Components:

1. Prism

2. Light plate

3. Calibration screw;

4. Mirror pipe

5. Adjust focus

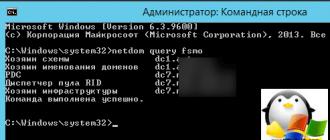

Operating procedure:

1. Open the light plate. Wipe the surface of the prism with a soft cotton cloth. Apply 2-3 drops of test solution to the prism. Close the prism with a light plate and press it lightly, then you can read the readings from the scale at the border of the light and dark areas. The readings correspond to the value related to the solution.

2. Point the front edge of the refractometer at a bright light source and adjust the focus so that the measurement scale in the eyepiece is clearly visible.

Calibration.

3. Open the light plate and put 2-3 drops of distilled water on the main prism. Close the light plate and lightly press it so that the water is distributed over the entire surface of the prism without forming bubbles or dry patches. Let the sample rest on the prism for about 30 seconds. Now adjust the calibration screw so that the border of the dark and light areas falls exactly on the zero line.

4. The temperature compensation refractometer should be set up at an ambient temperature of 20°C.

5. If the operating temperature in the room or measurement site (but not the sample) has changed by more than 3°C, it is recommended to recalibrate to improve measurement accuracy.

6. The working procedure is carried out after calibration in the same sequence as the calibration itself.

7. After measurement, wipe off all solution from the surface of the prism and light plate with a damp cotton cloth. After drying, the plate must be pressed again well.

Service Warnings.

8. Zero setting. Liquid and sample must be at the same temperature. If the temperature differs greatly, the zero point must be reset every 30 minutes.

9. After use, never wash the device with water to prevent water from getting inside the device.

10. Since the device is a precision optical instrument, it should be handled with care and taken good care of. Never touch or scratch optical surfaces. Store the device in a dry, clean place, away from sources of corrosion, and also protect the surface from fog and mold. When transporting, avoid sudden shocks.

11. If you use the tool in accordance with the specified methods, then it is guaranteed that it will never become unusable. The optical properties of the device do not change over time.

Temperature correction

12. Automatic temperature compensation range (ATC-80): 10°C to 30°C

13. The base temperature of the device is 20°C. During operation, temperature compensation should be carried out according to the table. Models marked ATC are equipped with an automatic temperature compensation function. Therefore, for them, temperature correction according to the table is not required.

What is a refractometer?

A refractometer is an optical instrument that measures the refractive index of light in a medium. Refractometry, performed using refractometers, is one of the most common methods for identifying chemical compounds, quantitative and structural analysis, and determining the physicochemical parameters of substances.

The operation of a refractometer is based on measuring the refractive indices of light in various media. If the density of substances increases, its refractive index increases proportionally (for example, when sugar is dissolved in water). The refractometer reads the relative "weight" of the sample compared to distilled water.

Calibration and use of the refractometer

Wait approximately 30 seconds before you proceed to the next step. This will allow the sample to adapt to the ambient temperature.

Point the refractometer in the direction of natural daylight and look through the eyepiece. You will see a circular area (field) centered at the bottom. (Figure 1 shows the scale without calibration fluid or any other fluid.) |

|

Tighten the calibration screw until the boundary between the upper blue area and the lower white area meet exactly at zero. |

|

Figure 3 illustrates what you see at this stage.

|

Picture 1 This drawing illustrates what you can see in the eyepiece without any pattern. Note that the entire scale is colored blue. When viewing, make sure you use natural daylight. You should not take readings in the presence of fluorescent light. |

|

Figure 2 This is what you see after the refractometer has been calibrated. Note that when properly calibrated, the blue and white scale should be exactly at zero when using distilled water as a sample. |

|

Figure 3 This example shows the scale when measuring grape juice. You can see that the gauge reads 23% Brix, the perfect time to make wine! After finishing the measurement, make sure you clean and dry the refractometer. |

Refractometer Maintenance

Accurate measurement depends on careful and correct calibration. A reminder that differences between the ambient temperature and the sample temperature reduce the accuracy of the reading. Be sure to wait approximately 30 seconds before taking readings.

Do not immerse the instrument in water or allow water to enter the interior.

Do not measure harsh or corrosive chemicals with this instrument because they may damage the prism coating.

Clean the instrument between each measurement using a soft cloth.

Refractometer is an optical instrument. It requires careful handling and storage. With careful use and proper storage, this tool will provide years of reliable performance.

The calibration air temperature should be 20°C. However, many modern models come with ATC (Automatic Temperature Compensation) so you don't have to worry about the calibration air temperature or sample temperature.

Sources: www.grapestompers.com, www.patech.ru

Refractometer for honey portable RHB-90 ATC.

Dimensions (mm): 220×80×55.

Weight (g): gross 345, instrument 220±2%.

Materials and elements used in the manufacture of goods:

the kit includes

- Refractometr RHB-90 ATC /Automatic Temperature Compensation System/ (does not require power supply);

- measuring pipette;

- screwdriver;

- plastic case.

Description: The RHB series of portable refractometers is designed to work with sugar-containing liquids (fruit juices, soft drinks, honey, wine), and allows you to see and control the concentration of sugar in food products, determine their moisture content. Refractometers provide important information for product quality control.

The portable refractometer RHB-90ATC allows you to quickly and accurately measure the moisture content of honey on the WATER% scale. According to GOST, the moisture content of honey should not exceed 19%.

The device is compact and does not require power supply. Has the built-in temperature corrector of automatic telephone exchange. With the help of which a high accuracy of measuring the moisture content of honey in the range of 12 ... 27% is achieved. The advantage of ATS is that the bimetallic plate inside the case and connected to the optical system of the refractometer is compressed or stretched depending on the temperature difference, thereby smoothly moving the optical system with temperature changes. The magnitude of the shifts is calculated so that the effect of temperature on the refractive index of the substance is completely compensated. The device with automatic telephone exchange, after appropriate calibration, allows to obtain accurate measurements at ambient temperature within the allowable range of +10...30°C.

Attention! Refractometers are supplied already calibrated and calibration is not initially required for use.

Calibration:

Calibration of the RHB-90ATC portable refractometer should only be carried out at an ambient temperature of 20°C.

Step 1. Open the prism cover and pipette 2-3 drops of calibration fluid (diopter oil) onto the prism. Close the prism cover so that the liquid spreads over the entire surface of the prism without air bubbles or gaps. Wait approximately 30 seconds for the refractometer to auto-tune.

Step 2 Point the prism at the light source and observe a circle with the appropriate scales through the eyepiece of the refractometer (you may need to focus the eyepiece to achieve a clear image). The top of the circle should be blue and the bottom white.

Step 3. Use the adjusting screw to adjust the blue and white field border at the level of 78.4%, corresponding to the middle of the refractometer scale, as shown in the figure.

Measurements:

Do step 1 (see above) using a sample of honey or liquid to be evaluated in place of the calibration solution.

Next, follow step 2. The border of the blue and white fields will indicate the values on the corresponding 3 scales: the percentage of water - WATER% (used mainly in Europe), the percentage by weight of the concentration of sucrose - sugar level Brix% (American standard), a measure of density Baume fluids - Be° (Asian standard).

At ambient temperatures other than 20°C, the measurement readings of the RHB-90 refractometer without the built-in temperature corrector ATC must be corrected with correction values.

General remarks and maintenance:

The accuracy of the measurement depends on careful calibration and the same temperature of the prism of the refractometer and the measured sample. Follow the instructions carefully.

Avoid using the appliance in humid and damp environments and do not submerge it in water. If water enters the unit, the image may become blurry and a qualified technician may be required.

Do not expose the refractometer to abrasive or harsh chemicals. This may damage the prism coating.

Clean the instrument after each measurement with a soft and damp cloth. Failure to clean regularly will result in erroneous results and damage to the prism coating.

This device is an optical instrument and should be handled and stored with care. Failure to do so may result in damage to the optical components and structure of the device.

Compliance with the above requirements will ensure many years of reliable operation of the refractometer.

Characteristics of RHB series models:

|

Range |

Scale step |

Accuracy |

Note |

|

|

Baume +/-0,5Be° |

||||

|

Baume +/-0,5Be° |

||||

|

Baume +/-0,5Be° |

Automatic temperature compensation - yes |

Brix scale - displays a measure of the mass ratio of sucrose dissolved in water to liquid. Solution in Brix 80% means 80 grams of sugar/sucrose in 100 grams of liquid.

The Baume scale is a scale with conventional Baume degrees, which is a measure of the density of a liquid. Zero degrees of this scale corresponds to the density of pure (distilled) water at 15°C, and the value of 15Be° corresponds to the density of a 15% sodium chloride solution.

WATER scale - displays the percentage of water in the test liquid.

According to clause 8.3. The online store is not responsible for technical ideas, design features, innovative ideas, colors, weight, dimensions, etc. goods manufacturers. The product must perform the functions declared on the site, while why the manufacturer of the product did one way or another in terms of design and manufacture, the online store does not answer.

The ATC40 handheld optical refractometer is a professional instrument for measuring the percentage of alcohol in grape must and sugar in wine. The principle of operation of the device is based on determining the refractive index of a sugar-containing liquid, which is proportional to the concentration of sugar. This determines the maximum accuracy of the measurements.

Specifications

- Measuring range - 0~40% sugar (Brix), 0~25% alcohol

- Measurement step - 0.2% sugar (Brix), 0.2% alcohol

- Accuracy - ± 0.2% Brix, ± 0.2% alcohol

- Automatic Temperature Compensation Yes (Range: 0°C~30°C)

Instruction

- Point the front edge of the refractometer at a bright light source and adjust the peephole so that the crosshairs of the reticle are clearly visible.

- Perform calibration:

- Open the light plate and put 2-3 drops of distilled water on the main prism.

- Close the light plate and press it lightly so that the water is distributed over the entire surface of the prism without forming bubbles or dry patches.

- Leave the sample on the prism for approximately 30 seconds.

- Adjust the calibration screw so that the border of the dark and light areas falls exactly on the zero line.

- Take measurements:

- Open the light plate.

- Wipe the surface of the prism with a soft cotton cloth.

- Drop 2-3 drops of the test solution onto the main prism.

- Close the light plate and press lightly.

- Take readings from the scale at the border of light and dark areas. The readings correspond to the value related to the solution.

- After measurement, wipe off all solution from the surface of the prism and light plate with a damp cotton cloth. After drying, the plate must be pressed again well.

The device is designed to work with alcohol and syrups related to winemaking. It measures the sugar content of the grapes, which helps the producer choose the optimal time for the production of grape wine.

|

Range |

Value of division |

Error |

|

|

0-40% Brix |

0.20% Brix |

±0.2% Brix |

|

|

RHW-25/Baume/ATC |

|||

|

±1% wt. |

Notes:

1) If this is a new version of the model, the letter N is added to its name, for example: RHWN-25ATC, etc.

2) Automatic temperature compensation (ATC) range: 10°C to 30°C

3) Models RHW-25/ATC and RHW-25/Baume/ATC are commonly used to determine the alcohol content of grape wine made from natural grape juice.

Components:

Components with a new design

1----Light plate; 2----Calibration screw; 3----Focus adjustment; 4 ---- Peephole; 5----Calibration screw retainer

Operating procedure:

1) Point the front edge of the refractometer at a bright light source and adjust the eye so that the crosshairs of the sight are clearly visible.

2) Calibration.

Open the light plate and put 2-3 drops of distilled water on the main prism. Close the light plate and lightly press it so that the water is distributed over the entire surface of the prism without forming bubbles or dry patches. Let the sample rest on the prism for about 30 seconds. Now adjust the calibration screw so that the border of the dark and light areas falls exactly on the zero line.

The temperature compensated refractometer should be set up at an ambient temperature of 20°C.

If the operating temperature in the room or measurement site (but not the sample) has changed by more than 3 °C, it is recommended to recalibrate to improve measurement accuracy.

3) The operating procedure is followed after calibration in the same sequence as calibration. Open the light plate. Wipe the surface of the prism with a soft cotton cloth. Drop 2-3 drops of test solution onto the main prism. Close the light plate and press it lightly, then you can read the reading from the scale at the border of light and dark areas. The readings correspond to the value related to the solution.

4) After measurement, wipe off all solution from the surface of the prism and light plate with a damp cotton cloth. After drying, the plate must be pressed again well.

Service Warnings.

1) Zero setting. Liquid and sample must be at the same temperature. If the temperature differs greatly, the zero point must be reset every 30 minutes.

2) After use, never wash the device with water to prevent water from getting inside the device.

3) Since the device is a precision optical instrument, it should be handled with care and taken good care of. Never touch or scratch optical surfaces. Store the device in a dry, clean place, away from sources of corrosion, and also protect the surface from fog and mold. When transporting, avoid sudden shocks.

4) If you use the tool in accordance with the specified methods, then it is guaranteed that it will never become unusable. The optical properties of the device do not change over time.

Temperature correction

The base temperature of the device is 20°C. During operation, temperature compensation should be carried out according to the table. Models marked ATC are equipped with an automatic temperature compensation function. Therefore, for them, temperature correction according to the table is not required.