Hello. Let's talk how to choose cooling for a computer, more precisely for a processor.

In general, any weather (in the winter - batteries, in the summer - the sun) is a difficult time for our computer, because the ambient temperature (and, as a consequence, of computer components) rises significantly, and therefore the cooling systems have to work to their fullest, trying to cool the ardent character of our iron friends.

However, standard coolers do not always successfully cope with their task, which leads to constant reboots, shutdowns and other problems that follow computer overheating.

As you probably remember, the article "" will help you identify overheating (and find out the temperatures of components in general), and today I will tell you how to choose the right cooler for, which, as a rule, has the hardest time.

Why you need to take a separate processor cooling system

To begin with, I would like to explain a little why the processor needs cooling and what is bad about the twist that is usually given in addition to the crystal (you mean this very processor). No, seriously, it was impossible to do without this part, because I am very often asked why the option that comes with the processor is so bad, because, they say, they are not fools and know what to put in the kit. I certainly do not argue that the computer works with such a cooling system, but there are still a number of nuances.

In very simple terms, a processor is made up of a huge number of small electrical conductors, each of which needs energy. And, as you know from the school physics course, the energy from the conductor does not disappear anywhere - it goes from electrical to heat.

Considering that there are more than half a billion transistors in a modern processor, the question of the need for cooling disappears by itself: there is enough heat from them to heat a small room. The processor cannot independently dissipate such an amount of energy: the area is small, and the materials are not the same.

Therefore, with each crystal, manufacturers supply a simple cooler (if, of course, you buy BOXprocessor version, not OEM). It is enough to work at standard frequencies and at normal temperatures, but for extreme situations (long warm-up, i.e., work with a full-fledged processor-dependent application or game, high ambient temperatures (summer), overclocking, etc.), it is better to look for a more powerful model.

The fact is that under this most unpretentious cooler supplied in the kit, the processor is noticeably hot. No, the temperature does not reach critical, but it does not matter steadilyhigh, and because of it, some chemical processes that continuously occur in the crystal are accelerated, as a result of which, firstly, it can break down corny faster, and secondly, it slows down and skips cycles. The main problem lies precisely in the fact that the processor has a weak cooling system .. mmm .. a small performance margin. Look up all sorts of tables of results on the Internet.

Even in a room with air conditioning, the temperature of the crystal under a standard twist rises to 73 degrees (and this is when the stand is open, that is, without the case). In the case, where hard disks, video cards, floppy drives, etc. live in the neighborhood, the air can heat up under 60 degrees and the higher this temperature, the harder it is for the cooler, and the hotter the ambient air, the more the performance drops.

However, you shouldn't go to the store and buy the first cooler you find. In the world of cooling, sometimes a device is 3000 rubles may well be worse than the model for 1000 rubles and this is due to many factors, which we will now talk about.

Part 1: cooler base

Well, let's get started.

The work of any cooler begins .. at its base, namely, in the place where it comes into contact with the processor. Here the cooler takes heat from it and transfers it to the cooling area. This process is called heat transfer, and its efficiency depends on two variables - surface area and surface material.

Do you want to know and be able to do more yourself?

We offer you training in the following areas: computers, programs, administration, servers, networks, site building, SEO and more. Find out the details now!

It is usually unrealistic to come up with something super-duper here, because the dimensions of the processor are fixed, that is, the contact area cannot be increased, and there is only one material that is affordable and of high-quality thermal conductivity - copper (there is of course also aluminum, but it is less effective).

Hence, it turns out that the maximum that a manufacturer can do is to do so that, with all other components, heat transfer is carried out as efficiently as possible, namely .. the base must be perfectly polished.

Therefore, one of the first selection criteria is the "specularity" of the metal in the area of \u200b\u200bcontact with the processor, that is, ideally, you should see your reflection on the surface, or at least not observe any significant irregularities or, especially, scratches, because these reduce contact area and reduce work efficiency.

Also, beware of heat pipes "tearing" the base of the cooler (see the photo above), as they also reduce the usable area of \u200b\u200bcontact. If you see that the tubes protrude from the total surface area, then it is better to put aside such a cooler and look for something else.

But what you rarely need to pay attention to (a common mistake of beginners who believe that color always determines the material) is the color, because copper is often plated with nickel.

Part 2: heat pipes

The next stage of work is the transfer of heat to the cooling surfaces. When the processors were weak and cold, there was no such stage: the radiator was attached directly to the base and dissipated heat into the air. With the increase in performance and the amount of energy released, heat transfer began to be taken more seriously - heat-conducting pipes appeared on the coolers.

This invention is old and well known to many. One end of a copper pipe is sealed, liquid is poured into it, air is pumped out and the other end is sealed. When heated, water absorbs energy and turns into steam, which rises to the upper (cold) part of the pipe, cools, condenses with the release of stored energy and flows down. And so on ad infinitum.

In coolers everything is the same, but with one caveat. When installed in the case, the cooling system is in a horizontal position, and water cannot independently drain into the heating zone. Therefore, the tubes are packed with porous material. Thanks to the action of the capillary effect, the liquid can move against the forces of gravity and move in any direction.

It is also difficult to come up with something new at this stage, because the operation of heat pipes practically does not depend on their physical parameters, and therefore, as a criterion, one should rely on the number of heat pipes. Globally, the more, the better, but in general, as a minimum, three or four will do (less is already doubtful).

Part 3: body and components

The next phase of the cooler's operation is heat dissipation. This action takes place on the fins of the heatsink, namely, dozens of plates strung on heat pipes. It is here that the heat taken from the processor will be given to the air and it will be able to breathe more freely. The radiator can look whatever you want - the developers are not shy about experimenting with shapes, tilt angles, materials, and so on, but all this joy obeys a number of rules, which are the next criteria for choosing.

First, the dissipation area should be as large as possible, that is, the radiator fins should be as large as possible, and the radiator itself should be as massive as possible. Secondly, the thinner the plates, the better, because the heat will be retained less. The requirements for the material of this whole case are the same - high thermal conductivity, that is, copper should act as it. Some say that, they say, copper is not required at this phase and it is important to use it exclusively in the base and heat pipes, because given the high dissipation area, the radiator can be taken from aluminum too .. However, I do not really agree with this statement and I think that even here it is better to choose copper as the material. But see for yourself.

Part 4: active cooling, namely the fan itself

Well, the last stage of the cooling system for the processor is active cooling, that is, the spinner itself. No matter what the manufacturers say, a radiator with a powerful processor cannot cope alone - the limitation of the available area and high thermal resistance (temperature drop by one watt of heat dissipated) will not allow.

Again, the use of a radiator alone is questionable due to the low emission of dissipated heat from the case, which leads to an increase in temperature in the case and heating of other elements inside it.

The fan naturally helps to overcome such problems: the generated powerful air flow reduces the resistance of the radiator and increases the amount of heat removed.

The rule for turntables is simple: you need to look for the largest ones (and not, contrary to the opinion of beginners, the number of revolutions). The larger the impeller diameter, the more air is taken in one revolution, which means that the required rotation speed and, as a result, noise decreases.

You take a turntable 120 mm from 1200 revs and turntable 80 mmfrom 2400 and comparing these, we get that the first is, firstly, more efficient, and secondly, much quieter.

By the way, in addition to the size and number of revolutions, you must also monitor the type of bearing. If written " Ball bearing"(rolling), - we take, because they are quiet and last a long time. If" Slide bearning"(sliding) - put off, because they make noise and quickly" turn sour ".

Part 5: choosing thermal paste

When buying a cooler, don't forget about thermal grease. In expensive and good coolers, this is usually included in the kit or is already applied to the surface, but for the rest it is still worth buying separately.

What is thermal paste? This is a layer of paste (just like a toothpaste), the purpose of which, when applied to the surface between the processor and the base of the cooler, is to eliminate the unevenness of the contacting surfaces and remove all air between them. Good thermal paste may well bring down the temperature by 5-10 degrees.

Unfortunately, there are almost no sensible comparative tests of pastes, and those that are being made do not correspond to reality. The fact is that to get into working mode, the paste needs about 200 hours, and no one will spend so much time on each tube, as you understand. So it is necessary to choose this according to the technical characteristics. The most important parameter is thermal conductivity. The higher the better.

Globally, I sort of covered all the main points and forgot nothing. Probably not in more detail :)

As always, if you have any questions, you want to add or say something, then write in the comments to the same article.

By the way, do not forget that dust often accumulates between the fins of the radiator and it needs to be cleaned, which I wrote about in the article. ”There, by the way, there are a few words about choosing the right case.

As always, if you have any questions, thoughts, additions and all that stuff, then welcome to the comments to this article.

- PS2: I wrote a few words about cooling video cards.

- PS3: For help in writing this article, thanks to your favorite magazine “ gambling addiction”.

Currently, the most efficient are tower coolers based on copper heat pipes. With proper implementation, three to four heat pipes are enough to provide cooling for any serial processor in the heatsink design. The further increase in the number of pipes in the radiators does not always lead to a decrease in the peak temperatures of the processor, so there is no need to chase after this. The fins of the radiators and the heat pipes themselves are usually nickel plated, which allows them to maintain an almost perfect appearance throughout the entire service life.

When choosing a cooler, you should pay attention to the method of contact of the tubes with the base and radiator fins. If soldering is used (its traces are always clearly visible at the joints), you can entrust your processor with such a device, but simple crimping of plates on tubes and the absence of grooves in the base should be treated with a grain of salt, although soldering is extremely rare in the middle price segment. Coolers with direct contact technology, which have become popular in recent years, are widespread, when the radiator has no base, and its role is played by heat pipes, processed in the base area to a flat surface. In such models, you need to pay attention to the distance between the tubes at the base - the smaller it is, the more uniform the heat exchange will be, which means the cooler will be more efficient.

Heatsink size really matters. The larger the area of \u200b\u200bthe fins and the greater their number, the higher the area of \u200b\u200bthe radiator and the more heat it can dissipate. Do not underestimate the various types of optimization of radiators - the ends of the fins of variable height, staggered tubes, but the effect from evaporation chambers or radial radiators is often minimal.

It is worth mentioning also about coolers of the so-called "top-design", in which the radiator is located parallel to the motherboard, and the fan blows the air flow towards its plane. The height of these coolers is small (no more than 150 mm), however, due to design limitations, their area is relatively small, so their efficiency is usually lower than tower coolers. But the air flow of such coolers better cools the elements of the near-processor space and the heatsinks on the motherboard.

Noise level

If the efficiency of even the simplest air coolers turns out to be quite sufficient for the standard operating modes of processors, then their noise level is far from satisfactory to everyone. The only source of noise in air coolers is the fan. In general, you can focus on the following figures: for 80- and 92-mm fans, the speed should be no higher than 1500-1700 rpm; for 120 mm fans - no higher than 1200-1300 rpm; for 140 mm fans and more - no higher than 1000-1200 rpm.

Almost all currently produced cooling systems are equipped with fans that support automatic speed control, depending on the degree of load on the processor and / or its temperature. Such fans are practically silent at low processor load and at the same time they are sensitive to any increase. The adjustment algorithm is set in the BIOS of the motherboard, or through software.

An important component of the fan is the bearing type. The most common and cheapest is a sleeve bearing, which has a typical life of 30,000 hours, or about 3 years of continuous operation. But in practice, such bearings do not last long, and after half of the service life they begin to make noise. More durable (and expensive) ball bearings, which can last more than 100,000 hours, and with high quality workmanship can maintain low noise levels throughout their life. The compromise option is FDB bearing. They are generally twice as durable as plain bearings and have low noise levels.

Heat dissipation of the processor is one of the main parameters that you should pay attention to when assembling a computer. The CPU is a key component on which the entire system depends. If it overheats, the forced cooling mode will begin, which results in skipping cycles, that is, the appearance of problems with the computer's performance. When the processor cannot cool down even in this way, it starts to shut down automatically so as not to permanently fail. It is probably not worth talking about the dangers of an abrupt shutdown of the computer, moreover, when it happens in an emergency mode of the central processor.

In order for the CPU to maintain an acceptable temperature, it needs additional cooling. That is why it is important to choose the right CPU cooler. There are many nuances that you need to pay attention to when choosing a processor fan, and it is also important not to forget about the main parameters when choosing it.

Why change the included cooler

On sale you can find central processors in OEM and BOX trim levels. In terms of performance, there are no differences between these CPU versions of the same model, and they differ only in the package bundle. The OEM version is only the central processor itself, while the BOX package includes a cooler.

On sale you can find central processors in OEM and BOX trim levels. In terms of performance, there are no differences between these CPU versions of the same model, and they differ only in the package bundle. The OEM version is only the central processor itself, while the BOX package includes a cooler.

Many users who do not have much experience in assembling a computer may get the impression that the ideal solution is to buy a BOX with a processor package, but this is not always the case. The coolers that come with the processor are often of mediocre quality, and they are not able to provide cooling of the "stone" under its high load. That is, if the CPU is purchased for an office computer, where it will not face more difficult tasks than working with a browser and a text editor, then there will be no problems with cooling the processor with a cooler from the BOX package. But if the "stone" is planned to be used in games and other resource-intensive applications, then you need to attend to the purchase of a more powerful cooler.

Modern processors are made up of more than 500 million transistors, each of which heats up during operation. Due to the small area of \u200b\u200bthe CPU, such serious heat cannot be dissipated on its own, and an additional cooler is required to remove it. The more complex tasks are presented to the processor, the more efficient cooling is required.

How to choose the right CPU cooler

The most important thing when choosing a cooler is to match it to the characteristics of the processor. Obviously, the more powerful the processor, the more heat it generates under high load. Accordingly, he needs more cooling. The heat dissipation parameter of the processor is usually denoted as TDP, and it is measured in watts. Paying attention to the heat dissipation of the processor, we must not forget that the models also differ from each other in the type of socket. Now let's consider the selection for each of the parameters in a little more detail.

Processor socket

A socket is a processor size, and it is denoted: AM3 +, 1150, 2011-3 and other combinations of letters and numbers. Manufacturers are trying to standardize CPUs for certain sizes, but due to changes in production technology over time, there are already about a dozen available. A socket is the size of the connector on the motherboard where the rock itself is inserted.

A socket is a processor size, and it is denoted: AM3 +, 1150, 2011-3 and other combinations of letters and numbers. Manufacturers are trying to standardize CPUs for certain sizes, but due to changes in production technology over time, there are already about a dozen available. A socket is the size of the connector on the motherboard where the rock itself is inserted.

Thus, when choosing a cooler for a processor, you should initially find out the processor model and check on the manufacturer's website on the Internet in what standard size it is made. Coolers often fit multiple sockets due to the versatility of the mounts.

CPU heat dissipation

Having decided on the size, you need to look at the heat dissipation of the processor. You can find out information about the TDP parameter of a particular processor on the manufacturer's official website.

Choosing a cooler based on the heat dissipation parameter for a specific processor model is a little more complicated. The fact is that in online stores and on various websites it is quite rare to find accurate information about which cooler is suitable for processors with which TDP. However, renowned processor fan manufacturers, for example, Noctua, do not hesitate to provide such information.

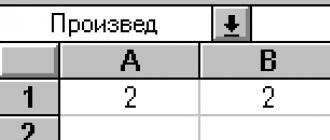

If you cannot find information on a specific cooler model, you can use the data from the table below. Please note that the information in it is very approximate, and it is better to choose the “oversized” processor fan option.

How to choose a quality cooler

Having selected the cooler models by processor parameters, there will still be dozens or even hundreds of fan options that can be purchased. In such a situation, you should look at the reviews about the quality of this or that cooler, left by their owners. But it is better to independently reject the least quality ones from the available options by evaluating the fans according to the following parameters.

Cooler base

The area the cooler touches the processor plays an important role in cooling. Since the dimensions of the "stone" are fixed, it is practically impossible to increase this contact area. At the same time, some cooler manufacturers, in search of innovations, partially remove heat pipes based on the fan. Because of this, the contact area and efficiency of the cooler are reduced.

It is also important that the base is made without various patterns. It should be copper polished to a mirror finish. Before purchasing it is necessary to inspect the cooler so that there are no cuts, irregularities and other defects on its base.

It is also important that the base is made without various patterns. It should be copper polished to a mirror finish. Before purchasing it is necessary to inspect the cooler so that there are no cuts, irregularities and other defects on its base.

Please note: In most cases, the cooler base is made of copper. This material is cost effective and efficient in terms of heat transfer. There are aluminum options, but they are significantly less effective. In this case, the copper can be coated with nickel, which makes it silver in color.

Heat pipes

On almost every modern cooler, you can see several heat pipes, whereas previously they were not used. The fact is that with an increase in the power of processors and an increase in their heat release, the existing cooling standards are no longer enough, and the manufacturers decided to use a proven option - the installation of heat pipes.

On almost every modern cooler, you can see several heat pipes, whereas previously they were not used. The fact is that with an increase in the power of processors and an increase in their heat release, the existing cooling standards are no longer enough, and the manufacturers decided to use a proven option - the installation of heat pipes.

The copper tube is filled with liquid and sealed on both sides. When heated, the liquid heats up and turns into a gaseous state. The gas moves to the other side of the tube and thereby removes heat. The steam then cools down, turns back into water and returns to the base of the tube. In computer coolers, the process happens in much the same way, except that there is also a porous material inside, which is necessary for the liquid to return back, even when the pipes are in a horizontal position.

When choosing a cooler for a processor, you need to pay attention to how many pipes are installed. According to their properties, they do not differ much, depending on the size, therefore the quantity becomes the main criterion. The minimum allowable amount for cooling a modern powerful processor is 3-4 pipes, but the more the better.

Radiator

From the base of the cooler, the heat is transferred to the heatsink, which is made up of dozens of fins fitted over heat pipes.

A radiator can be of any shape, but it is important to remember some rules that distinguish a good option from a bad one:

A radiator can be of any shape, but it is important to remember some rules that distinguish a good option from a bad one:

- The larger the radiator area, the better;

- The plates should be thin, but abundant;

- Better when the radiator is made of copper.

Since the heatsink on the cooler is partially visible in an open computer, some firms try to make it the best possible from a design point of view. It can be of different colors, shapes, plates are made at unusual angles. If the above rules are followed, then the design decisions have little effect on the quality of the cooler.

Fan

Some time ago, in pursuit of quiet computer operation, manufacturers did everything to abandon the active cooling element, that is, the cooler itself. However, a radiator without a heat dissipation element cannot cope with powerful processors, and fans in a processor cooler have not yet been abandoned.

Some time ago, in pursuit of quiet computer operation, manufacturers did everything to abandon the active cooling element, that is, the cooler itself. However, a radiator without a heat dissipation element cannot cope with powerful processors, and fans in a processor cooler have not yet been abandoned.

When choosing a fan, it is necessary to pay attention to its size and, accordingly, to the size of the blades. Coolers with large blades are not only more efficient in terms of removing heat from the radiator, but also quieter. There is a misconception that the rotational speed of the cooler is much more important, but this is not the case. Speed \u200b\u200bis an important parameter, but the diameter of the fan itself is more important. If you install a cooler with a small diameter of blades, but a high rotation speed in your computer, such a PC will make a lot of noise even when performing "office tasks".

Also, when choosing a cooler, you should pay attention to the type of bearing on which the fan is mounted. On sale, you can find options made on rolling bearings (Ball Bearing) or sliding (Slide Bearing). Roller bearings, which are less noisy and have a longer service life, perform better.

How to install a cooler on a processor

Having chosen the right cooler, there should be no problems with its installation. Using special fasteners, the fan is installed over the processor, which is inserted into the slots of the socket. Most often, along with the cooler, there is a detailed instruction for its installation, which allows you to understand in general terms the principle of the fastening mechanism.

Important before installing the cooler. It is necessary to eliminate irregularities between the base of the cooler and the processor for maximum heat transfer. The processor will not be able to work for a long time without thermal paste, therefore it is forbidden to neglect this step.

Choosing a productive CPU cooler

The home personal computer is the element of consumer electronics that you always want to improve at least a little, but to improve. Add RAM, install another hard drive, upgrade the video card and many more "improve", "boost", "expand", etc. One of the simplest (at first glance), effective and inexpensive ways to improve the performance of your computer is overclocking the central processor. In the computer environment, this process is called the beautiful word "overclocking", since in most cases it consists in increasing the frequency at which the processor operates.

One of the side effects of overclocking is a significant increase in the power consumption of the electric current and, as a consequence, an increase in the amount of heat released by the processor. Those who are somewhat familiar with the physics of semiconductors are well aware that the performance of any semiconductor element is highly dependent on temperature. The higher it is, the more unstable the microcircuit works, and when a critical point is reached, the semiconductor turns into a conductor, energy consumption and release increases abruptly and the processor burns out or turns off. On the contrary, the lower the temperature of the silicon crystal, the more stable it works and the higher its performance.

From what has been written it follows that the better the central processor in the system unit of a personal computer is cooled, the higher its speed and more stable operation. The more powerful the cooling system, the more you can overclock the processor, thereby increasing the overall performance of the PC.

Scythe Rasetsu - small and efficient

To cool the processor while the computer is running, a wide range of different devices are produced, the operation of which is based on various principles. We talked about the physics of heat dissipation in detail in the article "Theoretical Foundations of Cooling System Unit Elements. Processor Coolers", so now let's dwell on the practical side of selecting such a cooling system, the performance of which is optimal for your system.

Step one - defining the socket

Central processors of personal computers (like any other components) change quite noticeably with the development of technologies for their production. Moreover, these changes concern not only the improvement of characteristics and changes in the internal structure of the crystal, but also the purely geometric and electrophysical parameters of the chip. The dimensions of the case change, the number, height and shape of the legs, the distance between them and the method of fixing the processor to the motherboard change. All of the above set of parameters together is standardized for each type of processor and is called a processor socket.

Socket FM2 and plastic cooler mounts

There are quite a lot of socket types (there are more than three dozen for Intel processors and almost the same for AMD), and each of them has its own unique mechanical and geometric parameters. Each socket also has its own way of attaching the CPU cooler to the motherboard. Therefore, when choosing a cooling system, you should first of all find out the socket of the processor installed in your system and limit the range of choices to the appropriate type of coolers.

Socket 1150. You can see the mounting holes for mounting the cooler

The choice is somewhat facilitated by the fact that in recent years there has been some unification of the cooler mount for various sockets. This is especially noticeable in motherboards for AMD processors. The mounts have not been modified since the release of socket AM2, and the same cooler can be installed on any modern processor with sockets AM2 +, AM3, AM3 +, FM1, FM2 and FM2 +. For Intel processors, two types of fastening are now relevant - one for LGA2011 and another for LGA1150, LGA1155 and LGA1156. Older processor generations require different mounts.

All manufacturers must indicate the information on the compatibility of the processor cooler with various sockets both on the box and on their website. Many coolers come with several types of mounting, which makes them universal in relation to the socket.

Step two - choosing a manufacturer

The total number of companies producing cooling systems for personal computer processors is very large. Fortunately, there is a certain table of ranks that allows you to divide cooler manufacturers by quality, reliability and efficiency of their products (note that this rating largely reflects the subjective opinion of the author of the article, but at the same time takes into account the average objective data on the test results of various devices named below brands).

Top brands include the Austrian company Noctua, whose coolers are quiet and excellently efficient, the Japanese Skythe, which produces high-performance and original devices, the Taiwanese Thermaltake and Cooler Master, and the South Korean Zalman, without hesitation. Let's make a reservation right away that there is a fairly large number of devices that are excellent in their characteristics from other manufacturers, but it is the high-quality products of these companies in a wide range that are available on the domestic market, so they are preferred.

Step three - determining the required performance

There are several different methods for calculating the required performance of a processor cooler, taking into account the amount of heat dissipated by the processor, the effective dissipation area of \u200b\u200bthe radiator fins, the amount of air flow created by the fan (s) of the cooler, the material of the cooler or heat sink base, and other parameters. Within the framework of this article, we will not delve so much into theory and overload the text with formulas. We will select a sufficiently effective cooler according to the specifications provided by the manufacturer in several steps.

The first step is to determine in which mode your computer will operate. If you are not going to overclock the processor, then the selection process is greatly simplified. It is enough to simply find in the specifications of the cooler the correspondence to your or a more powerful processor of the same type, and you can safely install this cooler into the system. Most modern classic coolers with direct contact between the heatsink and the processor are quite enough to operate in normal modes. In this case, the choice of a specific model must be carried out according to other criteria - low noise level, design, air flow direction, etc.

If the overclocking of the system is not excluded, then the cooling system should be selected more carefully. First, determine how much overclocking you are going to subject your system and what result you want to get in the end. Extreme fans looking to squeeze the best possible (and impossible) out of the best components available on the market and set another performance record for a personal computer, use liquid nitrogen cooling systems as a refrigerant. It makes no sense to write anything in more detail for such enthusiasts in this article, since all of them, as a rule, are very knowledgeable in the technical side of the issue.

System cooling with liquid nitrogen

Everyone else can be recommended a simple algorithm for choosing a cooling system. Those who plan to constantly or most of the time subject the overclocked processor to serious loads (for example, in demanding gaming modes) should pay attention to liquid cooling systems. Now their cost is no longer transcendental, although it exceeds the price of good air coolers. The performance of various LSS varies widely, so it is worth pre-reading the relevant reviews and tests in search of a compromise between efficiency and cost.

LSS can be so large

Those PC owners who overclock the processor to improve the overall system performance and subject it to serious loads only from time to time, it is quite possible to be content with air cooling systems on heat pipes. Evaluation of the cooler efficiency can be carried out by visual indicators:

- the number of heat pipes - the more, the better;

- size and weight of the radiator - large massive radiators with a large number of thin fins are more efficient;

- fan Size and Number - Large diameter fans not only provide more airflow, but are also quieter when cooling an unloaded processor.

Scythe Katana 3 - both the processor cools and the memory blows

Of those coolers that, in your opinion, are suitable for your purposes, the most suitable one can be selected by referring to the test results of various Internet laboratories. Now there are similar tests for almost any cooling system produced by more or less well-known brands.

Step four - determining the compatibility of the cooler with the motherboard and case

Unfortunately, even if the mount of the cooler you like matches the socket of your processor, this does not guarantee its compatibility with your system. The reason for the incompatibility may be a purely geometric discrepancy between the overall parameters of the cooler and the location of the elements of the motherboard, power supply and case walls.

The easiest way is to check the possibility of installing the cooler in the case by its vertical dimensions. To do this, you can simply take a regular ruler and measure the distance along the back wall of your case from the left cover to the hole for the connector panel cover. To the result obtained, add 37.5 mm (the standardized distance to the contact plane of the cooler base) and subtract a couple of millimeters by the thickness of the cover. The result will be the maximum allowable vertical dimension of the processor cooler. Keep in mind that for cooling systems with an overhead fan, you must leave a couple of centimeters between the lid and the end of the cooler, otherwise you will have to cut a ventilation hole in the lid (many cases already have such holes).

High radiators often interfere with the cooler

It is more difficult to find out the compatibility of the bottom of the cooler with the elements located around the processor socket on the motherboard. Most often, the conflict arises with the cooling radiators of voltage stabilizers and with heatsinks installed on the RAM. If you suspect that such a conflict may arise, then purchasing a cooler is best done after directly checking its geometric compatibility. To do this, it is quite possible to take your system unit to the store where you plan to buy a cooling system and perform a trial installation.

Step five - we protect your hearing and nerves

Almost any processor cooler during operation is a source of quite distinguishable noise consisting of the hum of the fan bearings, air noise in the fan blades and radiator planes, the noise of a pump for liquid and air in radiators for LSS. The only absolutely silent option (apart from passive radiators) known to the author is a liquid cooling system based on liquid metal, in which the coolant is pumped by an electromagnetic pump.

Danamics LM10 - cooler with liquid metal as a heat carrier

All other coolers produce noise levels in the range from 15 to 45 dB (A) and more during operation. A sound level of up to 35 dB (A) is comfortable for a person, and a level of up to 22 dB (A) can be considered silent.

Information about the "noise" of any cooler is always given both on its packaging and on the manufacturer's website, so choosing a quiet device is not a problem.

Summary

The modern market for processor cooling systems is so vast and diverse that it is difficult to give a fairly complete description within one article. The material, shape and size of radiators, the material of the sole or the heat sink, the size and power of the fans, the direction of the air flow and other parameters are very different in different devices. But it is precisely this variety that makes it possible to confidently assert that, with some effort, you can always choose exactly the processor cooler that is optimal for your system in terms of price and efficiency.

How to Choose a CPU Cooler | The basics (why more is better)

Any electrical circuit has resistance, and it is the principle of electrical resistance that is embedded in both the CPU and toasters. Electrical semiconductors have the unusual property that they can change resistance from low to high when an electric current is applied in a certain way. These states are represented in the logic diagram as ones and zeros. Although the logic circuits in the CPU are not designed to heat anything, in fact we use small hotplates in computers.

Logic groups get very hot while processing data. Therefore, developers are faced with the task of preventing the melting of small pieces of glass on which these circuits are etched. To do this, they came up with heat sinks in the form of massive metal radiators - these are the key elements of the processor cooling system.

And yet the term "heat sink" means something that absorbs heat. Radiators help to dissipate a large amount of heat into relatively cold air by their fins, which increase the area of \u200b\u200bthe dissipating surface. Thanks to these fins, a standard CPU heatsink turns into a special type of heatsink, if you ignore the terminology. Like most radiators, their main principle of heat transfer is convection (and a little - thermal radiation), this is when heated air rises up, being replaced by cold air from below.

The heat dissipation of a processor depends on its clock speed, voltage, circuit complexity, and the material on which the circuit is engraved. Some low-power processors require low-fins heatsinks to cool some low-power processors, but most desktop users want more performance, resulting in more heat that needs to be dissipated.

When natural convection does not quickly replace warm air with cold air, the process must be accelerated, which is achieved by installing a fan. The photo above shows a rare, all-copper cooler. Copper transfers heat faster than aluminum, but it also weighs more and costs more. To achieve the best price-to-cooling ratio and cooling-to-weight ratio, manufacturers often use a copper bar surrounded by aluminum fins.

Additional fans and increased surface area of \u200b\u200bthe heatsink increase the efficiency of the CPU cooler. Liquid cooling allows you to install huge radiators that are not attached to the motherboard, but to the computer case. A so-called water block is installed on the CPU, which transfers heat to the liquid. The pump is installed on the side of the radiator (as in the photo above) and pumps water (or refrigerant) through the channels of the radiator and water block.

Any of the solutions described above will maximize contact with the circulating air, but they will not work effectively if there is no good contact between the CPU and cooler surfaces. To fill the space between surfaces, use heat-conducting material , it displaces air, which acts as an insulator. Most CPU coolers come with it. In many models, it is immediately applied to the contacting surface. But enthusiasts often opt for third-party heat transfer compounds instead of factory-made materials, although our tests have shown that the difference between them is quite small .

For extreme cooling, refrigerant compressor units are used. Such systems are capable of lowering the CPU temperature well below the ambient temperature. But, as a rule, they use much more power than the processor itself. There are versions that compress and cool air to produce liquid nitrogen. However, serious concerns are caused by condensation around cold components, so even the simplest "refrigerators" are usually used only at exhibitions and competitions.

The bigger is better rule for coolers is limited in this case by the size of your case, but there are several other factors to consider as well. Since this article is written for beginners, we will only consider models from our list of the best cpu coolers ... It includes large air coolers (over 150 mm in height), low-profile coolers (up to 76 mm), medium-sized coolers (76 to 150 mm), and ready-made liquid cooling systems.

How to Choose a CPU Cooler | What about boxed coolers?

"Boxed" or "boxed" coolers are coolers that are supplied by CPU manufacturers with their products. They are usually not designed for increased processor heat dissipation during overclocking or for installation in the limited space of narrow computer cases. The motherboard typically lowers the fan speed to reduce noise and is the first to respond to a rise in CPU temperature by increasing the fan speed to its maximum. If, at maximum fan speed, the cooler is unable to lower the CPU temperature to an acceptable level, the system reduces the clock speed and CPU voltage. We call this process thermal regulation (throttling) or throttling. In the worst case scenario, you can see a picture when a droning computer is not able to provide the required level of performance.

Third-party coolers typically have a larger dissipation surface area, as well as larger fans that allow you to pump more air with less noise. The photo above shows from left to right: a water cooling system with a radiator for two 140mm fans, a large air cooler with two radiators, two generations of stock or boxed Intel coolers, and a wide low-profile cooler designed primarily for HTPC systems.

Included with the FX-8370 processors, AMD provides cooler Wraith , which is another attempt to raise the cooling efficiency of box coolers.

Temperature change during processor heating

Despite the good performance of AMD's new cooler, buyers are sometimes forced to buy third-party coolers as some high-performance CPU models ship without them.

Recently, AMD and Intel have begun to supply compact liquid cooling solutions to meet the cooling requirements of very hot processors, and buyers do not need to turn to alternative brands. The growing popularity of mounts for 120mm fans in modern cases allows small SVOs to be installed in cases of different shapes and sizes, which compares favorably with air coolers of similar dimensions.