What are the types of lithium batteries and their design features?

Lithium batteries in the modern market have firmly occupied several different niches. They are mainly used in all kinds of consumer electronics, portable tools and mobile devices, household appliances, etc. There are even 12 volt lithium batteries for cars. Although widespread in the automotive industry, they have not yet received. The use of lithium batteries in various sectors of the economy has led to the appearance on the market of many varieties of these batteries. The main types of lithium batteries we will consider in today's article.

Here we will not write about the principle of operation of Li rechargeable batteries and the history of their occurrence. Details can be found in the article at the specified link. You can also read the materials separately about and. And in this material I would like to consider precisely the different types of Li batteries, depending on their characteristics and purpose.

So, as for the power and capacity of lithium batteries. The division is rather arbitrary. In order to produce batteries of different capacities, with different discharge currents, manufacturers change a number of parameters. For example, they control the thickness of the electrode mass layer on the foil (in the case of a roll construction). In most cases, this electrode layer is applied with copper (minus electrode) and aluminum (plus) foil. Due to this increase in the electrode layer, the specific parameters of the battery increase.

However, when building up the active mass, it is necessary to reduce the thickness of the conductive base (foil). As a result, the battery can pass less current without overheating. In addition, an increase in the electrode mass layer leads to an increase in the resistance of the cell. To reduce resistance, often more active and dispersed substances are used for the active mass. Manufacturers “play” with these parameters when releasing batteries with one or another parameter. A thin foil battery with a thick active mass shows high values \u200b\u200bof stored energy. And its power will be low, and vice versa. And this can be adjusted without changing the size of the product.

Rechargeable batteries with different values \u200b\u200bof capacity and discharge current are obtained by changing the following parameters:

- Foil thickness;

- Separator thickness;

- Material of plus and minus electrode;

- Particle size of the active mass;

- The thickness of the electrode.

At the same time, battery models designed for higher power are equipped with current leads of large sizes and weights. This is to prevent overheating. Also, to increase the discharge current, all kinds of substances are used that are added to the electrolyte or to the electrode mass. For batteries with a large capacity, the current outputs are usually small. They are designed for discharge current up to 2C (usually the charge-discharge current of the battery is indicated from its capacity) and charging ─ up to 0.5C. For lithium batteries of high capacity, these values \u200b\u200bare up to 20C and up to 40C, respectively.

High power lithium battery models are designed to power starters, with high capacity - to power various portable equipment. As for the development of lithium batteries, manufacturers of all kinds of electronics order them in special firms. Those develop them taking into account the proposed conditions, and then place them in mass production. When developing modern lithium batteries, the following parameters are taken into account:

- Capacity;

- Regular and maximum discharge current;

- Sizes

- Location conditions inside the device;

- Working temperature;

- Resource (number of charge-discharge cycles) and others.

Various designs of lithium batteries

According to the design features of lithium batteries can be divided into two signs:

- Housing design;

- Electrode design.

Electrode Design

Roll type

In the image below you can see the Li─Ion battery with a roll type design.

Elements of a roll design are made of two types:

- A roll of electrodes twists around a virtual plate. In one case several rolls connected in parallel can be placed;

- Cylindrical. Different heights and diameters.

Roll construction is used where a small capacity battery and power are required. This technology has a small amount of labor, since the twisting of the electrode strips and the separator is fully automated. The disadvantage of this design is poor heat removal from the electrodes. In fact, heat is removed only through the end face of the element.

From a set of electrodes

Lithium batteries with an assembly of individual electrodes are used in the production of prismatic batteries.

Heat is also removed here from the end of the electrode. Manufacturers are trying to improve heat dissipation by adjusting the composition and dispersion of the active mass.

Housing design

Cylindrical

Attention should be paid to cylindrical lithium batteries. They are widely distributed in various household appliances and electronics. Battery cells are especially popular.

As the advantages of a cylindrical body, experts call the absence of a change in volume during long-term operation. This is due to the fact that the battery changes a little during the charge-discharge process. The design of the electrodes in such a housing is always of a roll type. The disadvantages include poor heat dissipation.

Cylindrical lithium batteries can have the following current outputs:

- Helical boron;

- Conventional pads.

Where higher requirements for current extraction are used, screw borons are used. This is a battery with a large discharge current and a large capacity (more than 20 Ah). Numerous tests show that cylindrical lithium batteries with helical boron can withstand currents of not more than 10-15C. And these are the values \u200b\u200bof the short-term load at which the element quickly overheats. With prolonged use, they withstand discharge currents of 2–3C. Mainly used in portable power tools.

Battery cells with contact pads are commonly used to combine into batteries. To do this, they are welded with a tape using resistance welding. Sometimes manufacturers already produce elements with petals for soldering. Moreover, the appearance of the petals may be different depending on the type of soldering.

In the designation of the standard size of cylindrical lithium batteries, their sizes are usually present. For example, lithium ion cells 18650 have a height of 65, and a diameter of ─ 18 mm.

Since any battery (accumulator) is a source of constant electric current, sooner or later its charge will inevitably be depleted. With each recharge, its capacity will be less and less. These are the laws of physics.

You can only briefly extend her work. Consider how to restore a lithium-ion battery to gain the time it takes to replace a battery.

IMPORTANT. If you are new to technology, then further, in general, it costs nothing to read - just go for a new battery or invite a competent friend. (Do not call Kuma!).

In addition, you will learn about the causes of fire, explosion hazard, aging LIA. This information will help determine what exactly happened with the battery, and will also make it possible to avoid operational errors.

So, - lithium-ion type batteries (LIA) are used in a wide range of various modern technology as a source of email. energy from mobile phones to storage devices in energy systems.

Their main performance indicators can vary within such limits (it depends on their chemical composition):

- Voltage (nominal) - 3.7 V or 3.8 V;

- Maximum voltage - 4.23 V or 4.4 V;

- The minimum voltage is 2.5–2.75 V or 3.0 V;

- The number of charge discharges - 600 (with a loss of 20% capacity);

- Internal resistance 5–15 mOhm / Ah;

- Under normal conditions, the value of self-discharge is 3% per month;

- Operating temperature range - from minus 20 ° C to plus 60 ° C, optimal - plus 20 ° C.

- If an overvoltage occurs during charging of the LIA, then it may ignite. To protect against this, a controller is inserted into the case. Its function is to disable LIA. (Also controlling current, overheating and discharge depth).

- To reduce the cost, not every lithium battery is equipped with a controller (or it does not protect in all respects).

INTERESTING: Sony became the first manufacturer of lithium batteries in 1991.

Device and advantages of LIA

The LIA consists of a cathode (on aluminum foil) and an anode (on copper foil), separated by an electrolytic separator and placed in a sealed “jar”.

The cathode and anode are connected to the collector terminals.

The housing is sometimes equipped with a valve to relieve pressure during emergency operating times.

In a lithium-ion battery (LIA), the charge is transferred by a lithium ion. Its characteristic ability is the ability to penetrate into the crystal lattice of other materials (in our case, it is graphite, oxides or metal salts), thus forming chemical bonds.

Three types of cathode materials are currently used:

- Lithium cobaltates (due to cobalt, the number of charge-discharge cycles increases, as well as the possibility of operation at low temperatures);

- Lithium Manganese

- Lithium ferrophosphate (low cost).

- The advantages of LIA are low self-discharge, a large number of cycles.

LIA disadvantages

The explosion hazard of Li-ion batteries in the first generation was justified by the occurrence of gaseous formations, which led to a short circuit between the electrodes. This has now been eliminated by replacing the anode material from lithium metal to graphite.

Explosion hazard also occurred in cobalt oxide LIB in case of operational disruptions.

Lithium ferrophosphate-based LIAs are completely devoid of this drawback.

IMPORTANT. Discharging LIA at low temperatures (especially repeated) leads to a decrease in energy for the return to tens of percent. In addition, the LIA “sharply” react to the temperature during charging: the optimal one is +20 ° C, and +5 ° C is not recommended.

Memory effect

Studies have confirmed the existence of a memory effect in LIA. But the essence lies in its fundamental presence, and not in its influence on the work as a whole.

The explanation of this process is as follows: the operation of the battery consists in the periodic release and capture of lithium ions, and this process worsens when the charge is incomplete due to the violation of the microstructure of the electrode.

IMPORTANT. Specialists identified two rules for extending the LIA service:

- Prevention of full discharge;

- Do not charge near heat sources.

Aging

LIAs age even out of service. Twenty percent of the capacity is lost after two years. You should not buy them "at the table." Look at the date of purchase when buying.

Low temperatures and power

Up to fifty percent of battery power is lost at operating temperatures below 0 ° C.

Spontaneous combustion

LIA are prone to spontaneous combustion. During thermal acceleration of a faulty (damaged) battery, substances are released that accelerate its self-heating (oxygen plus combustible gases). Therefore, it is capable of burning even in the absence of air.

To extinguish in such cases, provide for lowering the temperature and prevent the spread of fire.

Getting down to recovery

After you already know from the above “physicist” and “chemistry” the work of LIA and its filling, you will be able to choose one of the methods for treating your battery yourself, as well as evaluate the “reasonableness” of the methods below.

Get rid of gases

We already know that with improper use, gaseous substances can form inside the “jar”.

The essence of this method is that you need to get rid of them. To do this, first remove the upper block (controller), then pierce the discovered cap, and then press it against a hard surface with some kind of press to release gases.

After that, seal the hole with epoxy resin and return the controller to its place.

But before reviving the phone’s battery in this way, be aware of the expected dangers of this method:

- Damage to the device by excessive exposure;

- Damage to the electronics under the cap;

- The possibility of explosion (spontaneous combustion) when the cathode closes with the anode.

Short-term "return" of capacity

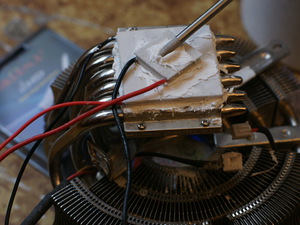

You can revive the battery for a short time if you carry out a “revival” using a 5-12 volt power supply, a resistor from 330 to 1000 Ohms and a power of at least 500 mW.

To do this, the contacts of the power supply are connected to the LIA contacts: minus to minus, and plus to plus through a resistor, the polarity of which is checked with a multimeter. Consumption time - no more than two to three minutes.

Please note that the parameters of the supplied current must correspond to those required, and control the voltage with a voltmeter or tester.

We use a refrigerator

Following this simple method, the battery is restored as follows:

the battery removed from the smartphone must be placed in the refrigerator for a period of twenty to thirty minutes, previously placed in a plastic bag. Then connect for one minute to charge, and then wait until it warms up to room temperature.

Allegedly, after these manipulations it can be used as usual.

Charge-discharge method

This method should have been called a battery resuscitation method for a fifth grade student.

According to the popularizers of this "joke", you can "bring to life" the battery of the phone by "several times" (the number of times not indicated) one hundred percent charge and the subsequent complete discharge of the battery. For discharge, it is advised to use some resource-intensive game or AnTuTu utility, each time for this purpose removing and inserting it back into the mobile phone.

It remains unclear how the battery will be charged several times to 100 percent if it is already inoperative?

"Wild" recovery method

This “maneuver” consists in the fact that after removing the protective controller, it is necessary to close the output terminals-collectors with a metal object. After that, the controller returns to its place.

At the same time, one more significant point is added - at the beginning of the procedure, for some reason, you need to unstick the sticker with the technical characteristics of LIA. Here truly "dancing with a tambourine"!

Swing LIA disabled by the controller

To prevent deep discharge, lithium-ion batteries are equipped with a controller that immerses it in the “shutdown”. In this case, when measuring the voltage at its terminals in front of the controller, you can detect a value of about 2.5 volts. So the battery is still alive!

To do this, the protection circuit is first disconnected (soldered).

"Bank" is connected to a universal device for charge-discharge (for example, Turnigy Accucell 6). In this case, the device itself monitors the process and recovery takes place under its control.

The TYPE button selects the Li-Po charge program, because our LIA is 3.7V.

By short pressing “START” the charge parameters are selected. For Li-ion - the value is 3.6 V, for Li-pol - 3.7 V.

It is necessary to select “AUTO” for the parameter, since in our case the charge will not start due to the low battery charge.

The charge current must be set at ten percent of the battery capacity (in our case, 150 mA). The value is set using the “+” and “-” buttons.

When the charge in the 4.2 V battery is reached, the device will be put into voltage stabilization mode, and upon completion of the process, an audible signal will sound and the message “FULL” will appear on the display.

And finally, a video on how you do not need to restore batteries

Safety notes

Before restoring a lithium-ion battery, you should remember the following rules:

- You can not leave the problematic LIA during repairs unattended. Spontaneous combustion is not a threat, but a real fact.

- It is necessary to periodically monitor the temperature of the phone’s battery with an external thermocouple, you can use an electronic thermometer or at least by hand. If the surface seemed hot rather than warm, repair should be stopped immediately.

- Do not use high currents to charge. The possible maximum allowed is 50 mA. This parameter is calculated by dividing the power supply voltage by the capacity of the resistor. For example, at 12 V and 500 Ohms - it will be 24 mA.

- Instead of a resistor, the use of a standard 80 mm fan for a computer is acceptable.

Remember that the above methods do not give a one hundred percent result, and in any case, the responsibility lies with you. This is especially true for the humanities.

Do not overestimate your knowledge and capabilities. Better once again consult with knowledgeable people.

And share your experience with friends and write in the comments.

You are wondering: “What to choose: a Li-Ion or a Li-Po battery?” We will explain in detail what is the difference between these two types of batteries.

As we all know, the power of a portable charger is more dependent on the quality of the batteries inside the device. In the modern market, there are two types of batteries that are used to produce portable chargers: Li-Ion and Li-Po battery cells.

Li-Ion or Li-Po: What is the Difference and What to Choose

For your information, one of the most frequently asked questions regarding portable chargers is: what is the difference between Li-Ion and Li-Po batteries, and which one is better. Let's get it right.

What are Li-Ion and Li-Po?

Li-ion is short for lithium-ion, and Li-Po is for lithium-polymer. The ending “ionic” and “polymer” is an indication of the cathode. A lithium-polymer battery consists of a polymer cathode and a solid electrolyte, and a lithium-ion battery consists of carbon and a liquid electrolyte. Both batteries are rechargeable, and then, in one sense or another, they both perform the same function. In general, lithium-ion batteries are older than lithium-polymer batteries, but they are still widespread due to their low price and low maintenance. Lithium polymer batteries are considered to be more advanced, with improved characteristics that provide a higher level of safety, therefore, such batteries are more expensive than lithium-ion batteries.

There are many configurations of Li-Ion batteries. The most common lithium-ion batteries for portable chargers are batteries with a size of 18650, a diameter of 18mm and a length of 65mm, in which 0 means a cylindrical configuration. More than 60% of portable charges are made of battery cells with a standard size of 18650. The size and weight of such cells makes it easy to use them in many electronic devices. Manufacturing technology also does not stand still.

As demand for lighter and more compact portable chargers grows more and more among buyers, the limitations that lithium-ion batteries entail are becoming increasingly apparent. Therefore, manufacturers are switching to the production of lighter, flatter modular lithium-polymer batteries for new portable chargers. Moreover, lithium-polymer batteries are not at such a risk of explosion, and therefore, portable charges no longer need to incorporate a protective layer, while most lithium-ion 18650 batteries should only be installed with protection.

Let's summarize the table of differences between the lithium ion and lithium polymer.

| Key Features | Li-ion | Li-Po |

| Energy density | High | Low with fewer cycles compared to Li-Ion |

| Versatility | Low | High, manufacturers are not tied to the standard cell format |

| The weight | A bit heavier | Lungs |

| Capacity | Below | The same volume of Li-Po battery, almost twice as much as Li-Ion |

| Life cycle | Big | Big |

| Explosion hazard | Higher | More sophisticated safety reduces the risk of overcharging as well as electrolyte leakage. |

| Charge time | Slightly longer | shorter |

| Wear and tear | Loses less than 0.1% of its effectiveness every month | Slower Than Li-Ion Batteries |

| Cost | Cheaper | More expensive |

After studying all the advantages, disadvantages and characteristics of the two types of batteries, you can make sure that there is no strong competition between them. Although the lithium-ion battery is thinner and sleeker, lithium-ion batteries have a higher specific energy consumption, and then, they are much cheaper to manufacture.

Therefore, do not pay special attention to the type of battery, just choose a branded portable charger that meets your requirements. After all, a lot of chemicals are added to these batteries, so it’s not yet known which ones will last longer.

When reading the “operating tips” for batteries on forums, one wonders whether people skipped physics and chemistry at school, or think that the rules for using lead and ion batteries are the same.

Let's start with the principles of the Li-Ion battery. On the fingers, everything is extremely simple - there is a negative electrode (usually made of copper), there is a positive one (made of aluminum), between them there is a porous substance (separator) saturated with electrolyte (it prevents “unauthorized” transition of lithium ions between the electrodes):

The principle of operation is based on the ability of lithium ions to integrate into the crystal lattice of various materials - usually graphite or silicon oxide - with the formation of chemical bonds: accordingly, when charging, ions are embedded in the crystal lattice, thereby accumulating charge on one electrode, when discharged, they transfer back to another electrode giving away the electron we need (who are interested in a more accurate explanation of the processes taking place - google intercalation). As the electrolyte, aqueous solutions are used that do not contain a free proton and are stable in a wide voltage range. As you can see in modern batteries, everything is done quite safely - there is no metallic lithium, there is nothing to explode, only ions run along the separator.

Now that everything has become more or less clear with the operating principle, let's move on to the most common myths about Li-Ion batteries:

- The first myth. The Li-Ion battery in the device cannot be discharged to zero percent.

In fact, everything sounds right and is consistent with physics - when discharged to ~ 2.5 V, the Li-Ion battery starts to degrade very quickly, and even one such discharge can significantly (up to 10%!) Reduce its capacity. In addition, when discharging to such a voltage with a standard charger, it will not be possible to charge it - if the battery cell voltage drops below ~ 3 V, the "smart" controller will turn it off as damaged, and if such cells are all, the battery can be carried to the trash.

But there is one very important thing that everyone forgets about: in phones, tablets and other mobile devices, the working voltage range on the battery is 3.5-4.2 V. When the voltage drops below 3.5 V, the indicator shows zero percent of the charge and the device turns off, but until critical "2.5 V is still very far away. This is confirmed by the fact that if you connect an LED to such a "discharged" battery, it can light up for a long time (maybe someone remembers that phones with flashlights that were turned on by a button regardless of the system were sold before. So, there the lamp continued to burn even after discharge and turn off the phone). That is, as you can see, with regular use of the discharge up to 2.5 V does not occur, which means it is quite possible to discharge Akum to zero percent. - The second myth. If Li-Ion is damaged, the batteries explode.

We all remember the “explosive” Samsung Galaxy Note 7. However, this is rather the exception to the rule - yes, lithium is a very active metal, and it is not difficult to detonate it in the air (and it burns very brightly in water). However, modern batteries use not lithium, but its ions, which are much less active. So in order for an explosion to occur, you need to try hard - either damage the charging battery physically (arrange a short circuit), or charge it with a very high voltage (then it will be damaged itself, but most likely the controller will burn down itself and prevent the battery from charging). Therefore, if you suddenly have a damaged or smoking battery in your hands - don’t throw it on the table and run away from the room shouting “we will all die” - just put it in a metal container and take it to the balcony (so as not to breathe chemistry) - the battery will smolder for a while and then go out. The main thing is not to flood with water, the ions are certainly less active than lithium, but still a certain amount of hydrogen will also be released during the reaction with water (and he likes to explode). - The third myth. When the Li-Ion battery reaches 300 (500/700/1000/100500) cycles, it becomes unsafe and needs to be changed urgently.

The myth, fortunately, is walking less and less on forums and having no physical or chemical explanation at all. Yes, during operation, the electrodes are oxidized and corroded, which reduces the battery capacity, but this does not threaten you with anything other than shorter battery life and unstable behavior. - The fourth myth. Li-Ion batteries cannot be used in cold weather.

This is more a recommendation than a ban. Many manufacturers prohibit the use of phones at freezing temperatures, and many have come across a quick discharge and generally disconnecting phones in the cold. The explanation for this is very simple: the electrolyte is a water-containing gel, and everyone knows what happens to water at low temperatures (yes, it freezes if that), thereby taking some area of \u200b\u200bthe battery out of work. This leads to a voltage drop, and the controller begins to consider this a discharge. The battery is not useful, but not fatal (after heating, the capacity will return), so if you desperately need to use the phone in cold weather (use it just out of a warm pocket, look at the time and hide it back) it’s better to charge it 100% and turn on any process that loads the processor - so cooling will occur more slowly. - The fifth myth. A swollen Li-Ion battery is dangerous and needs to be disposed of urgently.

This is not quite a myth, rather a precaution - a swollen battery can burst corny. From a chemical point of view, everything is simple: during the intercalation process, the electrodes and electrolyte decompose, resulting in gas evolution (it can also be released during recharging, but more on that below). But it is allocated very little, and for the battery to seem bloated, several hundred (if not thousands) of recharge cycles (unless of course it is defective) must pass. There are no problems getting rid of the gas - just pierce the valve (in some batteries it opens at excess pressure) and release it (I do not recommend breathing to them), after which you can cover the hole with epoxy. Of course, this battery will not return to its former capacity, but at least now it certainly will not burst. - The sixth myth. Li-ion batteries are harmful overcharge.

But this is no longer a myth, but a harsh reality - when recharging, there is a good chance that the battery will swell, burst and light up - believe me, there is little pleasure in being splattered with boiling electrolyte. Therefore, in all batteries there are controllers that are corny not allowing you to charge the battery above a certain voltage. But here you must be extremely careful in choosing a battery - controllers of Chinese crafts can often fail, and I don’t think you will be happy with the fireworks from the phone at 3 a.m. Of course, the same problem exists in branded batteries, but firstly, this happens much less often, and secondly, the entire phone will be changed under warranty. Usually this myth generates the following: - The seventh myth. Upon reaching 100%, you need to remove the phone from charging.

From the sixth myth, this seems reasonable, but in fact it makes no sense to get up in the middle of the night and remove the device from charging: firstly, controller malfunctions are extremely rare, and secondly, even when reaching 100% on the indicator, the battery is recharged for some time to the very maximum low currents, which adds another 1-3% capacity. So in fact, do not be so reinsured. - Myth eight. You can charge the device only with the original charger.

The myth takes place due to the poor quality of Chinese chargers - at a normal voltage of 5 + - 5% volts, they can give out both 6 and 7 - the controller, of course, will smooth out such voltage for some time, but in the future it will in the best case to the combustion of the controller, at worst - to the explosion and (or) failure of the motherboard. The opposite also happens - under load, the Chinese charger gives out 3-4 volts: this will lead to the fact that the battery will not be able to fully charge.

The processes of charging the discharge of any rechargeable batteries proceed in the form of a chemical reaction. However, the charge of lithium-ion batteries is an exception to the rule. Scientific studies show the energetics of batteries such as the chaotic movement of ions. The allegations of pundits deserve attention. If lithium-ion batteries are properly charged in science, then these devices should last forever.

Scientists see the facts of loss of useful capacity of batteries in practice as ions blocked by so-called traps.

Therefore, as in the case with other similar systems, lithium-ion devices are not immune from defects in the process of their application in practice.

Chargers for Li-ion structures have some similarities with devices designed for acid-lead systems.

But the main differences between such chargers are seen in the supply of high voltages to the cells. In addition, more stringent current tolerances are noted, plus the exclusion of charge in an intermittent or floating manner when the battery is fully charged.

A relatively powerful power device that can be used as an energy storage device for the construction of alternative energy sources

A relatively powerful power device that can be used as an energy storage device for the construction of alternative energy sources If they differ in some flexibility, in terms of voltage connection / disconnection, manufacturers of lithium-ion systems categorically reject this approach.

Li-ion batteries and the operating rules of these devices do not allow the possibility of unlimited overcharging.

Therefore, there is no so-called “miraculous” charger for lithium-ion batteries that can extend the life of the battery for a long time.

It is impossible to get additional Li-ion capacity due to a pulsed charge or other known tricks. Lithium-ion energy is a kind of “clean” system that takes a strictly limited amount of energy.

Charging cobalt-blended batteries

The classic designs of lithium-ion batteries are equipped with cathodes, the structure of which is made up of materials:

- cobalt,

- nickel,

- manganese,

- aluminum.

All of them are usually charged up to 4.20 V / I. The permissible deviation is not more than +/- 50 mV / i. But there are also certain types of nickel-based lithium-ion batteries that allow a charge of up to 4.10V / i.

Cobalt-blended lithium-ion batteries are equipped with internal protective circuits, but this point rarely saves the battery from exploding in overcharge mode

Cobalt-blended lithium-ion batteries are equipped with internal protective circuits, but this point rarely saves the battery from exploding in overcharge mode There is also a development of lithium-ion batteries, where the percentage of lithium is increased. For them, the charge voltage can reach a value of 4.30 V / I and above.

Well, an increase in voltage increases the capacitance, but voltage output beyond the specification is fraught with destruction of the battery structure.

Therefore, for the most part, lithium-ion batteries are equipped with protective circuits, the purpose of which is to maintain the established norm.

Full or partial charge

However, practice shows: most powerful lithium-ion batteries can take a higher voltage level if it is supplied for a short time.

With this option, the charging efficiency is about 99%, and the cell remains cold during the entire charge time. True, some lithium-ion batteries still heat up at 4-5C when they reach full charge.

Perhaps this is due to protection or due to high internal resistance. For such batteries, the charge should be stopped when the temperature rises above 10ºC at a moderate charge rate.

Li-ion batteries in the charger on charging. The indicator shows the full charge of the batteries. Further process threatens to damage batteries

Li-ion batteries in the charger on charging. The indicator shows the full charge of the batteries. Further process threatens to damage batteries Full charging of cobalt-blended systems occurs with a threshold voltage value. In this case, the current drops by up to 3 -5% of the nominal value.

The battery will show a full charge and when a certain level of capacity is reached, remaining unchanged for a long time. The reason for this may be increased self-discharge of the battery.

Increase charge current and saturation charge

It should be noted: an increase in the charge current does not accelerate the achievement of a state of full charge. Lithium- reaches the peak voltage faster, but the charge until the tank is fully saturated takes longer. However, charging the battery with high current quickly increases the battery capacity to about 70%.

Lithium-ion batteries do not support mandatory full charge, as is the case with lead-acid devices. Moreover, just such a charging option is undesirable for Li-ion. In fact, it is better not to fully charge the battery, because high voltage “strains” the battery.

The choice of a lower voltage threshold or full removal of the saturation charge helps to extend the life of the lithium-ion battery. True, this approach is accompanied by a decrease in the time of the return of battery energy.

It should be noted here: household chargers, as a rule, operate at maximum power and do not support charging current (voltage) adjustments.

Manufacturers of household chargers for lithium-ion batteries consider the long life less important than the cost of complicating circuit designs.

Li-ion Battery Chargers

Some cheap home chargers often use a simplified technique. Charge a lithium-ion battery for one hour or less, without switching to a saturation charge.

The ready indicator on such devices lights up when the battery reaches the voltage threshold in the first stage. The state of charge in this case is about 85%, which often satisfies many users.

This domestic charger is offered for use with various batteries, including lithium-ion batteries. The device has a voltage and current regulation system, which is already good

This domestic charger is offered for use with various batteries, including lithium-ion batteries. The device has a voltage and current regulation system, which is already good Professional chargers (expensive) are characterized in that they set the threshold of the charging voltage lower, thereby extending the life of the lithium-ion battery.

The table shows the calculated power when charging such devices at different threshold voltage values, with and without saturation charge:

| Charge voltage, V / per cell | Capacity at high voltage cutoff,% | Charge time, min | Capacity at full saturation,% |

| 3.80 | 60 | 120 | 65 |

| 3.90 | 70 | 135 | 75 |

| 4.00 | 75 | 150 | 80 |

| 4.10 | 80 | 165 | 90 |

| 4.20 | 85 | 180 | 100 |

As soon as the lithium-ion battery begins to charge, a rapid increase in voltage is noted. This behavior is comparable to lifting a load with a rubber band when there is a lag effect.

The capacity will eventually be full when the battery is fully charged. This charge characteristic is typical for all batteries.

The higher the charge current, the brighter the effect of the rubber tape. Low temperature or the presence of a cell with high internal resistance only enhance the effect.

The structure of a lithium-ion battery in its simplest form: 1- minus copper bus; 2 - positive tire made of aluminum; 3 - anode of cobalt oxide; 4- cathode made of graphite; 5 - electrolyte

The structure of a lithium-ion battery in its simplest form: 1- minus copper bus; 2 - positive tire made of aluminum; 3 - anode of cobalt oxide; 4- cathode made of graphite; 5 - electrolyte Assessing the state of charge by reading the voltage of a charged battery is impractical. An open circuit voltage measurement (idle) after the battery has been idle for several hours is the best indicator.

As with other batteries, temperature affects idle in the same way that it affects the active material of a lithium-ion battery. , laptops and other devices is estimated by counting pendants.

Lithium-ion battery: saturation threshold

The lithium-ion battery is not capable of absorbing excess charge. Therefore, when the battery is fully saturated, the charge current must be removed immediately.

A constant current charge can lead to metallization of lithium cells, which violates the principle of ensuring the safe operation of such batteries.

To minimize defect formation, you should disconnect the lithium-ion battery as soon as possible when the charge peak is reached.

This battery will not take charge as much as it should. Due to improper charging, he lost his main energy storage properties.

This battery will not take charge as much as it should. Due to improper charging, he lost his main energy storage properties. As soon as the charge stops, the voltage of the lithium-ion battery begins to drop. The effect of reducing physical stress is manifested.

For some time, the open circuit voltage will be distributed between unevenly charged cells with a voltage of 3.70 V and 3.90 V.

Here, the process is also noteworthy when a lithium-ion battery, which has received a fully saturated charge, begins to charge the neighboring battery (if one is included in the circuit), which has not received a saturation charge.

When lithium-ion batteries are required to be constantly kept in the charger in order to ensure their readiness, bet on chargers that have the function of short-term compensation charge.

The charger with the function of short-term compensation charge turns on if the open circuit voltage drops to 4.05 V / I and turns off when the voltage reaches 4.20 V / I.

Chargers designed for operational readiness or for standby mode often allow you to lower the battery voltage to 4.00V / i and charge lithium-ion batteries only to 4.05V / i, preventing them from reaching the full level of 4.20V / i.

Such a technique reduces physical stress, inherently related to technical stress, and helps to extend battery life.

Charge without cobalt batteries

Traditional batteries have a nominal cell voltage of 3.60 volts. However, for devices that do not contain cobalt, the denomination is different.

So, lithium-phosphate batteries have a nominal value of 3.20 volts (charging voltage of 3.65V). And the new lithium-titanate batteries (made in Russia) have a nominal cell voltage of 2.40V (charging 2.85).

Lithium phosphate batteries are energy storage devices that do not contain cobalt in their structure. This fact slightly changes the charging conditions of such batteries.

Lithium phosphate batteries are energy storage devices that do not contain cobalt in their structure. This fact slightly changes the charging conditions of such batteries. For such batteries, traditional chargers are not suitable, as they overload the battery with a risk of explosion. Conversely, a charging system for cobalt-free batteries will not provide a sufficient 3.60V charge for a traditional lithium-ion battery.

Excessive Li-ion Battery

The lithium-ion battery operates safely within specified operating voltages. However, the operation of the battery becomes unstable if it is charged above operating standards.

Long-term charging of a lithium-ion battery with a voltage above 4.30V, designed for a working rating of 4.20V, is fraught with metallization of the anode with lithium.

The cathode material, in turn, acquires the properties of an oxidizing agent, loses state stability, and emits carbon dioxide.

The pressure of the battery cell increases and if the charge continues, the internal protection device will operate at a pressure of 1000 kPa to 3180 kPa.

If the pressure increase continues even after this, the protective membrane opens at a pressure level of 3.450 kPa. In this state, the cell of the lithium-ion battery is on the verge of explosion and ultimately this is exactly what happens.

Structure: 1 - top cover; 2 - upper insulator; 3 - steel can; 4 - lower insulator; 5 - anode tab; 6 - cathode; 7 - separator; 8 - anode; 9 - cathode tab; 10 - outlet; 11 - PTC; 12 - gasket

Structure: 1 - top cover; 2 - upper insulator; 3 - steel can; 4 - lower insulator; 5 - anode tab; 6 - cathode; 7 - separator; 8 - anode; 9 - cathode tab; 10 - outlet; 11 - PTC; 12 - gasket The operation of the protection inside the lithium-ion battery is associated with an increase in the temperature of the internal contents. A fully charged battery has a higher internal temperature than a partially charged battery.

Therefore, lithium-ion batteries are seen to be safer on the condition of low-level charging. That is why the authorities of some countries require the use of Li-ion batteries in aircraft, saturated with energy not exceeding 30% of their full capacity.

The threshold of the internal temperature of the batteries when fully loaded is:

- 130-150 ° C (for lithium-cobalt);

- 170-180 ° C (for nickel-manganese-cobalt);

- 230-250 ° C (for lithium manganese).

It should be noted: lithium-phosphate batteries have better temperature stability than lithium-manganese batteries. Lithium-ion batteries are not the only ones that pose a danger in conditions of energy overload.

For example, lead-nickel batteries are also prone to melting, followed by fire, if energy saturation is performed with violations of the passport regime.

Therefore, the use of chargers ideally suited to the battery is of paramount importance for all lithium-ion batteries.

Some conclusions from the analysis

Charging lithium-ion batteries has a simplified technique compared to nickel systems. The charging circuit is straightforward, with voltage and current limitations.

Such a circuit is much simpler than a circuit that analyzes complex voltage signatures that change as the battery is used.

The process of saturation of lithium-ion batteries with energy is interruptible; these batteries do not need to be fully saturated, as is the case with acid-lead batteries.

Controller circuit for low power lithium-ion batteries. A simple solution and a minimum of details. But the circuit does not provide cycle conditions under which a long service life is maintained.

Controller circuit for low power lithium-ion batteries. A simple solution and a minimum of details. But the circuit does not provide cycle conditions under which a long service life is maintained. The properties of lithium-ion batteries promise the benefits of a renewable energy source (solar panels and wind turbines). As a rule, either a wind generator rarely provides a full battery charge.

For a lithium-ion, the lack of stable charging requirements simplifies the charge controller circuit. The lithium-ion battery does not require a controller that balances voltage and current, as required by lead-acid batteries.

All household and most industrial lithium-ion chargers fully charge the battery. However, the existing devices for charging lithium-ion batteries for the most part do not provide voltage regulation at the end of the cycle.