The matrix is \u200b\u200bthe main structural element of the camera and one of the key parameters taken into account by the user when choosing a camera. Matrices of modern digital cameras can be classified according to several signs, but the main and most common is even the division of matrices by charge sensing method, on: matrices CCD type and CMOS matrices. In this article, we will consider the principles of operation, as well as the advantages and disadvantages of these two types of matrices, since they are commonly used in modern photo and video equipment.

CCD matrix

The matrix CCD also called CCD (Devices with Charging Connection). CCD the matrix is \u200b\u200ba rectangular plate of photosensitive elements (photodiodes) located on a semiconductor silicon crystal. The principle of its action is based on the line-by-line movement of charges that have accumulated in the gaps formed by photons in silicon atoms. That is, when colliding with a photodiode, a photon of light is absorbed and an electron is released (an internal photoelectric effect occurs). As a result, a charge is formed, which must be somehow stored for further processing. For this purpose, a semiconductor is embedded in the silicon substrate of the matrix, above which a transparent polycrystalline silicon electrode is located. And as a result of applying an electric potential to this electrode in the depletion zone under the semiconductor, a so-called potential well is formed, in which the charge received from photons is stored. When the electric charge is read from the matrix, the charges (stored in potential wells) are transferred along the transfer electrodes to the edge of the matrix (serial shift register) and towards the amplifier, which amplifies the signal and transmits it to the analog-to-digital converter (ADC), from where the converted signal is sent to the processor, which processes the signal and saves the resulting image to the memory card .

For the manufacture of CCD matrices, polysilicon photodiodes are used. Such matrices are small in size and allow you to get high-quality photos when shooting with normal lighting.

Advantages of CCDs:

- The matrix design provides a high density of photocells (pixels) on the substrate;

- High efficiency (the ratio of registered photons to their total number is about 95%);

- High sensitivity;

- Good color rendering (with sufficient lighting).

Disadvantages of CCDs:

- High noise level at high ISO (at low ISO, noise level is moderate);

- Low operating speed in comparison with CMOS matrices;

- High power consumption;

- More complex technology for reading the signal, since many control microcircuits are needed;

- Manufacturing is more expensive than CMOS sensors.

CMOS matrix

The matrix CMOS, or CMOS sensor (Complementary Metal Oxide Semiconductors) uses active point sensors. Unlike CCDs, CMOSs \u200b\u200bcontain a separate transistor in each photosensitive element (pixel) so that charge conversion is performed directly in the pixel. The resulting charge can be read from each pixel individually, so there is no need for charge transfer (as it happens in CCDs). Pixels CMOS sensor integrates directly with an A / D converter or even a processor. The result of this smart technology is energy savings due to shorter process chains compared to CCDs, as well as a cheaper device due to a simpler design.

A brief principle of operation of a CMOS sensor: 1) Before shooting, a reset signal is sent to the reset transistor. 2) During exposure, light penetrates through the lens and filter onto the photodiode and, as a result of photosynthesis, a charge accumulates in the potential well. 3) Read the value of the received voltage. 4) Data processing and image saving.

Advantages of CMOS Arrays:

- Low power consumption (especially in standby modes);

- High performance;

- Requires less production costs, due to the similarity of technology with the production of microcircuits;

- Unity of technology with other digital elements, which allows combining analog, digital and processing parts on one crystal (i.e., in addition to capturing light in a pixel, you can convert, process and remove noise from the signal).

- The ability to randomly access each pixel or group of pixels, which can reduce the size of the captured image and increase the read speed.

Disadvantages of CMOS sensors:

- The photodiode occupies a small pixel area, as a result, a low light sensitivity of the matrix is \u200b\u200bobtained, but in modern CMOS matrices this minus is practically eliminated;

- The presence of thermal noise from heating transistors inside the pixel during the readout process.

- Relatively large dimensions, fluorine equipment with this type of matrix is \u200b\u200bdistinguished by its large weight and dimensions.

In addition to the aforementioned types, there are also three-layer matrices, each layer of which is a CCD. The difference is that the cells can simultaneously perceive three colors, which are formed by dichroid prisms when a beam of light hits them. Then each beam is directed to a separate matrix. As a result, the brightness of blue, red and green colors is immediately detected on the photocell. Three-layer matrices are used in high-level video cameras, which have a special designation - 3CCD.

Summing up, I would like to note that with the development of technologies for the production of CCD and CMOS matrices, their characteristics also change, so it is more and more difficult to say which of the matrices is definitely better, but at the same time, CMOS matrices are becoming more and more popular in the production of SLR cameras. Based on the characteristic features of various types of matrices, you can get a clear idea why professional photographic equipment that provides high quality filming is rather bulky and heavy. This information must be remembered when choosing a camera - that is, take into account the physical dimensions of the matrix, and not the number of pixels.

What is a CCD?

A bit of history

Previously, photographic materials were used as a light receiver: photographic plates, photographic film, photographic paper. Later, television cameras and photomultiplier tubes (photomultiplier tubes) appeared.

In the late 60s - early 70s, the so-called "Charge Coupling Devices" began to be developed, which is abbreviated as CCD. In English, it looks like "charge-coupled devices" or CCD for short. In principle, CCDs were based on the fact that silicon is capable of responding to visible light. And this fact led to the idea that this principle can be used to obtain images of luminous objects.Astronomers were among the first to recognize the extraordinary ability of the CCD to capture images. In 1972, a group of researchers from JPL (Jet Propulsion Laboratory, USA) established a CCD development program for astronomy and space research. Three years later, in collaboration with scientists from the University of Arizona, the team acquired the first astronomical CCD image. In the near-infrared image of Uranus, using a 1.5-meter telescope, dark spots near the planet's south pole were found, indicating the presence of methane there ...

The use of CCD-matrices today has found wide application: digital cameras, video cameras; It has become possible to embed CCD-matrix as cameras even in mobile phones.

CCD device

A typical CCD device (Fig. 1): on the semiconductor surface there is a thin (0.1-0.15 μm) layer of dielectric (usually oxide), on which strips of conducting electrodes (made of metal or polycrystalline silicon) are located. These electrodes form a linear or matrix regular system, and the distances between the electrodes are so small that the effects of the mutual influence of neighboring electrodes are significant. The principle of CCD operation is based on the generation, storage and directional transfer of charge packets in potential wells formed in the near-surface layer of a semiconductor when external electric voltages are applied to the electrodes.

Figure: 1. The basic structure of the CCD matrix.In fig. 1, C1, C2 and C3 denote MOS capacitors (metal-oxide-semiconductor).

If a positive voltage U is applied to any electrode, then an electric field arises in the MIS structure, under the action of which the majority carriers (holes) very quickly (in a few picoseconds) leave the semiconductor surface. As a result, a depletion layer is formed at the surface, the thickness of which is fractions or units of a micrometer. Minority carriers (electrons) generated in the depleted layer under the action of any processes (for example, thermal) or that got there from the neutral regions of the semiconductor under the action of diffusion will move (under the action of the field) to the semiconductor-insulator interface and localize in a narrow inverse layer. Thus, a potential well for electrons arises at the surface, into which they roll from the depletion layer under the action of the field. The majority carriers (holes) generated in the depletion layer are ejected into the neutral part of the semiconductor under the action of the field.

During a given time interval, each pixel is gradually filled with electrons in proportion to the amount of light that has entered it. At the end of this time, the electric charges accumulated by each pixel are transmitted in turn to the "output" of the device and measured.The size of the photosensitive pixel of the matrices is from one to two to several tens of microns. The size of the silver halide crystals in the photosensitive layer of the photographic film ranges from 0.1 (positive emulsions) to 1 micron (highly sensitive negative).

One of the main parameters of the matrix is \u200b\u200bthe so-called quantum efficiency. This name reflects the efficiency of conversion of absorbed photons (quanta) into photoelectrons and is similar to the photographic concept of photosensitivity. Since the energy of light quanta depends on their color (wavelength), it is impossible to unambiguously determine how many electrons will be born in a matrix pixel when it absorbs, for example, a flux of one hundred dissimilar photons. Therefore, the quantum efficiency is usually given in the passport for the matrix as a function of the wavelength, and in some parts of the spectrum it can reach 80%. This is much more than a photographic emulsion or an eye (approximately 1%).

What are the types of CCDs?

If the pixels are lined up in one row, then the receiver is called a CCD ruler, if the surface area is filled with even rows, then the receiver is called a CCD matrix.

The CCD ruler had a wide range of applications in the 80s and 90s for astronomical observations. It was enough to hold the image on the CCD line and it appeared on the computer monitor. But this process was accompanied by many difficulties, and therefore, at present, CCD arrays are increasingly being replaced by CCDs.

Unwanted effects

One of the unwanted side effects of charge transfer on the CCD that can interfere with observations is bright vertical stripes (pillars) in place of bright areas in a small area of \u200b\u200bthe image. Also, the possible undesirable effects of CCD matrices include: high dark noise, the presence of "blind" or "hot" pixels, uneven sensitivity across the matrix field. To reduce dark noise, autonomous cooling of CCD matrices is used to temperatures of -20 ° C and below. Or, a dark frame is taken (for example, with a closed lens) with the same duration (exposure) and temperature as the previous frame was taken. Subsequently, a dark frame is subtracted from the image by a special program on the computer.

The great thing about CCD TV cameras is that they can capture images at up to 25 frames per second with a resolution of 752 x 582 pixels. But the unsuitability of some cameras of this type for astronomical observations is that the manufacturer implements internal image preprocessing (read - distortion) in them for better perception of the received frames by vision. This is AGC (automated control adjustment), and the so-called. the effect of "sharp borders" and others.

Progress…

In general, the use of CCD receivers is much more convenient than the use of non-digital light receivers, since the obtained data immediately appear in a form suitable for processing on a computer and, in addition, the speed of obtaining individual frames is very high (from several frames per second to minutes).

At the moment, the production of CCDs is developing and improving at a rapid pace. The number of "megapixels" of matrices increases - the number of individual pixels per unit area of \u200b\u200bthe matrix. The quality of images obtained using CCDs, etc. is improved.

Used sources:

1. 1. Victor Belov. Accurate to tenths of a micron.

2. 2. S.E. Guryanov. Meet - CCD.

For the first time, the CCD principle with the idea of \u200b\u200bstoring and then reading electronic charges was developed by two engineers of the BELL corporation in the late 60s in the course of searching for new types of memory for computers that could replace memory on ferrite rings (yes, there was such a memory). This idea turned out to be unpromising, but the ability of silicon to respond to the visible spectrum of radiation was noticed and the idea of \u200b\u200busing this principle for image processing was developed.

Let's start by deciphering the term.

The abbreviation CCD stands for Charge-Coupled Devices, a term derived from the English Charge-Coupled Devices (CCD).

This type of device currently has a very wide range of applications in a wide variety of optoelectronic devices for image registration. In everyday life, these are digital cameras, camcorders, various scanners.

What makes a CCD receiver different from a conventional semiconductor photodiode, which has a photosensitive area and two electrical contacts for picking up an electrical signal?

First of all There are a lot of such light-sensitive areas (often called pixels - elements that receive light and convert it into electrical charges) in a CCD receiver, from several thousand to several hundred thousand or even several million. The sizes of individual pixels are the same and can range from units to tens of microns. The pixels can be lined up in one row - then the receiver is called a CCD ruler, or even rows to fill a section of the surface - then the receiver is called a CCD matrix.

The location of the light receiving elements (blue rectangles) in the CCD array and CCD matrix.

Secondly , in a CCD receiver, which looks like an ordinary microcircuit, there is no huge number of electrical contacts for outputting electrical signals, which, it would seem, should come from each light-receiving element. On the other hand, an electronic circuit is connected to the CCD receiver, which makes it possible to extract from each photosensitive element an electrical signal proportional to its exposure.

The action of a CCD can be described as follows: each photosensitive element - a pixel - acts like a piggy bank for electrons. Electrons are generated in pixels by light from a source. Over a given time interval, each pixel is gradually filled with electrons in proportion to the amount of light that has entered it, like a bucket exposed to the street in the rain. At the end of this time, the electric charges accumulated by each pixel are transmitted in turn to the "output" of the device and measured. All this is possible due to the specific structure of the crystal, where the light-sensitive elements are located, and the electrical control circuit.

The CCD works in much the same way. After exposure (illumination by the projected image), the electronic control circuit of the device supplies it with a complex set of impulse voltages, which begin to shift the columns with electrons accumulated in pixels to the edge of the matrix, where there is a similar measuring CCD register, the charges in which are already shifted in the perpendicular direction and fall to the measuring element, creating signals in it proportional to the individual charges. Thus, for each subsequent moment in time, we can get the value of the accumulated charge and figure out which pixel on the matrix (row number and column number) it corresponds to.

Briefly about the physics of the process.

To begin with, we note that CCDs belong to the products of so-called functional electronics. They cannot be represented as a collection of individual radioelements - transistors, resistors and capacitors. The work is based on the principle of charge coupling. The principle of charge coupling uses two positions known from electrostatics:

- like charges repel,

- charges tend to be located where their potential energy is minimal. Those. roughly - "the fish is looking where it is deeper."

First, imagine a MOS capacitor (MOS is short for metal oxide semiconductor). This is what remains of the MOS transistor, if you remove the drain and source from it, that is, just an electrode separated from silicon by a dielectric layer. For definiteness, we will assume that the semiconductor is p-type, that is, the concentration of holes in equilibrium conditions is much (several orders of magnitude) higher than that of electrons. In electrophysics, a "hole" is a charge reciprocal to the charge of an electron, i.e. positive charge.

What happens if a positive potential is applied to such an electrode (it is called a gate)? The electric field created by the gate, penetrating into the silicon through the dielectric, repels the movable holes; a depletion region appears - a certain volume of silicon free of major carriers. With the parameters of semiconductor substrates typical for CCDs, the depth of this region is about 5 μm. On the contrary, the electrons generated here under the action of light will be attracted to the gate and will accumulate at the oxide-silicon interface directly under the gate, that is, they fall into the potential well (Fig. 1).

Figure: 1

Formation of a potential pit when voltage is applied to the gate

In this case, the electrons, as they accumulate in the well, partially neutralize the electric field created in the semiconductor by the gate, and in the end can completely compensate for it, so that the entire electric field will fall only on the dielectric, and everything will return to its original state - with the exception that a thin layer of electrons is formed at the interface.

Suppose now another gate is located next to the gate, and a positive potential is also applied to it, and more than the first one (Fig. 2). If only the gates are close enough, their potential wells merge, and electrons in one potential well move to the neighboring one, if it is "deeper".

Figure: 2

Overlapping of potential holes of two closely spaced gates. The charge flows to the place where the potential hole is deeper.

It should now be clear that if we have a chain of gates, then, by applying appropriate control voltages to them, it is possible to transfer a localized charge packet along such a structure. A remarkable feature of the CCD - the self-scanning property - is that only three clock buses are enough to control a gate chain of any length. (The term bus in electronics is a conductor of electric current that connects elements of the same type, a clock bus is conductors along which a phase-shifted voltage is transmitted.) Indeed, for the transfer of charge packets, three electrodes are necessary and sufficient: one transmitting, one receiving and one insulating, separating pairs receiving and transmitting from each other, and the electrodes of the same name of such triplets can be connected to each other in a single clock bus, requiring only one external output (Fig. 3).

Figure: 3

The simplest three-phase CCD register.

The charge in each potential well is different.

This is the simplest three-phase shift register on a CCD. The clock diagrams of the operation of such a register are shown in Fig. 4.

Figure: 4

The clock diagrams for controlling a three-phase register are three meanders shifted by 120 degrees.

When the potentials change, the charges move.

It can be seen that for its normal operation at every moment of time, at least one clock bus must have a high potential, and at least one - a low potential (barrier potential). When the potential on one bus increases and it decreases on the other (previous), all charge packets are simultaneously transferred under the adjacent gates, and for a full cycle (one cycle on each phase bus), the charge packets are transferred (shifted) to one register element.

To localize the charge packets in the transverse direction, the so-called stop channels are formed — narrow strips with an increased concentration of the main dopant along the transfer channel (Fig. 5).

Figure: five.

Top view of the register.

The transfer channel in the lateral direction is limited by stop channels.

The fact is that the concentration of the dopant determines the specific voltage at the gate underneath the depletion region (this parameter is nothing more than the threshold voltage of the MOS structure). From intuitive considerations, it is clear that the higher the impurity concentration, i.e., the more holes in the semiconductor, the more difficult it is to drive them back into the depth, i.e., the higher the threshold voltage or, at one voltage, the lower the potential in the potential well.

Problems

If, in the production of digital devices, the spread of parameters over the plate can reach several times without a noticeable effect on the parameters of the resulting devices (since the work is carried out with discrete voltage levels), then in a CCD, a change in, say, the concentration of dopant by 10% is already noticeable in the image. The size of the crystal and the impossibility of redundancy, as in LSI memory, add its problems, so that defective areas lead to the unusability of the entire crystal.

Outcome

Technologically, different CCD pixels have different sensitivity to light and this difference must be corrected.

In digital CMAs, this correction is called Auto Gain Control (AGC).

How the AGC system works

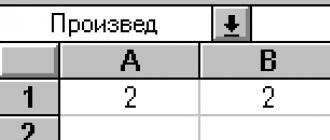

For ease of consideration, we will not take something specific. Suppose there are some potential levels at the output of the ADC of the CCD node. Let's say 60 is the average white level.

- For each pixel of the CCD line, a value is read when it is illuminated with a reference white light (and in more serious devices - and reading the "black level").

- The value is compared with a reference level (eg average).

- The difference between the output value and the reference level is stored for each pixel.

- Later, during scanning, this difference is compensated for for each pixel.

The AGC system is initialized every time the scanner system is initialized. You've probably noticed that when you turn on the machine, after a while the scanner carriage begins to make forward-reverse movements (crawl around the b / w strips). This is the initialization process for the AGC system. The system also takes into account the condition of the lamp (aging).

You also probably noticed that small MFPs equipped with a color scanner “light the lamp” in three colors in turn: red, blue and green. Then, only the original light turns white. This is done for better correction of the matrix sensitivity separately for RGB channels.

Halftone test (SHADING TEST) allows you to initiate this procedure at the request of the engineer and bring the correction values \u200b\u200bto real conditions.

Let's try to consider all this on a real, "combat" machine. Let's take a well-known and popular device as a basis. SAMSUNG SCX-4521 (Xerox Pe 220).

It should be noted that in our case CCD becomes CIS (Contact Image Sensor), but the essence of what is happening does not fundamentally change. Just as a light source, LED strips are used.

So:

The image signal from CIS has a level of about 1.2 V and is fed to the ADC section (SADC) of the apparatus controller (SADC). After SADC, the analog CIS signal will be converted to an 8-bit digital signal.

The image processor in SADC primarily uses the tone correction function, and then the gamma correction function. After that, the data is fed to various modules in accordance with the operating mode. In Text mode, image data goes to the LAT module, in Photo mode, image data goes to the "Error Diffusion" module, and in PC-Scan mode, image data goes directly to a personal computer via DMA access.

Place several blank sheets of white paper on the exposure glass before testing. It goes without saying that the optics, b / w stripe and, in general, the scanner unit from the inside must be previously "licked"

- Select in TECH MODE

- Press the ENTER button to scan the image.

- After scanning, "CIS SHADING PROFILE" will be printed. An example of such a sheet is shown below. It does not have to be a copy of your result, but it is close in image.

- If the printed image is very different from the image shown in the figure, then the CIS is defective. Pay attention - at the bottom of the report sheet it says “Results: OK”. This means that the system has no serious complaints about the CIS module. Otherwise, error results will be given.

Example of profile printout:

Good luck to you!!

The materials of articles and lectures of teachers from St. Petersburg State University (LSU), St. Petersburg Electrotechnical University (LETI) and Axl are taken as a basis. Thanks to them.

Material prepared by V. Shelenberg

(lang: ‘ru’)

I continue the conversation about the device started in the previous publication.

One of the main elements of a digital camera that distinguishes it from film cameras is a photosensitive element, the so-called image intensifier tube or photosensitive digital camera... We have already spoken about camera matrices, but now let us consider the device and the principle of the matrix operation in more detail, although it is rather superficial so as not to tire the reader too much.

Most digital cameras nowadays are equipped with CCD matrices.

CCD-matrix. Device. Principle of operation.

Let's take a look at the device CCD sensors.

Semiconductors are known to be divided into n-type and p-type semiconductors. In an n-type semiconductor there is an excess of free electrons, and in a p-type semiconductor there is an excess of positive charges, "holes" (and hence a lack of electrons). All microelectronics is based on the interaction of these two types of semiconductors.

So, the element Digital camera CCD is arranged as follows. See Figure 1:

Fig. 1

Fig. 1

Without going into details, then a CCD element or a charge-coupled device, in English transcription: charge-coupled-device - CCD, is a MIS (metal-dielectric-semiconductor) capacitor. It consists of a p-type substrate - a silicon layer, a silicon dioxide insulator and electrode plates. When a positive potential is applied to one of the electrodes, a zone depleted in major carriers - holes, is formed under it, since they are pushed aside by the electric field from the electrode deep into the substrate. Thus, a potential well is formed under this electrode, that is, the energy zone is favorable for the movement of minority carriers - electrons into it. A negative charge accumulates in this pit. It can be stored in this well for a long time due to the absence of holes in it and, therefore, the reasons for the recombination of electrons.

In photosensitive matrices the electrodes are films of polycrystalline silicon, transparent in the visible region of the spectrum.

Photons of light incident on the matrix fall into the silicon substrate, forming a hole-electron pair in it. Holes, as mentioned above, are displaced into the depth of the substrate, and electrons are accumulated in the potential well.

The accumulated charge is proportional to the number of photons falling on the element, i.e. to the intensity of the light flux. Thus, a charge relief corresponding to the optical image is created on the matrix.

Movement of charges in the CCD matrix.

Each CCD element has several electrodes to which different potentials are applied.

When a potential higher than that on the given electrode is applied to the adjacent electrode (see Fig. 3), a deeper potential well is formed under it, into which the charge moves from the first potential well. In this way, the charge can move from one CCD cell to another. The CCD element shown in Fig. 3 is called three-phase, there are also 4-phase elements.

Fig. 4. Scheme of operation of a three-phase device with a charge coupled - a shift register.

Fig. 4. Scheme of operation of a three-phase device with a charge coupled - a shift register.

To convert charges into current pulses (photocurrent), serial shift registers are used (see Fig. 4). This shift register is a string of CCD elements. The amplitude of the current pulses is proportional to the amount of charge transferred, and thus proportional to the incident luminous flux. The sequence of current pulses generated by reading the sequence of charges is then fed to the amplifier input.

Rows of closely spaced CCD elements are combined into CCD... The work of such a matrix is \u200b\u200bbased on the creation and transfer of a local charge in potential wells created by an electric field.

Fig. 5.

Fig. 5.

The charges of all CCD elements of the register are synchronously moved to adjacent CCD elements. The charge that was in the last cell is fed to the output from the register, and then fed to the input of the amplifier.

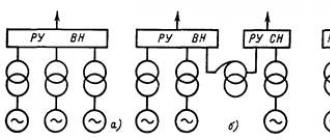

The serial shift register is charged with perpendicularly spaced shift registers, collectively referred to as a parallel shift register. The parallel and sequential shift registers make up the CCD matrix (see Fig. 4).

Shift registers perpendicular to the serial register are called columns.

The movement of charges in the parallel register is strictly synchronized. All charges of one row are shifted simultaneously to the next. The charges of the last line go into a sequential register. Thus, in one working cycle, the line of charges from the parallel register enters the input of the sequential register, freeing up space for the newly formed charges.

The work of the serial and parallel registers is synchronized by a clock generator. Part digital camera matrix also includes a microcircuit that supplies potentials to the register transfer electrodes and controls their operation.

The image intensifier tube of this type is called a full-frame CCD-matrix. For its operation, it is necessary to have an opaque cover, which first opens the image intensifier for exposure to light, then, when it receives the number of photons necessary to accumulate a sufficient charge in the matrix elements, closes it from light. Such a cover is a mechanical shutter, as in film cameras. The absence of such a shutter leads to the fact that when the charges move in the shift register, the cells continue to be irradiated with light, adding extra electrons to the charge of each pixel that do not correspond to the luminous flux of a given point. This leads to "smearing" of the charge, respectively, to the distortion of the resulting image.