1. What is the LED made of?From a semiconductor crystal on a substrate, a package with contact pins and an optical system. Modern LEDs bear little resemblance to the first box-type LEDs used for indication. The construction of a high-power LED is shown schematically in the figure. 2. How does the LED work?The glow arises from the recombination of electrons and holes in the pn junction region. So, first of all, a p-n junction is needed, that is, the contact of two semiconductors with different types of conductivity. To do this, the near-contact layers of a semiconductor crystal are doped with different impurities: acceptor on one side, donor on the other, but not every pn junction emits light. Why? Firstly, the band gap in the active region of the LED should be close to the energy of quanta of light in the visible range. Secondly, the radiation probability during recombination of electron-hole pairs should be high, for which the semiconductor crystal should contain few defects, due to for which recombination occurs without radiation. These conditions, to one degree or another, contradict each other. In reality, in order to meet both conditions, one pn-junction in the crystal is not enough, and it is necessary to produce multilayer semiconductor structures, the so-called heterostructures, for the study of which the Russian physicist Academician Zhores Alferov received the 2000 Nobel Prize. 3. Does this mean that the more current flows through the LED, the brighter it shines?Of course, yes. After all, the greater the current, the more electrons and holes enter the recombination zone per unit time. But the current cannot be increased indefinitely. Due to the internal resistance of the semiconductor and the pn junction, the diode will overheat and fail. 4. Why is LED good?In an LED, unlike an incandescent lamp or fluorescent lamp, the electric current is converted directly into light radiation, and in theory this can be done with almost no loss. Indeed, the LED (with proper heat dissipation) heats up little, which makes it indispensable for some applications. Further, the LED emits in a narrow part of the spectrum, its color is clear, which is especially appreciated by designers, and UV and IR radiation are usually absent. The LED is mechanically strong and extremely reliable, its service life reaches 100 thousand hours, which is almost 100 times more than an incandescent light bulb, and 5 to 10 times more than a fluorescent lamp. Finally, an LED is a low-voltage electrical device, and therefore, safe. 5. When did LEDs begin to be used for lighting?Initially, LEDs were used exclusively for indication. To make them suitable for lighting, it was necessary first of all to learn how to make white LEDs, as well as to increase their brightness, or rather luminous efficiency, that is, the ratio of luminous flux to energy consumption. In the 60s and 70s, LEDs based on phosphide were created. and gallium arsenide, emitting in the yellow-green, yellow and red regions of the spectrum. They were used in light indicators, boards, dashboards of cars and aircraft, advertising screens, and various information visualization systems. In terms of light output, LEDs have outperformed conventional incandescent lamps. They also surpassed them in terms of durability, reliability, safety. One thing was bad - there were no blue, blue-green and white LEDs. By the end of the 80s, more than 100 million LEDs were produced in the USSR a year, and the world production was several tens of billions. 6. What does the LED color depend on?Exclusively from the band gap in which electrons and holes recombine, that is, from the semiconductor material, and from dopants. The “blue” the LED, the higher the energy of the quanta, which means that the larger the band gap must be. 7. What is LED quantum output?Quantum yield is the number of emitted light quanta per recombined electron-hole pair. Distinguish between internal and external quantum efficiency. Internal - in the pn-junction itself, external - for the device as a whole (after all, light can be lost "along the way" - absorbed, scattered). The internal quantum efficiency for good crystals with good heat dissipation reaches almost 100%, The external quantum efficiency record for red LEDs is 55%, and for blue LEDs it is 35%. External quantum efficiency is one of the main characteristics of LED efficiency. 8. How to get white light using LEDs?There are three ways to get white light from LEDs, the first is by mixing colors using RGB technology. One matrix densely accommodates red, blue and green LEDs, the radiation of which is mixed using an optical system, such as a lens. The result is white light. The second method consists in the fact that three phosphors emitting blue, green and red light, respectively, are applied to the surface of an LED emitting in the ultraviolet range (there are some). This is similar to how a fluorescent lamp shines. And finally, in the third method, yellow-green or green plus red phosphor is applied to a blue LED, so that two or three radiations are mixed to form white or near-white light. 9. Which of the three is the best way?Each method has its own advantages and disadvantages. RGB technology, in principle, allows not only to obtain white color, but also to move along the color chart when the current through different LEDs changes. This process can be controlled manually or by means of a program, it is also possible to obtain different color temperatures. Therefore, RGB matrices are widely used in dynamic lighting systems. In addition, a large number of LEDs in the matrix provide a high total luminous flux and high axial luminous intensity. But the light spot due to the aberrations of the optical system has an uneven color in the center and at the edges, and most importantly, due to uneven heat removal from the edges of the matrix and from its middle, the LEDs heat up differently, and, accordingly, their color changes differently. in the process of aging - the total color temperature and color "float" during the operation. This unpleasant phenomenon is difficult and expensive to compensate for. White LEDs with phosphors are significantly cheaper than RGB LED matrices (per unit of luminous flux), and allow you to get good white color. And for them, in principle, it is not a problem to get to a point with coordinates (0.33, 0.33) on the MCO color diagram. The disadvantages are as follows: first, they have less light output than RGB matrices because of the transformation of light in the phosphor layer; secondly, it is rather difficult to accurately control the uniformity of the phosphor deposition in technological process and therefore the color temperature; and finally thirdly - the phosphor also ages, and faster than the LED itself. The industry produces both LEDs with a phosphor and RGB matrices - they have different areas of application. 10. What are the electrical and optical characteristics of LEDs?The LED is a low voltage device. A typical LED used for indication consumes from 2 to 4 VDC at a current of up to 50 mA. The LED used for lighting consumes the same voltage, but the current is higher - from several hundred mA to 1 A in the project. In the LED module, individual LEDs can be connected in series and the total voltage turns out to be higher (usually 12 or 24 V). When connecting the LED, the polarity must be observed, otherwise the device may be damaged. The breakdown voltage is specified by the manufacturer and is usually greater than 5 V per LED. The brightness of an LED is characterized by the luminous flux and axial luminous intensity, as well as the directional pattern. Existing LEDs of various designs emit at a solid angle of 4 to 140 degrees. Color, as usual, is determined by chromaticity coordinates and color temperature, as well as the wavelength of the radiation. To compare the efficiency of LEDs with each other and with other light sources, light output is used: the amount of luminous flux per watt of electrical power. Also, an interesting marketing characteristic is the price of one lumen. 11. How does the LED respond to a rise in temperature?Speaking about the temperature of the LED, it is necessary to distinguish between the temperature on the surface of the crystal and in the region of the pn junction. The service life depends on the first, the light output depends on the second. In general, with an increase in the pn junction temperature, the brightness of the LED decreases, because the internal quantum yield decreases due to the influence of crystal lattice vibrations. That's why good heat dissipation is so important. The drop in brightness with increasing temperature is not the same for LEDs. different colors... It is higher for AlGalnP and AeGaAs LEDs, that is, for red and yellow, and less for InGaN, that is, for green, blue and white. 12. Why is it necessary to stabilize the current through the LED?As can be seen from the figure, in operating modes, the current exponentially depends on the voltage and small changes in voltage lead to large changes in current. Since the light output is directly proportional to the current, the brightness of the LED is also unstable. Therefore, the current must be stabilized. In addition, if the current exceeds the permissible limit, then overheating of the LED can lead to its accelerated aging. typical volt-ampere characteristics LED 13. Why does the LED need a converter?A converter (in English terminology, driver) for an LED is the same as ballast for a lamp. It stabilizes the current flowing through the LED. 14. Can the brightness of the LED be adjusted?The brightness of the LEDs lends itself very well to regulation, but not by reducing the supply voltage - this just cannot be done - but by the so-called pulse-width modulation (PWM) method, which requires a special control unit (in fact, it can be combined with a unit power supply and a converter, as well as with an RGB matrix color control controller) .The PWM method consists in the fact that the LED is supplied not with a constant, but with a pulse-modulated current, and the signal frequency should be hundreds or thousands of hertz, and the width of the pulses and pauses between them can be changed. The average brightness of the LED becomes controllable, while the LED does not go out. The slight change in color temperature of an LED during dimming is incomparable to the same offset for incandescent lamps. 15. What determines the lifespan of an LED?LEDs are believed to be extremely durable. But it is not so. The more current is passed through the LED during its service, the higher its temperature and the faster aging occurs. Therefore, the service life of high-power LEDs is shorter than that of low-power signal LEDs, and currently amounts to 20 - 100 thousand hours. Aging is expressed primarily in a decrease in brightness. When the brightness is reduced by 30% or half, the LED must be changed. 16. Does the color of the LED deteriorate over time?The aging of an LED is associated not only with a decrease in its brightness, but also with a change in color. There are currently no standards that would quantify the color change of LEDs with aging and compare with other sources. 17. Is the LED harmful to the human eye?The emission spectrum of an LED is close to monochromatic, which is its fundamental difference from the spectrum of the sun or an incandescent lamp. 18. What technologies are available for manufacturing LEDs and LED modules today?As for growing crystals, the main technology is organometallic epitaxy. This process requires highly pure gases. Modern installations provide for automation and control of the composition of gases, their separate flows, precise control of the temperature of gases and substrates. The thickness of the grown layers is measured and controlled in the range from tens of angstroms to several microns. Different layers must be doped with impurities, donors or acceptors in order to create a p-n junction with a high concentration of electrons in the n-region and holes in the p-region. In one process, which lasts several hours, it is possible to grow structures on 6 - 12 substrates with a diameter of 50 - 75 mm. It is very important to ensure and control the uniformity of structures on the surface of the substrates. The cost of installations for the epitaxial growth of semiconductor nitrides, developed in Europe (Aixtron and Thomas Swan) and the USA (Emcore), reaches 1.5-2 million dollars. The experience of different companies has shown that it is possible to learn how to obtain competitive structures with the required parameters using such a facility in a time from one to three years. This is a technology that requires a high level of culture. An important stage of the technology is the planar processing of the films: their etching, the creation of contacts to the n- and p-layers, and the coating with metal films for the contact leads. The film grown on a single substrate can be cut into several thousand chips ranging in size from 0.24x0.24 to 1x1 mm2. The next step is to create LEDs from these chips. It is necessary to mount the crystal in the case, make contact leads, make optical coatings, antireflection surface for radiation output or reflecting it. If it is a white LED, then the phosphor must be applied evenly. It is necessary to provide heat dissipation from the crystal and case, to make a plastic dome that focuses the radiation into the desired solid angle. About half of the cost of an LED is determined by these stages of high technology. The need to increase the power to increase the luminous flux led to the fact that the traditional form of the package LED has ceased to satisfy manufacturers due to insufficient heat dissipation. It was necessary to bring the chip as close as possible to the heat-conducting surface. In this regard, the traditional technology and somewhat more advanced SMD technology (surface montage details) is being replaced by the most advanced technology COB (chip on board). The LED made using the COB technology is shown schematically in the figure. The LEDs made using the SMD and COB technology are mounted (glued) directly onto a common substrate, which can act as a radiator - in this case, it is made of metal. This is how LED modules are created, which can be linear, rectangular or circular, rigid or flexible, in short, designed to satisfy any designer's whim. LED lamps with the same base as low-voltage halogen lamps appear, designed to replace them. And for high-power luminaires and spotlights, LED assemblies are made on a round massive radiator. There used to be a lot of LEDs in LED assemblies, but now, as the power increases, there are fewer LEDs, but the optical system, directing the light flux to the desired solid angle, plays an increasingly important role.

iDS technologyArticle source: OOO "Focus"

LED Graphic designation ![]()

A light emitting diode (LED) is a semiconductor light source. LEDs are used as indicators in many devices and are increasingly used for lighting purposes. It was developed as an electronic component suitable for practical use in 1962. The first samples emitted low intensity red light, but modern versions emit very high brightness in the entire visible, ultraviolet and infrared regions of the spectrum.

The LED is designed on the basis of a semiconductor diode. When the operating voltage is applied to the diode, the electrons with holes swap places, releasing energy in the form of photons. This effect is called electroluminescence and the color of light (corresponds to the photon energy) is determined by the energy of the semiconductor's band gap. LED crystals, as a rule, are small in area (less than 1 mm2), the light distribution pattern and the reflection index are formed by an additional optical system included in the LED design. LEDs have many advantages over incandescent bulbs and other light sources, including lower power consumption, longer lifespan, increased reliability, smaller size, faster turn-on, and greater durability. However, they are quite expensive and have higher power and heat dissipation requirements compared to traditional light sources. Current LED general lighting products are more expensive than comparable fluorescent sources.

LEDs are increasingly used in automotive electronics as direction indicators, side lights and brake lights. LED traffic lights are already a common way to regulate traffic. The compact size of LEDs allows the development of new types of displays and screens, and their high switching speed is beneficial in advanced communication technologies.

Invention and first samples

The electroluminescence of a silicon carbide crystal (green) was discovered in 1907 by the English scientist Round in the Marconi laboratory. This phenomenon was then ignored. In 1923, the Soviet scientist O.V. Losev, working at the NRL (Nizhny Novgorod Radio Laboratory), carried out in-depth studies of such a phenomenon as radiative recombination, and also observed the emission of light emanating from crystals of silicon carbide SiC (carborundum). Long-term studies have made it possible to formulate the main principle of electroluminescence of semiconductor structures - injection recombination. In 1927 Losev patented the principle of semiconductor luminescence. The invention was published in Russian, German and English scientific journals, but did not receive practical application. In 1955, R. Braunstein of the Radio Corporation of America announced the presence of infrared radiation of gallium arsenide (GaAs) in combination with other semiconductor alloys. Braunstein observed infrared radiation generated by a simple diode structure based on gallium antimonide (GaSb), gallium arsenide, indium phosphide (InP), and silicon-germanium alloy (SiGe) at room temperature.In 1961, developers R. Bard and G. Pitman at Texas Instruments discovered that gallium arsenide alloy produces infrared radiation when passed through it. electric current and received a patent for IR LED.

The first LED, emitting light in the visible spectrum, was invented in 1962 by N. Holonyak, who works for General Electric. Since then, many have called him the "father" of modern LEDs. To understand that this is not so, it is enough to study the historical information about the research of O. V. Losev and other eminent scientists of 20-50. twentieth century. However, history is not fair, and we have what we have, and in the 60s Russia lost its priority in the invention of semiconductor light sources.

In 1972, former Holonyak student G. Graford invented the yellow LED and increased the brightness of red and red-orange LEDs tenfold. In 1976, T. Pearsell created the first super-bright LED for optical fiber telecommunications, inventing new semiconductor alloys specially adapted for transmitting light through optical fibers.

Until 1968, visible and infrared LEDs had a huge production cost, about 200 USD apiece, which created difficulties for practical use. But in 1968, Monsanto pioneered the mass production of gallium arsenide phosphide (GaAsP) -based visible light LEDs, suitable for use as indicators. Hewlett Paccard, which introduced LEDs in 1968, used Monsanto LEDs to produce digital displays and calculators.

Practical use of the first LEDs

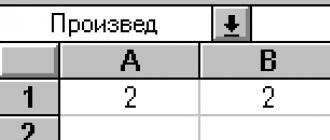

The first commercial use of LEDs was associated with their use as a replacement for indicators previously based on the use of incandescent lamps. Seven-segment indicators were made from LEDs, built into expensive laboratory instruments, used in test equipment, but later LEDs began to be used in the manufacture of televisions, radios, telephones, calculators and even watches. Red LEDs used for these purposes had a brightness sufficient for use only as indicators. LEDs of other colors were even less bright. All types of led were produced in standard sizes 3 or 5 mm.Further development of LED technology

The first super-bright blue LEDs based on InGaN were demonstrated by Sh. Nakamura from the Japanese company Nichia. This marked the beginning of a new era in the use of LEDs - the use as a light source for lighting. The combination of blue light and yellow phosphorus produced white light.Thanks to this discovery, LED technology began to develop rapidly. In February 2008, employees at Bilkent University in Turkey announced they were receiving 300 lumens of visible light per watt of light output. It was a warm white using nanocrystals.

In January 2009, researchers from Cambridge, led by S. Humphrey, reported on the growth of gallium nitride on a silicon substrate. This method can reduce production costs in the production of ultrabright LEDs by 90% compared to the growth of structures on a sapphire substrate.

Physical aspects

How the LED works

Like a regular diode, an LED contains semiconductor crystals that create a pn junction. As with a conventional diode, the current easily flows in the forward direction from the anode to the cathode and does not flow in the opposite direction. When electrons meet holes, they lose energy, which is converted into photons. The wavelength at which photons are emitted depends on the material forming the pn junction.

The invention of LEDs began with the fabrication of gallium arsenide structures that emit red and infrared light. The current development of semiconductor technology allows visible light to be produced in a wide variety of colors.

Electrons and holes

Semiconductors are intermediate between conductors and insulators (dielectrics). At low temperatures, most of the outer electrons in a semiconductor "sit" in the atoms in their places. But they are bound to atoms weaker than in an insulator. Moreover, with an increase in temperature, the resistance of semiconductors decreases, that is, a semiconductor when heated does not reduce its electrical conductivity, like a metal, but, on the contrary, increases it. In other words, the number of free electrons capable of carrying electric current increases in a semiconductor.

When energy (heat or light) is supplied to the crystal lattices of semiconductors, some of the electrons "run away" from the upper atomic shells, and a positive charge is formed. The place where the electron is missing in the lattice is called a "hole".

Under the action of an electric voltage, electrons drift to one electrode (positive pole), and holes - to another (negative), and their place is immediately taken by free electrons. The laws of motion of holes are such that physicists conditionally ascribe both a charge (equal to the charge of an electron, but positive) and an "effective mass" to these "empty spaces".

In a pure semiconductor, the conductivity of which is due to thermal excitation, the same number of electrons and holes move in opposite directions. If atoms of other elements are added to the semiconductor, its conductivity can be significantly increased. When dopants are introduced into various parts of the crystal lattice of a semiconductor, the so-called impurity conductivity (as opposed to intrinsic conductivity) arises, which, depending on the valence of the doping elements, is called either electronic (n-type conductivity) or hole (p-type).

In the same sample of semiconductor material, one section may have p-conductivity, and the other - n-conductivity. A boundary layer arises between such regions through which the majority carriers (electrons or holes) diffuse, seeking to equalize the concentration values \u200b\u200bon both sides of the layer. The pn junction formed in this layer can be acted upon by an external voltage, amplifying or, conversely, "blocking" the current passing through the crystal - on the basis of this principle, diodes and transistors operate. With positive polarity external stress (plus - to the p-band, minus - to the n-band) the barrier in the p-n-junction decreases, and "jumping" (recombination) of electrons and holes into opposite bands occurs, as a result of which energy is released.

At first, semiconductor devices were only "homojunction" (as in the case of the first transistor) - the pn junction occurred inside the crystal of one chemical substance. But almost immediately, the idea of \u200b\u200bhetero-devices appeared, in which such a transition is formed at the junction of two different semiconductors. The implementation of this idea has made it possible to create smaller devices with greater efficiency and functionality (for example, the world's first "homojunction" semiconductor LEDs, and then lasers could operate only at the temperature of liquid nitrogen, and the heterojunction ones that appeared later function at room temperature).

Most of the materials used to make LEDs are highly reflective. This is necessary so that as much of the light produced by the LED as possible escapes from its surface outside the enclosure. That is why a large number of studies around the world are devoted to this.

Efficiency and use parameters

A conventional LED indicator is designed for a power of no more than 30-60 mW. In 1999 Philips Lumileds introduced a 1 Watt high power LED. In this LED, a semiconductor crystal was used with a much larger area than those used in conventional indicator type LEDs. It was mounted on a metal base, which made it possible to organize efficient heat removal from the crystal.One of the key positions in determining the efficiency of an LED is the light output per unit of power. White LED quickly reached and surpassed performance conventional systems based on incandescent lamps. In 2002, Lumileds produced a 5W LED with 18-22 lumen / Watt lumen output. In comparison, a typical 60-100W incandescent lamp produces about 15 lumens per watt. Fluorescent lamp - about 100 lm / W. The main problem in the development of high-power LEDs is the drop in luminous flux with increasing current passing through the crystal.

In September 2003, Cree demonstrated a new type of blue LED that produces 24 mW at 20 mA. This made it possible to commercialize white LEDs with an efficiency of 65 lm / W at a current of 20 mA, which became the brightest on the market at that time and exceeded the efficiency of incandescent lamps by more than four times. In 2006, the same company presented a prototype of a white LED with a light output of 131 lm / W at 20 mA.

It should be noted that LED power of 1 W or more is quite sufficient for commercial use as a source of primary lighting. Typical current of such LEDs is 350 mA. Although the leading manufacturers produce LEDs with an efficiency higher than 100 lm / W, in actual use, much depends on the operating conditions and the design of the luminaire. US Department of Energy, which conducted testing in 2008 lED lampscommercially available, provided data showing that most of these lamps have an average efficiency of 31 lm / W.

Cree provided data on a laboratory prototype LED with an efficiency of 161 lm / W at room temperature and a light temperature of 4689 K on November 19, 2008.

Faults and LED lifespan

Solid state devices such as LEDs are very susceptible to damage when operated at low temperatures and low currents. Many LEDs produced in the 70s and 80s are still in use today. In theory, LED performance is unlimited in time, however, increased current and high temperature can easily destroy them. The main symptom of a LED malfunction is a strong decrease in the light output at the nominal operating voltage. The development of new types of LEDs resulted in higher operating currents and an increase in crystal temperature. The reaction of materials from which high-power LEDs are made to such conditions has not yet been fully studied, therefore crystal degradation is one of the main causes of failures. An LED is considered inoperative when its light output drops by 75%.Materials

The following table shows the dependence of the LED light color on the semiconductor material| Colour | Wavelength (nm) | Voltage (V) | Semiconductor material | |

|---|---|---|---|---|

| Infrared | λ\u003e 760 | ΔV< 1.9 | Gallium arsenide (GaAs) Aluminum gallium arsenide (AlGaAs) |

|

| Red | 610 < λ < 760 | 1.63 < ΔV < 2.03 | Aluminum gallium arsenide (AlGaAs) |

|

| Orange | 590 < λ < 610 | 2.03 < ΔV < 2.10 | Gallium arsenide phosphide (GaAsP) Aluminum gallium indium phosphide (AlGaInP) Gallium (III) phosphide (GaP) |

|

| Yellow | 570 < λ < 590 | 2.10 < ΔV < 2.18 | Gallium arsenide phosphide (GaAsP) Aluminum gallium indium phosphide (AlGaInP) Gallium (III) phosphide (GaP) |

|

| Green | 500 < λ < 570 | 1.9 [ 32] < ΔV < 4.0 | Indium gallium nitride (InGaN) / Gallium (III) nitride (GaN) Gallium (III) phosphide (GaP) Aluminum gallium indium phosphide (AlGaInP) Aluminum gallium phosphide (AlGaP) |

|

| Blue | 450 < λ < 500 | 2.48 < ΔV < 3.7 | Zinc selenide (ZnSe) Indium gallium nitride (InGaN) Silicon carbide (SiC) as substrate Silicon (Si) as substrate - (under development) |

|

| Violet | 400 < λ < 450 | 2.76 < ΔV < 4.0 | Indium gallium nitride (InGaN) | |

| Purple | different types | 2.48 < ΔV < 3.7 | Dual blue / red LEDs, blue with red phosphorus, white with magenta filter |

|

| UV | λ < 400 | 3.1 < ΔV < 4.4 | diamond (235 nm) [33] Boron nitride (215 nm) [34] [35] Aluminum nitride (AlN) (210 nm) [36] Aluminum gallium nitride (AlGaN) Aluminum gallium indium nitride (AlGaInN) - (down to 210 nm) [37] |

|

| White | Wide range | ΔV \u003d 3.5 | Blue / UV diode and yellow phosphorus |

Blue LEDs

Blue LED

Blue LEDs are based on GaN and InGaN alloys. The combination with red and green LEDs produces pure white, but this principle of white formation is now rarely used.

The first blue LED was made in 1971 by Jacques Pankove (inventor of gallium nitride). But it produced too little light to be used in practice. The first bright blue diode was demonstrated in 1993 and gained widespread acceptance.

White light

There are two ways to get sufficient white light using LEDs. The first of them is the combination of crystals of three primary colors - red, blue and green - in one body. Mixing these colors produces white. Another way is to use a phosphor to convert blue or ultraviolet light into a broad spectrum white. A similar principle is used in the production of fluorescent lamps.RGB systems

White can be obtained by mixing different colors, the most commonly used combination being red, blue and green. But due to the need to control the mixing and the degree of color dispersion, the production cost of RGB LEDs is quite high. Nevertheless, this method is interesting to many researchers and scientists, as it allows you to get different shades of color. Moreover, the efficiency of this method for producing white light is very high.There are several types of multicolor white LEDs - di-, tri-, and tetrachromatic. There are some key features each of these types, including color stability, color rendering, and luminous efficiency. High luminous efficiency means a low color rendering index (CRI). For example, a dichromatic white LED has the best luminous efficacy (around 120 lm / W), but the lowest CRI. Tetrachromatic - low luminous efficacy but excellent CRI. Trichromatic is located approximately in the middle.

Although multicolor LEDs are not the best solution for achieving white color, their use can create systems that produce millions of different shades of color. The main problem with this is different meanings luminous efficiency for primary colors. As the temperature rises, this causes the required color to "float away" and, as a consequence, to more stringent requirements for power supply and control systems.

Phosphorus LEDs

The spectrum of a white LED is determined by blue light, which is emitted by a GaN-based crystal (peak in the region of 465 Nm) and, passing through yellow phosphorus (500-700 Nm), is converted to white. The use of different types and shades of phosphorus produces different shades of white - from the warmest to the coldest. The quality of color rendition also depends on this. The application of several layers of phosphorus of different types to the blue crystal allows achieving the highest CRI.Phosphorus-based LEDs are less efficient than conventional LEDs because some of the light is scattered in the phosphorus layer, and phosphorus itself is also subject to degradation. Nevertheless, this method remains the most popular in the commercial production of white LEDs. The most commonly used yellow phosphoric material is Ce3 +: YAG.

Also, white LEDs can be made on the basis of ultraviolet LEDs using red and blue phosphorus with the addition of zinc sulfide (ZnS: Cu, Al). This principle is similar to that used in fluorescent lamps. This method is worse than the previous one, but it allows you to achieve better color reproduction. In addition, UV diodes have a high luminous efficiency. On the other hand, UV radiation is harmful to humans.

Organic LEDs (OLED)

If the base of the emitting surface of the LED is organic in origin, such an LED is called OLED (Organic Light Emitting Diode). The emitting material can be a small molecule in the crystallization phase or a polymer. Polymer crystals can be flexible, respectively called PLED or FLED.Compared to conventional LEDs, OLEDs are lighter, and polymer also makes the light source flexible. In the future, on the basis of such LEDs, it is planned to manufacture flexible inexpensive displays for portable devices, light sources, decorative systems, and luminous clothing. But so far the level of OLED development does not allow their commercial use.

Quantum Dot LEDs (Experimental)

The new LED technology developed by M. Bowers involves coating a blue LED with "quantum dots", which begin to emit white light when exposed to blue light from the LED. This technology produces a warm, yellow-white light similar to incandescent light. "Quantum dots" are semiconductor nanocrystals with unique optical characteristics. Their radiation color can be changed over a wide range - from visible to invisible - any color within the CIE diagram.In September 2009, the Nanoco Group announced a research agreement with one of the largest Japanese companies. The topic of research is the further development of "quantum dot" technology for use in LCD television displays.

To be continued

Since the discovery of the red LED (1962), the development of solid-state light sources has not stopped for a moment. Each decade was marked by scientific advances and opened new horizons for scientists. In 1993, when Japanese scientists managed to obtain blue light, and then white, the development of LEDs switched to new level... Physicists all over the world faced a new challenge, the essence of which was to use LED lighting as the main one.

Nowadays, the first conclusions can be drawn indicating the success of the development of LED lighting and the ongoing modernization of the LED. Luminaires with LEDs manufactured using COB, COG, SMD, filament technologies appeared on store shelves.

How does each of the listed types work, and what physical processes force a semiconductor crystal to glow?

What is LED?

Before analyzing the device and the principle of operation, let's briefly consider what the LED is.

An LED is a semiconductor component with an electron-hole junction that emits optical radiation when an electric current is passed in the forward direction.

Unlike filaments and fluorescent light sources, the light emitted by an LED is in a small spectrum range. That is, the LED crystal emits a specific color (in the case of visible spectrum LEDs). To obtain a certain spectrum of radiation in LEDs, a special chemical composition of semiconductors and a phosphor is used.

Device, design and technological differences

There are many signs by which LEDs can be classified into groups. One of them is the technological difference and the slight difference in the device, which is caused by the peculiarity of the electrical parameters and the future field of application of the LED.

DIP

The cylindrical, double-ended epoxy housing was the first design for a light emitting crystal. A rounded colored or transparent cylinder serves as a lens, forming a directed beam of light. The pins are inserted into holes in the printed circuit board (DIP) and soldered to provide electrical contact.

The emitting crystal is located on the flag-shaped cathode and is connected to the anode by the thinnest wire. There are models with two and three crystals of different colors in one package with the number of pins from two to four. In addition, a microchip can be built inside the case, which controls the sequence of the crystals glowing or sets the purity of its blinking.  LEDs in a DIP package are low-current ones, used in backlighting, display systems and garlands.

LEDs in a DIP package are low-current ones, used in backlighting, display systems and garlands.

In an attempt to increase the luminous flux, there was an analogue with an improved device in a DIP package with four pins, known as "piranha". However, the increased light output was offset by the size of the LED and strong heating of the crystal, which limited the scope of the "piranha". And with the advent of SMD technology, their production has practically ceased.

SMD

Surface-mounted semiconductors are fundamentally different from their predecessors. Their appearance expanded the possibilities of designing lighting systems, made it possible to reduce the dimensions of the luminaire and fully automate the installation. Today the SMD LED is the most demanded component used to build light sources of any format.

Surface-mounted semiconductors are fundamentally different from their predecessors. Their appearance expanded the possibilities of designing lighting systems, made it possible to reduce the dimensions of the luminaire and fully automate the installation. Today the SMD LED is the most demanded component used to build light sources of any format.

The base of the case, on which the crystal is attached, is a good heat conductor, which significantly improves heat dissipation from the light-emitting crystal. In the device of white LEDs between the semiconductor and the lens, there is a layer of phosphor to set the desired color temperature and neutralize ultraviolet radiation. In SMD components with a wide angle of radiation, there is no lens, and the LED itself has the shape of a parallelepiped.

COB

Chip-On-Board is one of the newest practical advances, which will take the lead in the production of white LEDs in artificial lighting in the near future. Distinctive feature The LED device is as follows: tens of crystals without a case and a substrate are attached to an aluminum base (substrate) through a dielectric glue, and then the resulting matrix is \u200b\u200bcovered with a common phosphor layer. The result is a light source with a uniform luminous flux distribution, eliminating shadows.

Chip-On-Board is one of the newest practical advances, which will take the lead in the production of white LEDs in artificial lighting in the near future. Distinctive feature The LED device is as follows: tens of crystals without a case and a substrate are attached to an aluminum base (substrate) through a dielectric glue, and then the resulting matrix is \u200b\u200bcovered with a common phosphor layer. The result is a light source with a uniform luminous flux distribution, eliminating shadows.

A variation of COB is Chip-On-Glass (COG), which involves placing many small crystals on a glass surface. In particular, it is widely known in which the emitting element is a glass rod with LEDs coated with a phosphor.

How the LED works

Despite the considered technological features, the operation of all LEDs is based on the general principle of operation of the emitting element. Conversion of electric current into luminous flux occurs in a crystal, which consists of semiconductors with different types conductivity. Material with n-conductivity is obtained by doping it with electrons, and material with p-conductivity with holes. Thus, in adjacent layers are created additional media charge of the opposite direction.  At the moment of applying the forward voltage, the movement of electrons and holes begins to the pn junction. The charged particles overcome the barrier and begin to recombine, resulting in an electric current flowing. The process of recombination of a hole and an electron in the p-n-junction zone is accompanied by the release of energy in the form of a photon.

At the moment of applying the forward voltage, the movement of electrons and holes begins to the pn junction. The charged particles overcome the barrier and begin to recombine, resulting in an electric current flowing. The process of recombination of a hole and an electron in the p-n-junction zone is accompanied by the release of energy in the form of a photon.

In general, this physical phenomenon applies to all semiconductor diodes. But in most cases, the photon's wavelength is outside the visible radiation spectrum. To make an elementary particle move in the range of 400-700 nm, scientists had to conduct a lot of experiments with the selection of suitable chemical elements. As a result, new compounds appeared: gallium arsenide, gallium phosphide and their more complex forms, each of which is characterized by its own wavelength, and hence the color of the radiation.

In addition to the useful light emitted by the LED, some heat is released at the pn junction, which reduces the efficiency of the semiconductor device. Therefore, in the design of high-power LEDs, the possibility of implementing effective heat dissipation should be considered.

Read the same

Everywhere there is a replacement of conventional lamps with LEDs. It is by far the best lighting solution for cars and homes, more durable and easier to replace. So, what is the principle of the LED and how to choose it correctly?

LED and how it works

An LED is a special electrical device that converts current into some kind of glow. Today, LEDs are more commonly known as LED, which stands for light emitting diode.

The device is a semiconductor device and consists of a crystal chip, a housing, pins and an optical device. The light comes from the crystal, and its color may vary depending on the material used. The brightness of the LED, as well as its color, can also be different. So, for example, for a greater light effect, several crystals are often inserted into one lamp, producing a single-color light, which together forms a bright glow.

The brightness of the device directly depends on the strength of the electric current supplied to it. In turn, an excessively powerful flow of electricity causes rapid overheating of the inner crystal and disables it. In view of this, the design of the LED is somewhat costly in terms of the cost of materials, which somewhat negatively affects the choice of such lamps.

By brightness, LEDs are usually divided into categories:

- ultra-bright, their minimum power is 1 W;

- high brightness LEDs - up to 20 mW;

- standard lamps.

Today, a LED block is widely used, which is built into a lamp. Thanks to it, the choice of the optimal glow mode is also possible.

The advantage of LEDs over other types of lighting

LED is the best choice of lighting type today, which has several advantages:

- Durability.

- Adjustable lamp color and brightness.

- Color saturation, the ability to match the red, blue, green LED or make the color change.

- Possibility of electronic control.

- Environmentally friendly materials that do not contain heavy substances that are harmful to the environment and hazardous if not properly disposed of.

- Low power consumption, several times more light is generated per watt.

- The light is pure and as close to natural as possible.

- They do not overheat thanks to a competent light outlet.

- Reliability and durability.

Why have LEDs become popular in the auto industry? This type of lighting is ideal for cars, gradually replacing halogen and xenon bulbs. Its positive qualities:

- the ability to direct the lighting behind the steering wheel - the creation of adaptive headlights;

- looks aesthetically better than other types of headlights;

- increased safety through improved visibility on the road;

- vibration resistance;

- often LEDs are installed in a housing where moisture does not penetrate;

- reaching the working condition is faster, for this reason the brake lights work better.

Of course, these advantages are inherent only in really high-quality products, so it is not worth saving on them, especially since the period of their operation has been significantly increased compared to Chinese products. Additionally, the service life of LED lamps, when compared with conventional ones, is also much longer.

Classification of LEDs

There are 2 main types of LEDs - for backlighting (indicator) and for lighting. Their strength and durability depend on the supply of electric current, therefore, the second type of LEDs serves a shorter period, since the crystal wears out faster. However, these lighting devices are very durable and last several thousand hours.

An illuminating LED is a device that provides reliable and powerful light. It is widely used in design, creating the desired level of illumination.

According to the type of case, it is customary to distinguish an LED in the form of "Star", "Piranha" and SMD. Among them, the most popular are "Piranhas", as their luminous flux seems to be of higher quality. Their design feature is the shape of a rectangle with leads along the edges, with the help of them, rigid adhesion to the surface is ensured. In addition, the substrate of the device has excellent heat dissipation properties. These devices are widely used in automobiles and advertising. They are of various sizes and colors: red, white, green, blue LED.

Indicator LEDs have a simpler design, their light is not as strong and are used to illuminate displays and dashboards. Round, oval and rectangular indicator LEDs are distinguished in shape.

Lenses also differ from each other, they can be built into lighting, and in some are designed to diffuse light (the vast majority of these devices), others - for focusing, thanks to a directed beam of light produced. Moreover, in the second group, lenses are distinguished: flat, conical and round.

By the color of the lens, LEDs are:

- colorless transparent;

- colored transparent;

- painted matt.

In addition, the color scheme of the device is now very diverse. There is yellow, red, blue, green LED, etc. These colors are skillfully combined to create an even wider spectrum. The most difficult, oddly enough, to get pure white.

A white LED is obtained in three ways:

- using red, blue and green in the right proportions at the same time gives the impression of white;

- the use of a blue diode with an admixture of yellow;

- the third method requires the use of fluorescent materials, which transforms ultraviolet light, acting like a fluorescent lamp.

White LED is the most common, although somewhat difficult to obtain. It can be cold and warm. On a light bulb, this parameter is usually indicated in kelvin, the lower the indicator, the yellower and warmer the color will be. Manufacturers recommend opting for an average parameter, although cold, bluish light can also quickly get used to.

Choosing a lamp for home

The choice of a lamp for the home includes several stages, where it is necessary to determine the type of network, the diameter of the base and the appearance of the lighting device itself.

The 220 volt LED is produced in the most common types of caps - E27 and E14. The numbers indicate the thread diameter in millimeters. The first type of lamp is often found in the form of a ball, the second - a ball or corn.

What are their main advantages? Firstly, it is the ability to block and adjust the brightness of the glow yourself. Secondly, it is the choice of color lighting and the ability to remotely control it. Thirdly, the durability of operation and increased reliability.

When choosing a shape, you need to pay attention to the fact that corn lamps, although they have quite good characteristics, are still unsafe. Their contacts go out, and manufacturers have recently refused to release devices of this form.

For lighting non-residential premises or bathrooms, less powerful lamps are used, so if you do not need to use a 220 volt LED, you can do with small flat devices with a G53 and GX53 base. These are round lamps that use multiple diodes.

When purchasing a lamp, pay attention to the following characteristics:

- the number of diodes - the brightness of the lamp depends on how many LEDs are in the lamp, especially with a long period of use, when they begin to fade and burn out;

- mode working temperature - it should be borne in mind that when choosing a lamp for the street, it must be effective even in possible frosts, this is usually indicated in the device's passport;

- the possibility of pulsations - blinking is found in cheap lamps, usually when buying an expensive one, it is minimized;

- operating conditions sometimes require increased protection of the device, for example, resistance to moisture, you need to ask the seller about this parameter;

- when choosing a manufacturer, you need to pay attention to the diameter of the base, since not all foreign developers produce a 220V LED;

- the required luminous flux, which is measured in Lumens, is lighting or indicator lamps.

Manufacturer's choice

There are many manufacturers on the market who demonstrate different levels of quality. Accordingly, their supplier pricing also differs significantly.

The main disadvantage of LEDs is their cost. Therefore, if you are already paying a lot of money for a product, it is necessary that it be really high quality. Therefore, it is worthwhile to take a responsible approach to the choice of a manufacturer and supplier.

Manufacturers can be conditionally divided into 5 groups.

- Chinese cheap brands unknown to anyone.

- Well-known Chinese and Asian manufacturers. The most popular are Selecta, Camelion, LG. They use modern equipment, and the quality of the products produced by these companies is quite high, so a fairly large segment of the domestic market is occupied by goods from Asia. Separately, it is worth noting LG LEDs, which since 2016 have significantly reduced the price of their goods due to the use of new technologies in production. Moreover, the quality remains the same. There is no doubt about it. The company specializes in medium-power lamps and shows itself quite well relative to analogues.

- Domestic manufacturers who make a high quality product, but their technology is quite expensive, so the price of lamps is corresponding. Unfortunately, on the territory of Russia it was late to learn about the wide possibilities of LEDs and there are not so many domestic manufacturers so far. These are, for example, Optoman and Gauss. These companies have their own the lineup products and are available throughout the country.

- European manufacturers are represented mainly by German firms Philips, Osram, Bioledex, which have vast experience in the production of lamps. Perhaps Philips remains the leader in this market segment, although it is relatively expensive.

- Sino-Russian projects such as Ecola, Newera are also brands of good quality and price, which are much younger than competing firms.

Thus, among such an abundance of manufacturers, it is sometimes quite difficult to choose a worthy brand, therefore it is especially important and necessary to pay attention mainly to the characteristics of the product and its operating conditions.

Approximate algorithm of actions when installing the LED

If you have even the slightest knowledge of electrics and had experience installing any lamps, you can try to install the LED yourself. First you need to make sure that the lamps are working. The sequence of actions should be as follows:

- study of technical characteristics and counting how many volts one LED consumes;

- drawing up a connection diagram taking into account voltage;

- calculation of the power consumption of the electrical circuit;

- then you need to choose a power supply that would fit in power, it can also be a driver;

- the LED legs indicate the polarity to which you need to solder the wires;

- connecting the power supply;

- installation of diodes and their fastening;

- if everything is in order, it is necessary to measure such characteristics as the amount of energy consumed, heating, electric current;

- correction of electric current;

- warming up for half an hour - so that nothing happens during the initial installation and in order to prevent overheating, it is better to buy LEDs on a star-shaped substrate.

During operation, especially if these are Chinese products, sometimes it is necessary to replace the LEDs. Instead of contacting specialists, the replacement can be done independently if you have the necessary tools. Having unrolled the lamp, using digital multimeter ringing diodes. These, in turn, are dimly highlighted, and some of them may not work. Unnecessary diodes are soldered off and replaced with new ones. Of course, this happens when spare LEDs are available, for this you can take an old lamp.

Today, a popular addition is the Arduino program. The LED, connecting to it, can be made to blink. The Arduino board has many possibilities, I / O, and you can connect almost any device to it. This program is capable of receiving signals from various devices, which makes you affect them. It is an easy and convenient programming environment that is easy to handle even for an ordinary user.

Choice of LEDs for the car

Car owners are increasingly switching to a new type of lighting in their car. It's really good decision not only in terms of the operating mode, but also relatively appearance car. The car will significantly change, attracting the glances of passing drivers. All lamps used in the car can be safely replaced with lighting.

How to choose the dimensions and light for the front brake lights?

Most of the automotive industry uses lamps without a base, installed in the gap between the headlights. The advantage of LEDs is their resistance to any temperature, since they are located close to the main lighting lamp, overheating of the crystal is possible and its premature failure. In view of this, when choosing lighting, you need to pay attention to the additional protection of LEDs - the presence of an electric current stabilizer.

When choosing lamps, you need to pay attention to their series, for example, the SF series, although it does not have a stabilizer, is quite suitable for a car, since it has a large number of diodes and works in a wide range, perfectly illuminating the space.

You also need to pay attention to the dimensions of the lamp, so the above example SF is enough big device... You need to think carefully about everything before buying lighting.

Also popular is the series for dimensions - SMD, which has excellent characteristics, but also costs a lot of money.

Rear car lighting

It is customary to equip rear brake lights with base two-pin LEDs. The most popular series: MSD, 14HP and 3x1W. They have a slightly different operating mode, differ in the number of diodes. But they all have fairly high rates. These LEDs are bright, provide rich light and long life.

The most affordable are SF series lamps.

Interior LEDs

Before choosing lamps for the interior, you must decide on the type of lighting and the size of the shade.

In the salon, you need to pick up a festoon-type lamp - these are oblong devices, 31-41 mm in size. There are 3 types of interior LEDs.

- Installed in the plafond connector instead of the old conventional light bulb. In size, such LEDs are almost identical to conventional lighting devices, they are used when it is impossible to use another lamp due to the small size of the plafond.

- Larger LEDs than a standard bulb. Before installing the required one, make sure whether such a device fits under the ceiling. Due to the larger size, the number of diodes in the lamp also increases. Thus, the lighting becomes much brighter than usual.

- Matrix containing a large number of diodes. If the plafond is large enough to accommodate a rectangular matrix, then this type of lighting will be the brightest and most saturated.

The interior lighting uses SF or SMD lamps.

In addition, replacement of fog lamps with LED lamps is widely used in cars. Particular attention should be paid to motorists who want to stand out from others, to the backlight led strip and on "angel eyes".

Summarizing

LED is a great alternative to old light bulbs, which helps to solve the problem of insufficient lighting in the room. Even at a higher cost than a conventional lamp, this is an excellent investment, as the LED can last for more than one year and give bright light to your home and car.