Every owner of a Canon inkjet printer (regardless of its model) sooner or later encounters the B200 error, which occurs a little more often with devices that use not cartridges, but a print head. Ways to solve this error will be described below, so that you can solve the breakdown yourself, without calling the master at home. But we ask you to be careful and careful with your technique. When this error occurs, the manufacturer Canon recommends turning off the device and contacting the nearest service center in your city. As you can imagine, it is profitable for them, but not for us. And so let's deal with this problem together.

We urge you to read the article to the end. This error is not easy and requires testing. Therefore, take a piece of paper with a pen and write down our recommendations. Perhaps you forget to do some method, and then you already have to go to the service center. At the bottom of this article, there is a selection of videos that will allow you to see clearly how to solve this problem.

Attention! If your printer is under warranty, then don't do anything, close this article, or just read it if you're interested. If you start disassembling the device, then your warranty will be void and you will have to pay for repairs from your entire wallet. So it's best to take your device to the store where you bought the printer and let them decide what to do with your device. Are you out of warranty? Then let's get down to reading this article.

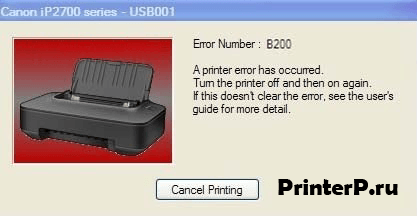

When this error occurs, the following window appears in front of the user:

Also this error can be in English:

Of course, you must understand that the language does not affect the solution of the problem in any way. Now let's get down to solving this issue.

This error can also be seen on the printer displays:

When this error appears, the printer behaves abnormally - the indicators on the device panel blink alternately yellow and green. Canon thus makes it clear to the user that problems have appeared on your device - error B200. This error is also called "VH monitor error" - a problem with the power supply of the print head or it is possible that some cartridge is not working for you. In other words, this is a kind of signal that there is a problem in the print head or in one of the cartridges. In addition, when this error appears, it can be a signal of a breakdown of the power supply, but the latter problem does not arise often, and we can say for sure that if this is the problem, then you are lucky.

Canon devices may notice that you installed a non-original cartridge and therefore you get a B 200 error. If you recently bought a cartridge or if you knew that it was Chinese, then it makes sense to try to insert the original cartridge and see how the device reacts.

It should also not be ruled out that even if the cartridge is guilty and you replaced it, then the head may fail, which, while using a non-original cartridge, overheated and, as a result, burned out. After replacing the cartridge, you may be lucky and the error will go away. It remains to check it out.

In the event that you have empty cartridges, be sure to refuel them!

Another very important point is the cartridges. If your device has 2 cartridges, remove them from the printer and insert them into the device one by one. If you get an error when connecting one of the cartridges, then one of them is faulty.

A quick way to solve the problem

- After the B200 error appears, turn off the MFP;

- Open the cover, move the carriage to the left as far as possible;

- Press the on button 5 times. (without waiting for full on / off);

- Close the cover after the last press.

Flushing

This method will not work with all Canon printers and MFPs. After reviewing this instruction, you will understand whether this method can be performed on your device. Now watch the video for ordinary users who do not have special tools:

Sorry, these videos are in English. But in any case, the video shows what needs to be done.

Initial diagnostics

First, you need to diagnose your printer in order to already know for sure what is wrong with it. Power supply problems are often identified by visual inspection. The capacitors on the failed power supply unit will be swollen. Just in case (if visually everything is normal with the unit), you can also measure its voltage at the connector of the control board.

At the time of starting the printer (when you press the power button), the voltage indicator should be in the interval of 0.5 s with data of 24-32 V, which is quite normal for this device. Another way to test the power supply is to connect it to a guaranteed working Canon printer. But here you have to be careful. Under no circumstances connect a working unit to a printer with a B200 breakdown, because if a print head or control board burns out in it, the new power supply will suffer the same fate. In order not to break 2 devices at once, we ask you not to do this.

If, when checking the unit, a breakdown did not appear, then you need to remove the print head from the printer and look at the monitor. Does the B200 error still occur? This means that there is a malfunction in the control board and still not very good news - perhaps you also have a burned out controller with a print head. The saddest thing is that if you buy these devices, the amount will be equal to the cost of a new printer or Canon MFP, which means that a trip to the store for a printer is inevitable.

It's another matter if after you took out the print head, the error disappeared, and a new message on the monitor informs you that there is no head in the printer, which must be installed for its further operation. This means that the control board is most likely (not 100%, but still) working properly and the problem is solely with the printhead.

If such an error appears in the MFP, can at least the scanner be “saved”?

In Canon devices, with a B200 error, you can turn the following - it is necessary to seal all the PG contacts (see the figure below) with electrical tape (but do not use transparent tape for this purpose), after which the controller will not receive signals about the breakage of sensors and it will begin to read the print head serviceable. This will save you from error B200 and allow you to use the scanner (since you do not need a print head for scanning).

The trick here is that if at least one sensor fails, the Canon controller will perceive the entire system as faulty. When gluing the contacts with insulating tape, we get the opportunity to use at least a scanner. In the picture below, we showed how many contacts need to be sealed with electrical tape and also wrote how many contacts are in the shaded area. It is necessary to glue it as in the picture:

Individual cartridges can still print

When your contacts have been sealed, you can carefully remove pieces of electrical tape, freeing one of the contacts, and install the head into the device each time. If an error occurs, return the tape to the newly unsticked contact and continue the same manipulations with other contacts. So we will eventually come to a situation that only non-working contacts will be sealed with us, while serviceable cartridges will print.

After doing the manipulations described below, the device will stop showing the B200 error after a couple of days, and maybe after 15 minutes. It should be noted that when using this option, the device can work from 2 weeks to 1 year.

Below are the pictures showing which contacts you can try to glue.

1.If you seal these contacts with electrical tape, you can print with a black cartridge:

2. If the device works with this option, then you will be able to print only with color cartridges:

2. If the device works with this option, then you will be able to print only with color cartridges:

3.In this case, you can print in black and color:

3.In this case, you can print in black and color:

4.And the last option is black and colored:

Note: There is a video below that shows how this is done.

Can error B200 be avoided?

There is an opinion that the breakdown of the controller, generator or power supply unit occurs due to surges in the power grid, therefore it is highly recommended to use an UPS (uninterruptible power supply), which has a voltage regulation function. In addition, the following can often lead to an error: refilling cartridges with ink of dubious quality, installing a PG that has not yet dried after flushing and printing with empty cartridges.

It should be noted that it is difficult to keep track of the ink level in branded cartridges, because they are made of opaque plastic (for this reason, do not disable the ink level control function). You can of course supply a continuous ink supply system, but not all users agree to this procedure.

Summing up

If the solutions that are described here did not help you, then you should think about finding a service center that can help you. Even if they do not help, they will tell you what the reason is, and you will already start from this figure - make a device or buy a new one.

Finally, we will say that if you have an error B200, then this is very, very bad, since most often the repair will be extremely costly and will not always be effective. Before you go to the store, don't panic and try the tips and tricks described above. It is quite possible that it is with you that the problem will be solved with "little blood". Good luck to you!

If you have such an error, then we ask you to write a comment at the bottom of the article with the following information: printer model, how long have you been using the printer and after which the error appeared.

Difficulty level: Easy

Step 1

Power Supply. An error may occur due to a faulty power supply. If so, then consider yourself very lucky. To check, you need to measure the voltage at the output of the printer power supply with a tester. It should be 24V and 32V. It will also be useful to disassemble the power supply unit and inspect the unit board for the presence of swollen capacitors, burnt tracks, etc. If there is no voltage or it is lower / higher than the norm, then the power supply unit requires replacement. But if the voltages are in order, then the power supply has nothing to do with it.

Step 2

Printhead. Remove the cartridges from the printer, then remove the printhead. Turn on the printer, if the error has disappeared, then the problem is in the steam generator and it needs to be replaced (expensive piece, price from $ 50). Replacing a gas generator is sometimes more expensive than a new printer.

Step 3

Formatter. The formatter is the control board of the printer. You can check it like this: remove the cartridges and PG and turn on the printer. If there is no movement or sound, the error will remain - it means that 98% of the formatter is defective. It is very difficult to find such boards on sale, and if you do find them, the price will be inadequate. There are two options left: a printer in the trash heap, or a search for a used "donor" of the same model with a 100% working control board. Of course, if the printer is under warranty, then you shouldn't have any problems. But, as a rule, such a malfunction occurs after several years of use. Source site

- Refill the printer with quality ink to avoid such problems.

When a particular technique breaks down, many wondered which service center to choose. Now the list of firms that are engaged in repairs is quite large and continues to grow. Therefore, the choice is quite large.

In this article, I will try to give some advice on what you need (or not need) to pay attention to when handing over the equipment for repair. After all, the amount of money, time and nerves you spend directly depends on the right choice.

1. Do not pay attention to the respectability of the premises for receiving equipment, the number of staff and other trifles. You have to pay rent for the extra square meters, and the receptionist girls need to be paid a salary. So the prices for services need to be raised a little. Of course, there are exceptions, but they are few. I do not urge you to put your favorite laptop or printer in the basement to an incomprehensible person, who is both a foreman, an inspector and a director of the company. But a small company, in which one, but an intelligent person, works at acceptance, does not need to be swept aside right away.

2. Specify whether you pay for diagnostics, if the technician was unable to repair the device, or if you refused to repair it. The requirement to pay for diagnostics in case of failure is quite normal, the foreman spent his time working with your equipment. For example, I do not charge for diagnostics only if I cannot repair the device or the repair costs more than half the price of a new one.

3. Specify whether you pay for the spare parts ordered by the master if the item could not be repaired. If so, run from this service. You do not have to pay for the mistakes of the master, just because he did not correctly identify the breakdown and ordered the wrong spare part.

4. It would not be superfluous to ask about the maximum repair time. Also stipulate that you would be contacted and announced the full cost before the start of the repair. Otherwise, you risk getting a bill, for example, 80% of the price of a new device. And, since the repair is over, it will be very difficult to prove anything.

5. Read the repair receipt carefully. If you have agreed on some conditions, and the receipt indicates others, your verbal agreements have no effect. Also pay attention to the description of the defect, appearance and equipment of the device. If something is indicated incorrectly, this will enable the service center to return the device not in the configuration in which you handed it over, with mechanical damage or with another defect. For example, you gave a laptop with a "No sound" defect, and the receipt says "Doesn't work". The service center can give you your laptop, which no longer turns on.

6. It will not be superfluous to ask for a list of spare parts and their cost before starting the repair and compare with prices in the net. In this case, a margin of up to 40 percent is allowed. Many parts are supplied without warranty or may be damaged during installation. You also need to consider the cost of delivery. Therefore, a certain margin at the cost of the SC should be left. But if the prices differ by 2-3 times, it is worth considering.

You can also look at reviews on the Internet about a specific service or find out what service centers are in your region. For example, type "Printer repair in Minsk" into the search. Just do not forget, the negative will be necessary. It is necessary to assess not the presence of a negative, but its quantity.

In any case - make the right choice and good luck to you!

Greetings, dear visitors. Quite often I am asked how to extend the life of a Canon cartridge or print head.

First of all, I’m talking about inkjet cartridges for Canon printers. Such as CL-511, PG-510, CL-446, PG-445, CL-441, PG-440 and others. That is, we are talking about conventional inkjet printers and MFPs that have two cartridges. For example MP280, MP230, MG2440, E404, MG3540 and others. But this also applies to Canon printers using a print head and ink tanks.

Let's see how these printers print. I warn you right away, I will explain the principle of printing in a very simplified way.

The cartridge contains an absorber - a sponge that contains ink. From this sponge, they are fed into the nozzles (nozzles). Nozzles are very small diameter tubes. Each tube contains one or more thermocouples. During printing, the fuses heat up, the ink boils (an air bubble is produced) and "fired" onto the paper. I repeat, I have described it in a very simplified way.

What happens if there is no ink in the nozzles? The thermocouples will still heat up. And the ink in the nozzles is also used as a coolant. Overheating will occur - the tubes (nozzles) are deformed and / or some of the thermoelements will fail.

After that, the cartridge will print poorly in some colors, or will not print at all.

I think the answer to the question "How to extend the life of a cartridge?" obvious - you need to make sure that there is always ink in it.

But what about those who refuel the cartridges? After all, after the first refueling, it no longer shows the ink level. There is a simple rule of thumb. If you need to print something, but you are not sure if you have enough ink -. It will not be worse. And, perhaps, by this you will save him.

If you expect your cartridge to last forever with this advice, then you are wrong. It will definitely burn out. Why? Because, according to the manufacturer, it is disposable (the statement does not apply to printheads using ink tanks). The main task of the manufacturer is to make sure that he prints the ink filled from the factory, and then, as soon as possible, fails. Yes, the manufacturer wants to do business on consumables, he also wants to eat :)

But hopefully this article will help your cartridge last longer :)

Any Canon printer or MFP may refuse to work and display an error message with the b200 code on the computer screen. But most often this happens with models that have printhead, not cartridges. The manufacturer recommends turning off the printer and contacting the service center.

What's out of order

Although very rare, the only culprit can be one that is out of order from a voltage drop in the network. Sometimes this is determined visually, by swollen capacitors. And if outwardly everything is in order, measure the nominal voltage of the power supply at the connector of the control board. With a working power supply unit, at the moment the printer ON button is pressed (without PG), within a time interval of about 0.5 s, the indicator corresponds to the norm (usually 24 and 32 V). You can also connect the PSU to another working Canon device for testing. It is not recommended to do the opposite, a new power supply unit may burn out if the printer fails along with it:

- printhead;

- control board.

In the case when the power supply unit is serviceable, you need to remove the steam generator. If the b200 error message still appears on the computer screen of the Canon printer, no doubt it is out of order control board... However, more often than not, the controller burns out along with the print head and replacing only this part is unlikely to solve the problem. In addition, the cost of the GHG and the control board is together comparable to the price of a new Canon device and will most likely still have to buy a printer.

But, after extracting the PG, the error may disappear, and the message that appears requires you to install it. Therefore, the control board is in good working order, but it is impossible to give a 100% guarantee. There are times when a new printhead burns out together with the controller. However, there is still a chance that the b200 code concerned only the PG, and the control board is working properly.

How to get the scanner to work

If this is a Canon multifunction device, for example, consider how to resolve the b200 error and use only scanner.

The Canon controller in working condition polls the head sensors and, if at least one of them fails, diagnoses the entire system as inoperative, reporting an error. The figure shows which PG contacts are responsible for printing certain cartridges. For example, the steam in the green frame corresponds to the Cyan and Magenta ink nozzles, 1pl and 2pl fine droplets. Focusing on the picture, you need glue all contacts enclosed by rectangles, including dotted ones, with insulating tape (you cannot use scotch tape).

Now the controller does not receive any signals about the malfunction of any heaters and sensors and accepts the printhead as good, and the b200 warning disappears. This means that it was the steam generator that failed, and everything is in order with the control board. You can scan.

However, Canon repair technicians claim that if the printer had an error with the code b200, the controller was damaged. Even if it is not out of order yet, it will happen in the near future.

Printing with individual cartridges

Continuing to study the malfunction, we remove one piece of electrical tape and each time we install the head into the printer. If the error code B200 does not appear, we continue to peel off. When the error occurs, we return the last piece of electrical tape to its place. Thus, faulty nozzles will remain sealed, and some cartridges will print:

- only black;

- drops of 1 and 2 pl;

- drops of 5 pl.

Sometimes, after a few days or hours, the printer stops showing the error message and starts working normally. This happens because the peeled and bridged conductors did not burn out the previous time, as is usually the case. The protection system was triggered and the power supply to the steam generator was cut off. The Canon iX6840 device can work without error b200 for several months, or when it is turned on again, the dangling conductors will close again.

Error prevention

It happens that a power supply unit, SG or controller burns out as a result of voltage surges. It is recommended to use one capable of adjusting the voltage and frequency of the output network. However, in the overwhelming majority of cases, an error with the B200 code appears in the message as a result of overheating and the final failure of Canon equipment, which occurs after:

- printing with empty cartridges;

- refills with low-quality ink;

- installation not dry after.

It is difficult to keep track of the ink level in an opaque original cartridge. It may be worth keeping the ink level control function on. Especially if the whole family prints on the printer without checking if the cartridges are full. (Continuous Ink Supply System). However, in any case, it should be remembered that Canon printers cannot work without interruption, from time to time they need rest for 15 minutes.

Every owner of a Canon inkjet printer (regardless of its model) sooner or later encounters the B200 error, which occurs a little more often with devices that use not cartridges, but a print head. Ways to solve this error will be described below, so that you can solve the breakdown yourself, without calling the master at home. But we ask you to be careful and careful with your technique. When this error occurs, the manufacturer Canon recommends turning off the device and contacting the nearest service center in your city. As you can imagine, it is profitable for them, but not for us. And so let's deal with this problem together.

We urge you to read the article to the end. This error is not easy and requires testing. Therefore, take a piece of paper with a pen and write down our recommendations. Perhaps you forget to do some method, and then you already have to go to the service center. At the bottom of this article, there is a selection of videos that will allow you to see clearly how to solve this problem.

Attention! If your printer is under warranty, then don't do anything, close this article, or just read it if you're interested. If you start disassembling the device, then your warranty will be void and you will have to pay for repairs from your entire wallet. So it's best to take your device to the store where you bought the printer and let them decide what to do with your device. Are you out of warranty? Then let's get down to reading this article.

| Canon error b200 |

The first possible solution to this situation is simply to remove the ink cartridges for a while. You should take them out for about an hour and turn off the printer as well. Then you need to move the printer carriage to the center and turn it off.

As you unplug the printer and remove the cartridges, the printer will cool slightly and it is even better if you unplug the printer so that no electricity continues to flow through it.

When this happens, there is the possibility of damage to the cartridges and burnout of the printer circuitry. Read the Inkjet Cartridge Electronic Circuit Care Guidelines. If you have any problems on this topic, please contact us via the comment on this article.

If you follow this procedure and put the cartridges back, but the problem persists, carefully inspect the connectors on the cartridges and you will see that they are burned out. ... see the illustration of the cartridge connectors.

The second possible solution has to do with the printhead and the carriage that moves the ink cartridges. We know that the printer carriage can sometimes be a problem for it. The problem is that the GHGs are filling with ink, so it is recommended to clean the printer connectors. If you need help, just leave a comment on this article and we'll be happy to answer you.