of the module. It is noteworthy that changing the polarity of the supply leads to a change in the hot and cold surfaces.

Fig. 3. A - hot side of thermocouple, B - cold

Fig. 3. A - hot side of thermocouple, B - cold Specifications

The characteristics of thermoelectric modules are described by the following parameters:

- cooling capacity (Q max), this characteristic is determined on the basis of the maximum allowable current and the temperature difference between the sides of the module, measured in watts;

- the maximum temperature difference between the sides of the element (DT max), the parameter is given for ideal conditions, the unit of measurement is degrees;

- permissible current strength necessary to ensure maximum temperature difference - I max;

- the maximum voltage U max required for the current I max to achieve the peak difference DT max;

- internal resistance of the module - Resistance, indicated in Ohms;

- coefficient of efficiency - COP (acronym for English - coefficient of performance), in fact it is the efficiency of the device, showing the ratio of cooling to power consumption. For inexpensive elements, this parameter is in the range of 0.3-0.35, for more expensive models it approaches 0.5.

Marking

Consider how the typical labeling of the modules is decrypted using the example of Figure 4.

Figure 4. Peltier module marked TEC1-12706

Figure 4. Peltier module marked TEC1-12706 Marking is divided into three significant groups:

- The designation of the item. The first two letters are always unchanged (TE), they say that this is a thermocouple. The following indicates the size, there can be letters "C" (standard) and "S" (small). The last digit indicates how many layers (cascades) in the element.

- The number of thermocouples in the module shown in the photo is 127.

- The rated current in Amperes, we have 6 A.

The marking of other models of the TEC1 series is also read in the same way, for example: 12703, 12705, 12710, etc.

Application

Despite the rather low efficiency, thermoelectric elements are widely used in measuring, computing, as well as household appliances. Modules are an important working element of the following devices:

- mobile refrigeration units;

- small generators for generating electricity;

- cooling systems in personal computers;

- coolers for cooling and heating water;

- dehumidifiers, etc.

We give detailed examples of the use of thermoelectric modules.

Peltier refrigerator

Thermoelectric refrigeration units are significantly inferior in performance to compressor and absorption counterparts. But they have significant advantages, which makes it appropriate to use them under certain conditions. These benefits include:

- simplicity of design;

- resistance to vibration;

- lack of moving elements (with the exception of the fan blowing the radiator);

- low noise level;

- small dimensions;

- the ability to work in any position;

- long service life;

- low energy consumption.

These characteristics are ideal for mobile installations.

Peltier element as an electric power generator

Thermoelectric modules can work as generators of electricity if one of their sides is subjected to forced heating. The greater the temperature difference between the sides, the higher the current generated by the source. Unfortunately, the maximum temperature for the thermogenerator is limited, it cannot be higher than the melting point of the solder used in the module. Violation of this condition will lead to the failure of the element.

For mass production of heat generators, special modules with refractory solder are used, they can be heated to a temperature of 300 ° C. In ordinary elements, for example, TEC1 12715, the limitation is 150 degrees.

Since the efficiency of such devices is low, they are used only in cases where it is not possible to use a more efficient source of electrical energy. Nevertheless, 5-10 W heat generators are in demand among tourists, geologists and residents of remote areas. Large and powerful stationary installations operating on high-temperature fuel are used to power gas distribution devices, meteorological station equipment, etc.

To cool the processor

Relatively recently, these modules began to be used in CPU cooling systems of personal computers. Given the low efficiency of thermocouples, the benefits of such structures are quite doubtful. For example, to cool a heat source with a power of 100-170 W (which corresponds to most modern CPU models), it will be necessary to spend 400-680 W, which requires the installation of a powerful power supply.

The second pitfall - an unloaded processor will generate less thermal energy, and the module can cool it less than the dew point. As a result, condensation will begin to form, which is guaranteed to disable the electronics.

Those who decide to create such a system on their own will need to conduct a series of calculations to select the power of the module for a specific processor model.

Based on the foregoing, to use these modules as a CPU cooling system is not cost-effective, in addition, they can cause the failure of computer equipment.

The situation is completely different with hybrid devices, where thermal modules are used in conjunction with water or air cooling.

Hybrid cooling systems have proven effective, but the high cost limits their circle of fans.

Peltier air conditioning

Theoretically, such a device will be structurally much simpler than classical climate control systems, but everything comes down to low productivity. It is one thing to cool a small volume of the refrigerator compartment, another is a car’s room or interior. Air conditioners on thermoelectric modules will consume more electricity (3-4 times) than refrigerant equipment.

As for the use of climate control as an automobile system, the capacity of a regular generator will not be enough for the operation of such a device. Replacing it with more efficient equipment will lead to significant fuel consumption, which is not cost-effective.

Discussions on this topic periodically arise in thematic forums and various home-made designs are considered, but a full-fledged working prototype has not yet been created (apart from the air conditioner for the hamster). It is quite possible that the situation will change when modules with more acceptable efficiency appear in the public domain.

For cooling water

A thermoelectric element is often used as a cooler for water coolers. The design includes: a cooling module, a thermostat-controlled controller and a heater. Such an implementation is much simpler and cheaper than the compressor circuit; in addition, it is more reliable and easier to operate. But there are certain disadvantages:

- water does not cool below 10-12 ° C;

- it takes longer to cool than a compressor analogue, therefore, such a cooler is not suitable for an office with a large number of employees;

- the device is sensitive to external temperature, in a warm room the water will not cool to the minimum temperature;

- installation in dusty rooms is not recommended, as the fan may clog and the cooling module will fail.

Table water cooler using a Peltier element

Table water cooler using a Peltier element Peltier air dryer

Unlike an air conditioner, the implementation of an air dryer on thermoelectric elements is quite possible. The design is quite simple and inexpensive. The cooling module lowers the temperature of the radiator below the dew point, as a result, moisture contained in the air passing through the device settles on it. The settled water is discharged into a special storage.

Despite the low efficiency, in this case, the efficiency of the device is quite satisfactory.

How to connect?

There will be no problems with connecting the module, a constant voltage must be applied to the output wires, its value is indicated in the element datasheet. The red wire must be connected to the plus, the black wire to the minus. Attention! Polarity reversal swaps the cooled and heated surfaces.

How to check the Peltier element for performance?

The easiest and most reliable way is tactile. It is necessary to connect the module to the appropriate voltage source and touch its different sides. A workable element will have one of them warmer and the other colder.

If there is no suitable source at hand, you will need a multimeter and a lighter. The verification process is quite simple:

- we connect probes to the module outputs;

- we bring the lit lighter to one of the sides;

- observe the readings of the device.

In the working module, when one of the sides is heated, an electric current is generated, which will be displayed on the instrument panel.

How to make a Peltier element with your own hands?

It is almost impossible to make a home-made module at home, all the more it makes no sense, given their relatively low cost (about $ 4- $ 10). But you can assemble a device that will be useful in a hike, for example, a thermoelectric generator.

To stabilize the voltage, it is necessary to assemble a simple converter on the IC chip L6920.

A voltage in the range of 0.8-5.5 V is applied to the input of such a converter; at the output it will produce stable 5 V, which is quite enough to recharge most mobile devices. If a regular Peltier element is used, it is necessary to limit the working range of the temperature of the heated side to 150 ° C. In order not to bother tracking, it is better to use a pot of boiling water as a heat source. In this case, the element is guaranteed not to heat above 100 ° C.

The topic of cooling PC components is of concern to many users. Most of them are limited to standard air coolers, individual enthusiasts collect air-conditioning systems. What next? Surely those who were seriously interested in overclocking heard about Peltier modules (or thermoelectric modules, hereinafter referred to as TEM; the English version is TEC, Thermoelectric Cooler) and their use as heat sinks for very hot computer elements.

However, often even basic information on the proper use of these amazing devices is difficult to find, hence the numerous errors of those who first encounter them. By the way, manufacturers of cooling systems are also experimenting with Peltier modules, sometimes presenting very interesting concepts to the public. How TEMs work, whether they really are so necessary in the CO of a computer, how to assemble simple coolers on your own and to avoid the simplest mistakes that are quite typical for beginners - we will talk about all this in this material.

Bit of theory

What are Peltier modules really? In the basic definition, these are thermoelectric converters, the principle of operation of which is based on the Peltier effect, discovered back in 1834. The essence of this process is the occurrence of a temperature difference at the point of contact of the materials when an electric current flows through them.

We will not go into details of the history of the discovery and scientific justification of the specifics of TEM, since this topic can be devoted to a whole dissertation. However, we will mention general concepts.

|

| The basic scheme of the TEM device |

Peltier elements consist of two conductive materials (semiconductors) with different levels of electron energy in the conduction band. The physics of the flow of current through such substances is such that for the transition of electrons they need a certain recharge, obtained at the moment the current passes through the solder. In this case, it is possible to move particles into the high-energy conduction band from one material to another. The point of contact of the semiconductors at the time of absorption of energy is cooled. Changing the direction of the current or moving electrons from a more energetic zone to a less saturated one leads to heating of the contact point. In addition, in the Peltier modules there is a thermal effect characteristic of any substances through which electric current is passed. In general, the processes inherent in TEM are also manifested at the contact point of ordinary metals, however, it is almost impossible to determine them without complex devices. Therefore, the basis for the modules are semiconductors.

A Peltier element consists of one or more pairs of semiconductor parallelepipeds of various types (as in diodes or transistors, n- and p-type). Modern industry most often chooses silicon germanide and bismuth telluride. Semiconductors are paired with metal jumpers made of low-melting substances. The latter act as thermal contacts and directly come in contact with a ceramic plate or stand. Semiconductor pairs are connected in series, different types of conductivity are in contact with each other. On the one hand, there are only n-\u003e p-junctions, on the other hand, p-\u003e n. The current flow causes cooling and heating of the opposite groups of contacts. Therefore, we can talk about the transfer of thermal energy by the current from one side of the Peltier module to the other and, as a result, the occurrence of a temperature difference on the plate. The correct use of modules allows you to extract some benefits for industrial, including computer-based. By the way, the elements can also be used as electric generators - based on the same principles of work, the physics of the processes inside is explained by the Seebeck effect (relatively speaking, the same Peltier effect with the “opposite sign”).

Pros and cons of using TEM

Often, the advantages of Peltier modules include:

- relatively small dimensions;

- the ability to work on both cooling and heating the system;

- lack of moving parts, mechanical components subject to wear.

At the same time, TEMs have a number of drawbacks that significantly hinder their widespread practical application. Among them are the following:

- low efficiency of modules;

- the need for a current source for their operation;

- high power consumption to achieve a noticeable temperature difference and, as a result, significant heat release;

- limited dimensions and useful features.

However, despite the negative characteristics of the Peltier modules, they found their application in a number of products. TEMs are beneficial primarily where the energy efficiency of the cooler is uncritical, the less the better. Elements are used to cool charge-coupled devices in digital cameras, which can achieve a noticeable reduction in thermal noise during long exposures. Peltier modules are often used for cooling and thermostating diode lasers in order to stabilize the wavelength of their radiation. It is possible to use several TEMs arranged in succession in the form of cascades (the cold side of one cools the hot of the other), which makes it possible to achieve very low temperatures for devices with low heat generation. Peltier elements are the basis of compact refrigerators, primarily automobile ones. They are also used in miniature souvenirs from the field of computer peripherals, and in production SOs as main or auxiliary components. It is about the latter option that we will talk in more detail.

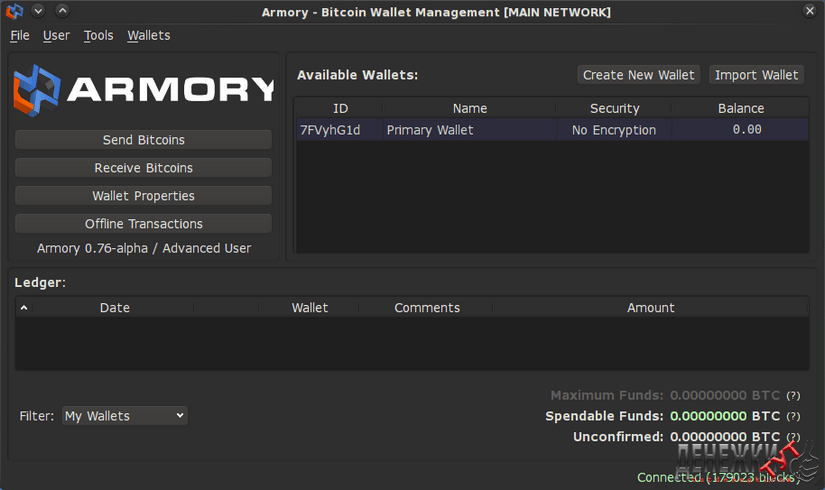

Peltier modules in PC: practice

In the transition to the practical implementation of JI based on TEM, several reservations must be made that will allow you to choose the parameters of the final structures correctly. Often, beginner's experiments end badly: either the temperatures on the “cold” side of the modules during operation turn out to be higher than on the hot side, or the systems show frankly weak results even compared to stock coolers without Peltier elements. The reasons often lie in the wrong calculation (or the construction of SO at random). The fact is that any TEM has its own standard characteristics, usually two values \u200b\u200bare distinguished (consider them using the TEC1-12709 module with the declared maximum power of 136 W as an example), for example, they write that ΔTmax Qcmax \u003d 0 (° С) 66 and Qcmax ΔTmax \u003d 0 (W) 89.2. To paraphrase this expression: the module is able to provide a maximum temperature difference between the sides equal to 89.2 ºС in the absence of heat load and 0 ºС if there is one on the “cold” side of 66 W. Thus, the payload of the module lies in the range from 0 to 66 W, ideally - the smaller - the better and the greater the temperature difference will provide TEM. At the same time, any module has a different characteristic - the maximum power consumption, which also needs to be removed from it with the help of a cooling system. For the TEC1-12709 under consideration, Umax (V) is 15.2 V, I max-9 A. Therefore, with the indicated parameters, we have an energy consumption of 136.8 W, which, you must agree, is a lot.

|

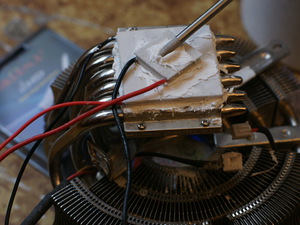

The cooling system must successfully remove heat directly from the module (providing the highest possible low temperature of the "hot" side) and PC components. You can calculate the approximate efficiency of such a system yourself - with a useful component of 150-200 watts (approximately the same amount of modern overclocked CPUs provide) you will need to spend at least 600-800 watts of electrical power and at least kilowatts of heat to get any visible results. That is why productive RMs based on Peltier modules are not widely used. However, the precedents for the relatively successful implementation of hybrid coolers are known, and we will try to create our own - low-power and optimal. To avoid restrictions in the form of insufficient heat removal, on the "hot" side of the TEM we place productive water blocks connected to the CBO circuit. By the way, Peltier modules cannot be installed directly on the core / heat-distributing cover of the chips - a thin ceramic lining is not able to support efficient heat transfer to all semiconductor pairs that make up TEM. For this purpose, an intermediate “buffer” is best suited - a copper plate with a thickness of 5-7 mm, completely covering the surface of the module. By the way, the optimal operating mode of Peltier elements is ensured at low voltage and current consumption. Approaching these parameters to the maximum significantly increases the thermal efficiency of the plate, but not so noticeably - a useful component.

We decided to cool the graphics chip of the Radeon HD 4350 and CPU Core 2 Duo E8500 to the maximum, trying to overclock these components. To remove heat from the GPU, we used the already mentioned TEC1-12709 (maximum power consumption - 136 W) and a home-made copper water block, TEC1-12726 (395 W) and one of the best industrial water blocks Swiftech Apogee GT worked together with the processor. The modules were connected directly to the computer power supply in a 12-volt circuit. Application of kilowatt be quiet! Dark Power PRO BQT P6PRO-1000W gave every reason not to worry about the lack of power to power the PC and elements of the cooling system. Two “double” radiators for 120 mm fans and a Hydor Seltz L30 pump (1200 l / h at idle) worked in the SVO circuit.

In the case of cooling components to temperatures below room temperature (in particular, below the "dew point"), condensation should be expected on supercooled surfaces. It is clear that water in this form is the main enemy of the user, and its allocation must be prevented. This is done by careful thermal insulation of any surfaces (parts of the PCB, near-socket space on both sides of the board, actually TEM, processor heat distributor and GPU) with materials that do not allow air to pass through. Best for this purpose is standard thermal insulation material for water pipes (based on foamed rubber), special putties, certain types of foam rubber, supplied with PC components, thermal grease and paper towels at worst. In the latter case, PC operation is permissible only for short-term benchmarking sessions. Thermal insulation will increase the overall efficiency of the installation.

The final temperatures obtained in various operating modes of the components, their comparison with indicators provided exclusively by the water cooling system, are shown in the diagram. As you can see, Peltier modules allowed to lower the temperature of the components significantly below room temperature (depending on the load). Under such conditions, it was not difficult to overclock the processor to a frequency of 4.3 GHz with increasing the supply voltage to 1.35 V, and make the GPU operate at 800 MHz (the standard value is 600 MHz). At the same time, we got a noticeable heating of the test bench CO (in the case, the situation would have been aggravated more significantly) and a sharp increase in the PC power consumption level (in fact, the whole design consumes more than a single computer based on test bench components). Such a solution will definitely come in handy in the winter, but in the summer most users are unlikely to please.

Are you ready for such sacrifices to achieve relatively low temperatures on PC components? Decide for yourself, but remember the basic tips provided in this part of the material - they will help to correctly apply Peltier modules in practice. The use of TEM-based cooling systems is reasonable and justified in the case of low-power components (motherboard chipsets, GPUs for low- and mid-level video cards). Do not forget about the thermal insulation of the cooled elements - after all, condensate is the main enemy of the system during experiments with TEM.

findings

|

Summarizing the above regarding the features of the Peltier modules and the appropriateness of their practical application, we repeat: TEM have the mentioned advantages and disadvantages that do not allow us to give an unambiguous answer to the question: "Is it worth it ...?" include compact refrigerators, thermostatically controlled lasers; CO for low-power PC components - chipsets and individual GPUs).

Various home-made cooling and heating devices can be created on the basis of Peltier elements; there are examples of successful implementation of low-power generators. But before you engage in the manufacture of such structures, familiarize yourself with the theoretical component - preliminary preparation will save you from mistakes and save time at the time of practical implementation of projects.

Talking about the use of Peltier modules in a PC should be done quite carefully: after reading about getting low temperatures on cooled elements, beginners often forget about the significant consumed and allocated power of such COs, do not take into account the parameters and the "safety margin" of a single design. TEM will be of interest primarily to overclockers, for whom any winning degree and every megahertz are important. The elements under consideration are an intermediate link between classic water cooling systems and chillers or freons working on the principle of a phase transition. However, the use of TEM can not be called simple, so before you start serious experiments, carefully weigh the pros and cons.

Ready-made SOs based on TEM

Peltier modules are used by manufacturers of PC cooling systems as the main and auxiliary components of coolers. Sometimes effective effective devices are obtained from this, sometimes everything does not work out as smoothly as originally intended. We decided to recall the main SOs that use TEM, which they predicted the role of revolutionaries of their time.

One of the first coolers with a Peltier element, which made a lot of noise in the field of CPU cooling (2003). However, a low margin of safety, significant energy consumption at that time, the bulkiness of the structure and noise in operation did not allow it to gain a foothold in the market. If this model appeared a year or two earlier, perhaps everything would have turned out differently.

A super cooler for video cards, built on the same principle as the Titan Amanda: one half of the radiator works directly to remove heat from the GPU, the other cools the hot side of the TEM. At one time, it turned out to be one of the best during the testing of CO for graphic adapters. (We wrote about it in Home PC in 2007.)

The most powerful modern CPU cooling solution using the Peltier element. It is a productive water block that removes heat from the TEM (about 400 W of consumed electrical power), which, in turn, creates the optimal temperature regime of the processor. This system is able to ensure the operation of Core i7 at a frequency of about 4 GHz at a temperature of about 0 ºС (idle time) and 20-30 ºС at maximum load.

Similar to the processor solution, it is a high-performance water block for a graphics adapter, supplemented by a Peltier module. Depending on the TDP, the video chip is able to keep its temperature at room temperature or lower.

The Peltier elements of this CO cool part of the heat pipes. The approach is quite interesting and correct, the use of modules allows you to bring down a couple of degrees on the processor. However, the economic feasibility of such a move is a big question, due to the fact that the V10 at a significant price is not able to overtake the best air supercoolers. Most likely, the design features and insufficient TEM power are to blame.

A series of fairly modern processor heatpipe supercoolers using a thermoelectric module (2007-2008). Part of the radiator removed heat directly from the TEM, while the other half cooled the heating component. Such an approach to design allows avoiding a sharp overload of CO due to exceeding the limits of heat emission of the Peltier module. Amanda coolers showed excellent results with processors with a relatively low TDP.

XtremeLabs.org MONSTER T.E.C. Project

Owners of water cooling systems and those who are going to acquire liquid systems may be interested in the so-called chillers based on Peltier elements. Depending on the type of TEM connection to the circuit, they will allow to slightly lower the temperature of the coolant, and when creating powerful COs, they will even provide a coolant temperature close to zero.

The well-known enthusiast Wehr-Wolf has long been interested in the subject of effective cooling of PC components and their further extreme overclocking. It all started back in 2005 with theoretical sketches, considerations, and one of the main components of the system - a massive “sandwich” consisting of large water blocks. However, the ideas that were abandoned for a long time could be realized only together with the author of this material, in the middle of this year by launching the enthusiastic project XtremeLabs.org MONSTER T.E.C. Project

First start-up of a TEM chiller in the field

The principle of operation of the system is quite simple: Peltier modules (8 TEMs with a maximum power consumption of 136 W each) cool a large copper water block on both sides, and they themselves, in turn, are cooled by similar water blocks. The “cold” and “hot” circuits of the water cooling system are completely separated from each other. To supply such a quantity of TEM during the first start-up, two computer PSUs with a total declared power of 1200 W were used, as a cooler of the "hot" circuit, a SOF with two radiators under two 120-mm fans each pumped by a powerful pump was used. However, even such a CBO was not enough, and the radiators had to be purged with high-performance industrial fans. A Hydor L20 II pump and a Swiftech Apogee GT water block were connected to the “cold” circuit; a large water block in contact with the “cold” side of the TEM acted as a cooler. As a result of the first experiment, it was possible to achieve a water temperature in the circuit of the order of 5-7 ºС, while the Core i7 965 Extreme Edition processor, overclocked to a frequency of 4 GHz, was used as a load for the system.

On the one hand, the results obtained are really impressive - only chillers based on phase transition systems can provide such temperatures at such loads, and on the other - is it worth the effort? The monstrous power consumption of the system, the cumbersome SO of the "hot" circuit, the high total cost are justified only by the conceptual status of XtremeLabs.org MONSTER T.E.C. Project, currently under development.

Peltier thermoelectric cooler.

The principle of operation was borrowed from neta: The basis of the Peltier elements is the contact of two conductive materials with different levels of electron energy in the conduction band. When current flows through the contact of such materials, the electron must acquire energy in order to transfer to a higher-energy conduction band of another semiconductor. When this energy is absorbed, the contact point of the semiconductors is cooled. When the current flows in the opposite direction, the contact point of the semiconductors is heated, in addition to the usual thermal effect.

When metals come into contact, the Peltier effect is so small that it is invisible against the background of ohmic heating and heat conduction phenomena. Therefore, in practical use, the contact of two semiconductors is used.

Appearance of the Peltier element. When a current is passed, heat is transferred from one side to the other. A Peltier element consists of one or more pairs of small semiconductor parallelepipeds - one n-type and one p-type in a pair (usually bismuth telluride, Bi2Te3 and silicon germanium), which are paired using metal jumpers. Metal bridges simultaneously serve as thermal contacts and are insulated with a non-conductive film or ceramic plate. The pairs of parallelepipeds are connected in such a way that a series connection of many pairs of semiconductors with different types of conductivity is formed, so that at the top there are one sequence of compounds (n-\u003e p), and the bottom are opposite (p-\u003e n). Electric current flows sequentially through all parallelepipeds. Depending on the direction of the current, the upper contacts are cooled, and the lower ones are heated - or vice versa. Thus, an electric current transfers heat from one side of the Peltier element to the opposite and creates a temperature difference.

If you cool the heating side of a Peltier element, for example with a radiator and a fan, then the temperature of the cold side becomes even lower. In single-stage elements, depending on the type of element and the magnitude of the current, the temperature difference can reach approximately 70 K /

Description

The Peltier element is a thermoelectric converter, which, when voltage is applied, is able to create a temperature difference on the plates, that is, to pump heat or cold. The presented Peltier element is used for cooling computer boards (subject to efficient heat removal), for cooling or heating water. Peltier elements are also used in portable and automobile refrigerators.

Peltier cell powered by 12 volts.

For heating, you just need to change the polarity.

Peltier plate dimensions: 40 x 40 x 4 millimeters.

Operating temperature range: from -30 to +70? ..

Operating voltage: 9-15 volts.

Power Consumption: 0.5-6 A.

Maximum power consumption: 60 watts.

Funny little thing, we connect 12v + - it cools; we change the polarity; it warms up. It is used in many car refrigerators, in any case I have one. You can attach a compact scheme to the glove compartment so that chocolate would not melt in the summer! For use and effective use, you need to use a cooling radiator - as a test I used a radiator from a computer processor, it is possible with a cooler. The better the cooling, the Peltier effect is stronger and more efficient. When connected to a car battery at 12v, the consumption current was 5 amperes. In a word, the element is gluttonous. Since I have not yet assembled the entire circuit, but conducted only trial tests, without instrumental temperature measurements. So, with a cooling mode, a slight frost appeared within 10 minutes. In the heating mode, the water in a metal cup boiled. The efficiency of this cooler, of course, is low, but the price of the device and the ability to experiment make the purchase justified. The rest is in the photo

You can heat any objects. This can be a soldering iron, electric kettle, iron, hair dryer, various kinds of heaters, etc. But have you heard that it is possible to cool with the help of electric current? “Well, what about, for example, a household refrigerator?” You say. And you will be wrong. In a domestic refrigerator, an electric current has only an auxiliary function: it drives freon in a circle.

But are there such radio elements that, when an electric current is supplied to them, produce cold? It turns out there are ;-). In 1834, the French physicist Jean Peltier discovered heat absorption during the passage of an electric current through the contact of two dissimilar conductors. Or, in other words, in this place low temperature was observed. Well, as it should be in physics, in order not to come up with a new name for this effect, it is called in honor of the one who discovered it. Discovered something new? Responsible for the bazaar)). Since then, this effect has been called. peltier effect.

Well, oddly enough, the element that produces the chill is called peltier element - this is thermoelectric converterwhose operating principle is based on the Peltier effect - the occurrence of a temperature difference during the flow of electric current. In English literature, Peltier elements are designated Tec (from English Thermo Electric Cooler - thermoelectric cooler).

Peltier element (practice)

It may look different, but its main appearance is a rectangular or square platform with two leads. Immediately noted side “A” and side “B” for further experiments

Why did I tag the parties?

Do you think that if we just stupidly apply voltage to this element, it will completely cool down here? I do not want to disappoint you, but this is not so ... Once again we carefully read the definition about the Peltier element. See the phrase “temperature difference” there? That and that. So, some side will warm up here, and some side will cool. There is nothing perfect in our world.

In order to determine the temperature of each side of the Peltier element, I will use the one that came with the thermocouple

Now it shows room temperature. Yes, I'm warm ;-).

In order to determine which side of the Peltier element is heated and which is cooling, for this we hook the red lead to plus, the black one to minus and apply a bit of voltage, two or three volts. I found out that side “A” is cooling down, and side “B” is warming by touching them with my hand. If you reverse the polarity, nothing bad will happen. Just side A will heat up, and side B will cool, that is, they will change roles.

So, the nominal (normal) voltage for the Peltier element is 12 volts. Since I connected to red - plus, and to black - minus, then my side B is warming. Let's measure her temperature. We apply a voltage of 12 volts and look at the readings of the multimeter:

77 degrees Celsius is not a joke. This side is heated so that when you touch it, it burns your fingers.

Therefore, the main feature of using the Peltier element in their electronic devices is large radiator. It is desirable that the radiator is blown by a fan. I have so far taken the radiator from the amplifier, which was given for repair. I coated the thermal paste KPT-8 and attached the Peltier element to the radiator.

We supply 12 volts and measure the temperature of side A:

7 degrees Celsius). When you touch, your fingers freeze.

But there is also the opposite effect, in which it is possible to generate electricity using the Peltier element, if one side is cooled and the other heated. A very significant example is a flashlight that works from the heat of the hand

Peltier element power

The Peltier element itself is considered very energy-intensive. Temperature regulation of its sides is achieved by voltage. The higher the voltage, the more current it consumes. And the more current it consumes, the faster it gains temperature. Therefore, you can adjust the chill by stupidly changing the voltage value).

Here are some values \u200b\u200bfor electric current consumption by a Peltier element:

At a voltage of 1 volt, he eats 0.3 amperes. Not bad)

I increase the voltage to 3 volts

Almost 1 Amp eats.

I increase to 5 volts

A little more than one and a half amperes.

I give 12 Volts, that is, its operating voltage:

It’s already eating almost 4 amperes! Robbery).

Let's roughly calculate its power. 4x12 \u003d 48 watts. This is even more than a 40-watt light bulb that hangs in your pantry). If the Peltier element is so voracious, is it advisable to make household refrigerators and cold stores from it? Of course not! Such a refrigerator you will eat Kilowatt 10 no less! But there is one small plus - it will be absolutely silent :-). But if there is no possibility, then they make refrigerators even from Peltier elements. These are mainly mini car refrigerators. Also, some use the Peltier element to cool the processor on a PC. It turns out very efficiently, but in terms of energy consumption it is better to install the good old fan.

Where can I buy

On Ali you can even find a mini air conditioner from a Peltier element here this link.

![]()

On Ali of these Peltier elements you can choose as much as you like!

A Peltier element is a thermocouple, in other words, a device that changes temperature and works in accordance with the Peltier principle of the same name, that is, demonstrating the temperature difference that occurs from the moment of supply of electricity. In English sources it appears as a thermoelectric cooler. The inverse of this effect is called the Seebeck effect.

The principle of operation of the device

The Peltier element operates due to the interaction of one conductive material with another, different in the energy level of electrons in the conductive region. Passing through such a communication channel gives the electron a large energy reserve, which then allows it to go into the conducting region with a higher energy level. The absorption of this energy leads to a decrease in temperature at the point of connection of the conductors. When the reverse current flows, the contact heats up, which finds expression in the form of a standard thermal effect.

Provided that a heat sink is connected on one side, during operation of the radiator system, the second side gives strong cooling (up to tens of degrees below the ambient temperature level). A direct relationship is observed between the magnitude of the current and the degree of cooling. When changing polarity, the positions of the sides of heating and cooling also change.

When a Peltier element interacts with parts made of metal, the effect exerted by it decreases many times, and the temperature contrast becomes little noticeable under the influence of various phenomena associated with the thermal conductivity of the circuit. For this reason, practical application involves the use of two semiconductors at once.

You can combine thermocouples in any quantities within hundreds, which makes it possible to create a Peltier element of any refrigerating capacity.

Thermoelectric module

The Peltier effect can be observed especially clearly when using p- and n-semiconductors. In accordance with the direction of the electric current, when passing through the pn compound, absorption or energy release takes place.

It is this design that is used in TEM (thermoelectric module). A single element of a thermoelectric module is one whose design is a combination of a p- and n-conductor. If several similar elements are connected in series, then the absorption of heat will occur at the n-p-contact, and the release at the p-n-contact. As a result, the previously described situation with a temperature difference arises. According to the generally accepted principle, the side to which the wires are connected is hot and in the diagram it is always located below.

Fig. 1: Peltier thermoelectric module

In TEM, thermocouples are fixed between a pair of plates of ceramic materials. Each of the branches is soldered with copper conductive pads (busbars), which in turn are bonded to a heat-conducting material, for example, aluminum oxide.

Determine the level of the operating voltage of the module should be based on the number of components. The most common option is 127-pair modular designs with the highest voltage level of 16 volts. But 75% of this value is usually enough for their work. Moreover, this figure is the most suitable, since it also meets the requirements for working conditions, and is quite economical. With increasing voltage, the power will hardly increase, but power consumption will increase significantly.

Practical application

To date, the use of the Pelt element is especially relevant in devices of the following types:

- Refrigerators;

- Air conditioners;

- Car coolers;

- Water coolers;

- Video cards for a personal computer.

In general, it can be said that the Peltier element has become an integral part of a variety of refrigeration and air conditioning systems. Using this device is an excellent approach to solving the problem of equipment overheating. Currently, the Peltier element can also be used to cool the acoustic and sound system, since its operation is completely silent and ideal for such purposes.

There are several qualities of the Peltier element that are in great demand:

- They provide a fairly powerful heat transfer;

- They have very modest sizes, which allows you to use them in almost any device;

- Able to maintain the same temperature over a long period of time (thanks to radiators);

- They have a considerable durability, as they are equipped with a number of solid immovable components.

The simplest component of the element looks like a pair of copper conductors to which contacts are connected, connecting wires equipped with an insulating element (stainless steel or ceramic is used for its manufacture).

How to make a Peltier element yourself

The simplicity of the design of this device has to do it yourself. Moreover, the scope of its practical application is practically unlimited: refrigerators, air conditioners and other equipment.

Previously, you should prepare a pair of metal plates, and you will also need wiring with contacts. First of all, stock up with conductors to be installed near the base of the device. For these purposes, PP conductors are best suited.

Next, do not forget that semiconductors must be installed at the output, which will supply heat to the upper plate. To mount the element, you need a soldering iron. At the final stage, you need to connect a pair of wires. One is localized near the base and securely mounted next to the outermost conductor. It is important that there is no contact with the plate.

The attachment point of the second conductor is located near the upper part and is fixed in the same way - at the extreme conductor.

To check the item for performance, you will need to use a tester. The device is connected to the wires and the voltage is measured. The standard voltage deviation reaches approximately 23 volts.

The power of the Pelt element is directly dependent on its dimensions, this should be taken into account when assembling or installing it yourself. Installing an insufficiently powerful element will not prevent the breakdown of equipment, but only delay it. At the same time, excess power causes the temperature level to drop to a critical level, when moisture in the air can begin to condense and settle on the surface of devices, which is especially dangerous for electronic devices.

In addition, the other side of the module is a source of a sufficiently large amount of heat, therefore, to ensure its safe operation, a rather large fan is required.

How to make a generator based on a Peltier element?

Generators based on the Peltier element are especially interested in people who, because of their sufficiently long isolation from civilization, need a simple and affordable source of energy. They are also widely used for critical overheating of personal computer parts.

Fig. 2: Peltier-based generator.

Peltier elements have a rather interesting principle of action, but in addition they have one curious feature: if a temperature difference is attached to them, then they produce electricity. One of the options for a generator based on this device involves the following design:

Steam flows through two tubes (one for entry and one for exit), which is sent to the cavity of the heat exchanger constructed of a plate (material: aluminum), which has a thickness of 1 cm.

A connection with one channel is connected to each opening of the heat exchanger. The dimensions of the heat exchanger exactly duplicate the dimensions of the Peltier elements. Two elements are fixed on two sides of the heat exchanger with four screws (2 on each side). As a result, thanks to the openings and tubules of the heat exchanger, a complete system of communicating departments is formed through which steam passes. Moving forward, steam enters the chamber through one tube and exits through another, moving to the next chamber. The heat transmitted by the steam goes to the Peltier elements when the steam comes in direct contact with their surface, as well as with the material of the heat exchanger.

To close the elements against the body of the heat exchanger, as well as to organize the removal of thermal energy to the "cold" side, aluminum plates are used 0.5 cm thick. At the last stage, the entire structure is sealed with silicone sealants.

After that, steam is released through the tubes, and the structure is immersed in cold water. The whole system begins to work. Electric current will be generated until the difference between the temperature of the “hot” and “cold” sides is reduced to a minimum.

There is a more elementary method.

The Peltier element with the leads connected to the charging telephone cable is mounted on an aluminum radiator (which will contact the “cold” side) with the help of a sealant. On top of the device is any hot item, such as a mug of hot tea. After a couple of seconds, the phone can be charged. Charging will continue until the tea has cooled.

Write comments, additions to the article, maybe I missed something. Take a look at it, I will be glad if you find anything else useful on mine.