Many people know from the school physics course that the current is alternating and constant. If we can say something with confidence about the use of alternating current (all household electrical appliances are powered by alternating current), then we know practically nothing about direct current. But since there are DC networks, then there are consumers, and, accordingly, such networks also need protection. Where DC consumers are found and what is the difference between protection devices for this kind of current, we will consider in this article.

None of the types of electric current are "better" than the other - each is suitable for solving specific problems: alternating current is ideal for generating, transmitting and distributing electricity over long distances, while direct current finds its application in special industrial facilities, installations solar energy, data centers, electrical substations, etc.

DC distribution cabinet for electrical substation

Understanding the differences between AC and DC gives a clear understanding of the challenges faced by DC circuit breakers. The alternating current of industrial frequency (50 Hz) changes its direction in the electric circuit 50 times per second and the same number of times it “crosses” the zero value. This "transition" of the current value through zero contributes to the quickest extinguishing of the electric arc. In DC circuits, the voltage value is constant - just as the direction of the current is constant in time. This fact significantly complicates the extinguishing of the DC arc, and therefore requires special design solutions.

Combined graphs of normal and transient modes when disconnecting: a) alternating current; b) direct current

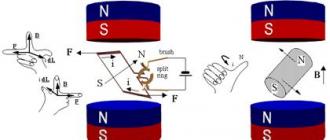

One of such solutions is the use of a permanent magnet (3). The movement of an arc in a magnetic field is one of the methods of extinguishing in devices up to 1 kV and is used in modular circuit breakers. The electric arc, which is inherently a conductor, is affected by a magnetic field, and it is drawn into the arc chute, where it finally dies out.

1 - movable contact

2 - fixed contact

3 - silver-containing contact soldering

4 - magnet

5 - arc chute

6 - bracket

Polarity must be observed

Another and perhaps the key difference between AC and DC circuit breakers is the presence of polarity in the latter.

Connection diagrams for single-pole and double-pole DC circuit breakers

If you protect a single-phase AC network with a two-pole circuit breaker (with two protected poles), then there is no difference in which pole to connect the phase or neutral conductor. When connecting circuit breakers to the DC network, it is necessary to observe the correct polarity. When a single-pole DC switch is connected, the supply voltage is supplied to terminal "1", and when a two-pole switch is connected, to terminals "1" and "4".

Why is this so important? See video ... The author of the video conducts several tests with a 10-amp breaker:

- Plugging in the circuit breaker with the correct polarity - nothing happens.

- The switch is installed in the network with reverse polarity; network parameters U \u003d 376 V, I \u003d 7.5 A. As a result: strong smoke emission followed by ignition of the switch.

- The switch is installed with the correct polarity, and the current in the circuit is 40 A, which is 4 times its rating. The thermal protection, as it should be, opened the protected circuit after a few seconds.

- The last and most severe test was carried out with the same 4-fold overcurrent and reverse polarity. The result was not long in coming - instant ignition.

Thus, DC circuit breakers are protection devices used for objects of alternative energy, automation and control systems of industrial processes, etc. Special versions of protective characteristics Z, L, K allow you to protect high-tech equipment of industrial enterprises.

Content:In all electrical networks, a large number of devices are used, the main function of which is to protect lines and equipment from overcurrent and short circuits. Among them, a network protection circuit breaker has become widespread, which performs not only protection, but also circuit switching. Thus, the circuit breakers provide the switching on and off of specific areas, protect them from overcurrent by disconnecting the protected circuits in the event of emergency situations.

Types of electrical machines

Circuit breakers are widely used in power supply systems, providing reliable protection for electrical circuits and networks, household appliances and electrical equipment. Their main task is to de-energize the circuit at the right time by turning off the supply of electric current. The circuit breaker is triggered during short circuits, as well as when the wires are heated due to overloads in the network.

Circuit breakers can operate in DC and AC circuits, and universal designs can operate in the presence of any electric current in the network. According to their design, they are divided into three types, which serve as the basis for other types of circuit breakers:

- Air machines. They are used in industrial production, where currents in circuits can reach several thousand amperes.

- Molded case machines. They have a wide operating range, ranging from 16 to 1000 A.

- Modular machines. They are widely used in apartments and private houses. Their name is associated with the standard width of 17.5 mm, depending on the number of poles. That is, several switches can be used in one unit at once.

All circuit breakers are divided according to the rated current and voltage, since most of the protective devices are installed in 220 or 380V networks.

Circuit breakers can be current-limiting and non-current limiting. In the first case, the circuit breaker is a switch in which the tripping time is set to an extremely small value, during which the short-circuit currents do not have time to reach their maximum.

The machines are classified by the number of poles and can be one-, two-, three- and four-pole. They are equipped with overvoltage releases, undervoltage releases, undervoltage releases. The speed of response is of great importance when devices can be normal, fast-acting and selective. Some devices allow a combination of specifications. Some models are equipped with free contacts, and the conductors are connected to them in different ways.

There is a division into different types according to the design of the release or circuit breaker installed in the machine. These elements play an important role and are classified as magnetic and thermal. In the first case, the breaker is fast-acting and provides short-circuit protection. The response time is 0.005 to 3-4 seconds. The thermal release is much slower, so it is mainly used for overload protection. The element is based on a bimetallic plate that heats up with increasing loads. The response period ranges from 3-4 seconds to several minutes.

In addition, the machines are divided by type of shutdown or by. Each type A, B, C, D, K, Z. For example, type A is used when opening circuits with a significant length of wiring, it protects semiconductor devices well. The pickup limit is 2-3 rated currents. Type B is used in general lighting systems and has a trip threshold of 3-5 rated currents. More detailed information about each type of machine can be found in the table.

Types of circuit breaker releases

All releases used in circuit breakers can be conventionally divided into two groups. The first group includes devices that protect electrical circuits and are able to recognize the onset of a critical situation when overcurrents appear. As a result of triggering, further development of the accident is suppressed due to the divergence of the main working contacts.

The second group of releases is represented by additional devices that are not included in the basic equipment of the machines. The following can be installed on request:

- Shunt trip units capable of remotely tripping circuit breakers when a signal is received from the auxiliary circuit.

- Undervoltage release. It turns off the machine in the event of a voltage drop below the permissible limits.

- Zero voltage release. Its contacts open when a significant voltage drop occurs.

Thermal release

The sample of the thermal release shown in the figure is made in the form of a bimetallic plate. During the heating process, it bends, changes shape and affects the release mechanism. For the manufacture of the plate, two metal strips are mechanically interconnected. The material of each tape has a different coefficient of thermal expansion. The connection is made by soldering, welding or riveting. The bending of the plate is formed by different changes in length during heating. Thermal releases provide overcurrent protection and can be set to a predetermined trip mode.

The main advantage of the thermal release is its high vibration resistance, the absence of rubbing parts and the ability to work in a dirty form. They are distinguished by their simplicity of design and low cost. As disadvantages, it should be noted the constant consumption of electricity, sensitivity to temperature extremes, the possibility of false alarms when heated by extraneous sources.

The same widespread use was received by electromagnetic releases with instantaneous action. Structurally, they are made in the form of a solenoid with a core acting on the release mechanism. When an overcurrent flows through the solenoid coil, it creates a magnetic field that moves the core and simultaneously overcomes the resistance of the return spring.

The electromagnetic release is set to operate in the event of a short circuit, the value of which is 2-20 ln. In turn, the value ln \u003d 200 A. The setting error can be 20% in one direction or another of the set value. Therefore, the pickup settings for power circuit-breakers are indicated in amperes or in multiples of the rated current. Modular circuit breakers have protective characteristics, denoted B (3-5), C (5-10) and D (10-50), where the digital values \u200b\u200bcorrespond to the maximum rated current ln, at which the contact diverges.

Electromagnetic release

The main advantages of electromagnetic releases are resistance to vibration, shock and other mechanical influences, as well as simplicity of design, which facilitates the repair and maintenance of the device. The disadvantages include instantaneous response, without time delays, as well as the creation of a magnetic field during operation.

The time delay is of great importance as it provides selectivity. In the presence of selectivity or selectivity, the input automaton recognizes the presence of a short circuit, but it is skipped for a certain set time. During this time interval, the downstream protective device must have time to trigger, not shutting off the entire object, but only the damaged area.

Quite often, thermal and electromagnetic releases are used together, by connecting both elements in series. Such a bundle is called a combined or thermomagnetic release.

Semiconductor release

More complex devices include semiconductor releases. Each of them includes a control unit, measuring transformers for alternating current or magnetic amplifiers for direct current, as well as an operating electromagnet that acts as a shunt release. With the help of the control unit, a user-defined program is set, under the guidance of which the main contacts will be disconnected.

During the settings, the following actions are performed:

- The rated current of the machine is regulated

- The time delay in the overload and short circuit zones is adjustable.

- The short-circuit pickup setting is determined.

- Setting the safety switches to operate from a single-phase connection.

- Setting the switch to turn off the time delay when a short circuit changes the selectivity mode to snap action.

Electronic release

The design of the electronic trip unit resembles that of a similar semiconductor device. It also consists of an electromagnet, measuring devices and a control unit. The value of the operating current and the holding time are set in steps, providing guaranteed operation in case of short circuit and inrush currents.

The advantages of these devices are a variety of settings and the ability to choose, the operation of the installed program with high accuracy, the presence of indicators of operability and the reasons for operation, logical selective communication with switches located above and below the machine.

The disadvantages include the high price, the fragility of the control unit and sensitivity to the influence of electromagnetic fields.

DC circuit breakers are used to disconnect the circuit under load. At traction substations, switches are used to turn off 600 V supply lines during overloads and short-circuit currents and to turn off the reverse current of rectifier units during reverse ignition or breakdown of valves (i.e., internal short circuits during parallel operation of units).

Electric arc extinguishing by automatic switches occurs in the air on arcing horns. Arc lengthening can be done using magnetic blast or in chambers with narrow slits.

In all cases of disconnection of the circuit and the formation of an electric arc, a natural upward movement of the arc occurs together with the movement of the air heated by it, i.e., thermal blast.

Mainly applied high-speed circuit breakers.

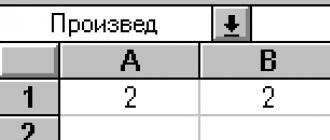

Figure: 1. Oscillograms of current and voltage when the short-circuit current is turned off: a - by a non-fast switch, b - by a high-speed switch

The total time T of breaking the short-circuit or overload current by the circuit breaker consists of three main parts (Fig. 1):

T \u003d t о + t 1 + t 2

where t0 is the rise time of the current in the circuit to be disconnected to the value of the setting current, i.e. to the value at which the disconnecting device of the circuit breaker is triggered; t1 - own breaker opening time, i.e. the time from the moment of reaching the setting current until the moment when the breaker contacts begin to diverge; t2 - arc burning time.

The rise time of the current in the circuit t0 depends on the circuit parameters and the switch setting.

The intrinsic tripping time t1 depends on the type of switch: for non-high-speed switches, the intrinsic tripping time is within 0.1-0.2 s, for high-speed ones - 0.0015-0.005 sec.

The arcing time t2 depends on the value of the current to be switched off and the characteristics of the circuit breaker arcing devices.

The total shutdown time of the non-high-speed circuit breaker is within 0.15-0.3 sec, the high-speed one is 0.01-0.03 sec.

Due to its short inherent tripping time, the high-speed circuit breaker limits the maximum short-circuit current in the protected circuit.

Traction substations use high-speed automatic DC switches: VAB-2, AB-2/4, VAT-43, VAB-20, VAB-20M, VAB-28, VAB-36 and others.

Switch VAB-2 is polarized, that is, it reacts to current in only one direction - forward or reverse, depending on the setting of the switch.

In fig. 2 shows the electromagnetic mechanism of the DC switch.

Figure: 2. Electromagnetic mechanism of the VAB-2 circuit breaker: a - cut-off of the circuit breaker, b - limit wear of the contacts of the VAB-2 circuit breaker, (A - the minimum thickness of the fixed contact is 6 mm, B - the minimum thickness of the moving contact is 16 mm); 1 - holding coil, 2- magnetic circuit, 3-switching coil, 4 - magnetic armature, 5 - upper steel bar, 6 - anchor, 7 - main coil, 8 - calibration coil, 9 - U-shaped magnetic circuit, 10 - current carrying output, 11 - adjusting screw, 12 - shunt plate, 13 - flexible connection, 14 - stop, 15 - armature lever, 16 - armature lever axis, 17 - fixed contact, 18 - movable contact, 19 - contact lever, 20 - axis contact lever, 21 - axle with roller, 22 - locking lever, 23 - shut-off springs, 24 - rod, 25 - adjusting screws, 26 - bracket, 27 - holding coil core

The armature lever 15 (Fig. 2, a) rotates around the axis 16 passed through the upper steel bar 5. In the lower part of the lever 15, which consists of two silumin cheeks, the steel anchor 6 is clamped, and in the upper part there is a spacer sleeve with the axis 20, around which the contact lever 19 rotates, made of a set of duralumin plates.

A movable contact 18 is fixed in the upper part of the contact lever, and a copper shoe with a flexible link 13 is fixed at the bottom, with the help of which the movable contact is connected to the main current coil 7 and through it to terminal 10. To the lower part of the contact lever, stops 14 are attached on both sides, and on the right side there is a steel axle with a roller 21, to which two shut-off springs 23 are attached on one side.

In the off position, the system of levers (armature lever and contact lever) is turned by shut-off springs 23 around axis 16 until the armature 6 stops in the left rod of the U-shaped magnetic circuit.

The closing 3 and holding 1 coils of the circuit breaker are powered from their own DC needs.

To turn on the switch, you must first close the circuit of the holding coil 1, then the circuit of the closing coil 3. The direction of the current in both coils should be such that the magnetic fluxes generated by them add up in the right core of the magnetic circuit 9, which serves as the core of the closing coil; then the armature 6 will be attracted to the core of the closing coil, ie, will be in the "On" position. In this case, the axis 20 together with the contact lever 19 will rotate to the left, the disconnecting springs 23 will stretch and will tend to rotate the contact lever 19 around the axis 20.

When the switch is turned off, the magnetic armature 4 lies on the end face of the closing coil and, when the switch is turned on, remains attracted to the end of the core by the total magnetic flux of the closing and holding coils. The magnetic armature 4 by means of a rod 24 is connected to the locking lever 22, which does not allow the contact lever to rotate to the stop of the movable contact into the fixed one. Therefore, a gap remains between the main contacts, which can be adjusted by changing the length of the rod 24 and should be equal to 1.5-4 mm.

If the voltage is removed from the closing coil, then the electromagnetic forces holding the armature 4 in the attracted position will decrease and the springs 23 with the help of the locking lever 22 and the rod 24 will tear the armature from the end of the core of the closing coil and rotate the contact lever until the main contacts are closed. Therefore, the main contacts will only close after the closing coil has been opened.

Thus, the principle of free tripping is realized for VAB-2 circuit breakers. The gap between the magnetic armature 4 (otherwise called the free trip armature) and the end of the closing coil core in the closed position of the switch should be within 1.5-4 mm.

The control circuit provides for the supply of a short-term current pulse to the closing coil, the duration of which is sufficient only to have time to move the armature to the "On" position. After that, the closing coil circuit is automatically opened.

The presence of a free trip can be checked in the following way. A piece of paper is placed between the main contacts and the contact of the contactor is closed. The circuit breaker is closed, but while the contactor contact is closed, the main contacts should not close and the paper can be freely removed from the gap between the contacts. As soon as the contactor contact is open, the magnetic armature will be torn off from the end of the closing coil and the main contacts closed. In this case, the piece of paper will be squeezed between the contacts and it will not be possible to remove it.

When the switch is turned on, a characteristic double blow is heard: the first is from the collision of the armature and the core of the closing coil, the second is from the collision of the closed main contacts.

The polarization of the switch consists in choosing the direction of the current in the holding coil, depending on the direction of the current in the main current coil.

In order for the switch to turn off the circuit when the direction of the current in it changes, the direction of the current in the holding coil is selected so that the magnetic fluxes created by the holding coil and the main current coil coincide in the direction in the core of the closing coil. Therefore, when the current flows in the forward direction, the main circuit current will help keep the breaker in the closed position.

In emergency mode, when the direction of the main current is reversed, the direction of the magnetic flux created by the main current coil in the core of the closing coil will change, i.e. the magnetic flux of the main current coil will be directed against the magnetic flux of the holding coil and at a certain value of the main current the core of the closing coil will be demagnetized and the opening springs will open the circuit breaker. The speed is determined to a greater extent by the fact that while the magnetic flux decreases in the core of the switching coil, the magnetic flux increases in the core of the main current coil.

In order for the switch to turn off the circuit when the current rises above the setting current in the forward direction, the direction of the current in the holding coil is selected so that the magnetic flux of the holding coil in the core of the closing coil is directed against the magnetic flux of the main current coil when the forward current flows through it. In this case, with an increase in the main current, the demagnetization of the closing coil core increases, and at a certain value of the main current, equal to or higher than the setting current, the breaker is opened.

The setting current in both cases is regulated by changing the holding coil current value and by changing the gap δ1.

The magnitude of the holding coil current is regulated by changing the magnitude of the additional resistance connected in series with the coil.

Changing the gap δ1 changes the magnetic flux resistance of the main current coil. With a decrease in the gap δ1, the magnetic resistance decreases and, consequently, the magnitude of the breaking current decreases. The gap δ1 is changed using the adjusting screw 11.

The gap δ2 between the stops 14 and the cheeks of the armature lever 15 in the on position of the switch characterizes the quality of the closure of the main contacts and should be within 2-5 mm. The plant produces switches with a gap δ2 equal to 4-5 mm. The size of the gap δ2 determines the angle of rotation of the contact lever 19 about the axis 20.

The absence of a gap δ2 (the stops 14 are in contact with the cheeks of the armature lever 15) indicates poor contact or lack of contact between the main contacts. A gap δ2 less than 2 mm or more than 5 mm indicates that the main contacts are in contact only at the bottom or top edge. The gap δ2 can be small due to the high wear of the contacts, which in this case are replaced.

If the dimensions of the contacts are sufficient, then the gap δ2 is adjusted by moving the entire switching mechanism along the circuit breaker frame. To move the mechanism, two bolts are released that secure the mechanism to the frame.

The distance between the main contacts in the open position should be 18-22 mm. Pressing the main contacts for switches for rated current up to 2000 A inclusive should be in the range of 20-26 kg, and for switches for rated current 3000 A - within 26-30 kg.

In fig. 2, b shows the movable system of the switch with the designation of the limit of contact wear. The movable contact is considered worn out when dimension B becomes less than 16 mm, and the fixed contact when dimension A becomes less than 6 mm.

In fig. 3 shows a detailed control scheme for the VAB-2 circuit breaker. The circuit provides for the supply of a short-term pulse to the closing coil and does not allow multiple repeated switching on when the power button is pressed for a long time, ie it protects against "ringing". The holding coil is constantly being charged with current.

To turn on the switch, press the "On" button, thus closing the circuit of the coils of the contactor K and the blocking RB. In this case, only the contactor is activated, which closes the circuit of the VK closing coil.

As soon as the armature takes the “On” position, the closing auxiliary contacts of the circuit breaker BA will close, and the disconnecting contacts open. One of the auxiliary contacts bypasses the coil of contactor K, which will break the circuit of the closing coil. In this case, all the mains voltage will be applied to the coil of the RB blocking relay, which, having triggered, shunts the contactor coil again with its contacts.

To close the switch again, open the power button and close it again.

The discharge resistance CP, connected in parallel with the holding coil of the DC, serves to reduce the overvoltage when the coil circuit is opened. Adjustable LED resistance provides the ability to change the holding coil current.

The rated current of the holding coil at 110 V is 0.5 A, and the rated current of the closing coil at the same voltage and parallel connection of both sections is 80 A.

Figure: 3. Electrical circuit for VAB-2 circuit breaker control: Off. - shutdown button, DC - holding coil, LED - additional resistance, CP - discharge resistance, BA - switch auxiliary contacts, LK, LZ - red and green signal lamps, Incl. - ON button, K - contactor and its contact, RB - blocking relay and its contact, VK - closing coil, AP - automatic switch

Voltage fluctuations of operating circuits from - 20% to + 10% of the rated voltage are permissible.

The total disconnection time of the circuit by the VAB-2 switch is 0.02-0.04 sec.

The extinguishing of the arc when the circuit breaker breaks the circuit under load occurs in the arc chute with the help of magnetic blast.

The magnetic blowing coil is usually connected in series with the main fixed contact of the switch and is a turn of the main current-carrying bus, inside which there is a core made of steel tape. To concentrate the magnetic field in the arc formation zone at the contacts, the magnetic blast coil core at the switches has pole pieces.

The arc extinguishing chamber (Fig. 4) is a flat box made of asbestos cement, inside of which two longitudinal partitions are made 4. Horn 1 is installed in the chamber, inside which the axis of rotation of the chamber passes. This horn is electrically connected to the moving contact. Another horn 7 is fixed on a fixed contact. To ensure a quick transition of the arc from the movable contact to horn 1, the distance of the horn from the contact should be no more than 2-3 mm.

The electric arc arising when disconnected between contacts 2 and 6 under the action of a strong magnetic field of the magnetic blowing coil 5 is quickly blown onto horns 1 and 7, lengthens, is cooled by the counterflow of air and the walls of the chamber in narrow slots between the partitions and quickly extinguishes. It is recommended to insert ceramic tiles into the walls of the chamber in the arc-extinguishing zone.

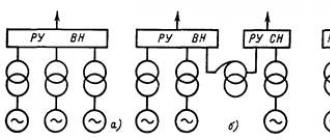

Arc extinguishing chambers for circuit breakers for voltages of 1500 V and above (Fig. 5) differ from the chambers for voltages 600 V in large dimensions and the presence of holes in the outer walls for the outlet of gases and an additional magnetic blast device.

Figure: 4. Arc extinguishing chamber of VAB-2 circuit breaker for voltage 600 V: 1 and 7 - horns, 2 - movable contact, 3 - outer walls, 4 - longitudinal partitions, 5 - magnetic blast coil, 6 - fixed contact

Figure: 5. Arc extinguishing chamber of VAB-2 circuit breaker for voltage 1500 V: a - chamber device, b - arc extinguishing circuit with additional magnetic blow; 1 - movable contact, 2 - fixed contact, 3 - magnetic blast coil, 4 AND 8 - horns, 5 and 6 - auxiliary horns, 7 - auxiliary magnetic blast coil, I, II, III, IV - position of the arc during extinguishing

The additional magnetic blast device consists of two auxiliary horns 5 and 6, between which the coil 7 is connected. As the arc lengthens, it begins to close through the auxiliary horns and the coil, which, due to the current flowing through it, creates an additional magnetic blast. All chambers have metal pole plates on the outside.

For fast and stable extinction of the arc, the divergence of the contacts should be at least 4-5 mm.

The body of the switch is made of a non-magnetic material - silumin - and is connected to a moving contact, therefore, during operation it is under full operating voltage.

Automatic high-speed DC switch BAT-42

Operation of DC Circuit Breakers

In operation, it is necessary to monitor the state of the main contacts. The voltage drop between them at rated load should be within 30 mV.

Oxide is removed from the contacts with a wire brush (brushing). When sags appear, they are removed with a file, however, the contacts should not be filed to restore their original flat shape, as this leads to their rapid wear.

It is necessary to periodically clean the walls of the arc-extinguishing chamber from copper and coal deposits.

When revising a DC switch, the insulation of the holding and closing coils is checked in relation to the case, as well as the insulation resistance of the walls of the arc extinguishing chamber. The insulation of the arc chamber is checked by applying voltage between the main moving and fixed contacts with the chamber closed.

Before putting the switch into operation after repair or long-term storage, the chamber must be dried for 10-12 hours at a temperature of 100-110 ° C.

After drying, the chamber is installed on the switch and the insulation resistance is measured between the two points of the chamber located opposite the movable and fixed contacts when they are open. This resistance must be at least 20 ohms.

The breaker settings are calibrated in the laboratory with a current obtained from a low-voltage generator with a nominal voltage of 6-12 V.

At the substation, the circuit breakers are calibrated with a load current or using a load rheostat at a rated voltage of 600 V. A method of calibrating DC switches can be recommended using a calibration coil of 300 turns of PEL wire with a diameter of 0.6 mm, mounted on the core of the main current coil. Passing a direct current through the coil, the value of the current setting is set according to the number of ampere turns at the moment the switch is turned off. The switches of the first version, which were produced earlier, differ from the switches of the second version by the presence of an oil damper.

Modular DC circuit breakers, or, more simply, automatic machines, are used in power grids and electrical installations, telecommunication cabinets, automation panels. Why are they called modular? The thing is that they are available in standard compact housings and are single-pole modules, of which single-pole, two-pole or three-pole devices can be composed. According to the existing standard, the width of one such pole is 17.5 mm.

A DC circuit breaker differs from a conventional circuit breaker in that it automatically breaks the circuit in the event of a short circuit or overload. The design of the device includes several main elements:

Modern circuit breakers contain two releases (protection devices):

From the foregoing, it follows that DC switches are capable of solving the following tasks:

Note that a DC machine differs from an AC analog primarily in that it has polarity. This must be taken into account when connecting it.

Main advantages

Circuit breakers are widely used due to a number of advantages:

In addition, DC circuit breakers are available in a variety of current ratings from 6 A to 125 A, making them suitable for any equipment and power grid.

Important characteristics

Circuit breakers for DC operation have the following main characteristics:

As we said above, the letter designation is used for the time-current characteristic:

Thus, in order to ensure network protection, when choosing a circuit breaker, it is necessary to select its characteristics in accordance with the characteristics of the equipment and cables.

Why you should buy from our store

In the ATLANT SNAB store you can pick up a DC automatic machine with any characteristics you are interested in. But, this is not the only reason why you should buy a switch from us:

To buy DC switches right now, make a purchase on the website or just call our contact number. By contacting us at least once, you will surely become our regular customer!

From the very beginning of the emergence of electricity, engineers began to think about the safety of electrical networks and devices from current overloads. As a result, many different devices have been designed, which are distinguished by reliable and high-quality protection. One of the latest developments is electrical machines.

This device is called automatic due to the fact that it is equipped with the function of turning off the power in automatic mode, in the event of short circuits, overloads. After tripping, conventional fuses must be replaced with new ones, and the circuit breakers, after eliminating the causes of the accident, can be turned on again.

Such a protective device is necessary in any electrical circuit. The circuit breaker will protect a building or room from various emergencies:

- Fires.

- Electric shocks to a person.

- Wiring faults.

Types and design features

You need to know information about the existing types of circuit breakers in order to select the right device at the time of purchase. There is a classification of electrical machines according to several parameters.

Breaking capacity

This property determines the short-circuit current at which the machine will open the circuit, thereby disconnecting the network and devices that were connected to the network. By this property, automata are subdivided:

- Automatic machines for 4500 amperes are used to prevent malfunctions of power lines of old residential buildings.

- At 6000 amperes, they are used to prevent accidents in case of short circuits in the network of houses in new buildings.

- 10,000 amperes, used in industry to protect electrical installations. A current of this magnitude can be generated in the immediate vicinity of the substation.

The tripping of the circuit breaker occurs during short circuits accompanied by the occurrence of a certain current value.

The machine protects the electrical wiring from damage to the insulation with high current.

Number of poles

This property tells us about the largest number of wires that can be connected to the machine to provide protection. In case of an emergency, the voltage at these poles is cut off.

Features of machines with one pole

Such electrical machines are the simplest in design, and serve to protect individual sections of the network. Two wires can be connected to such a circuit breaker: input and output.

The task of such devices is to protect electrical wiring from overloads and short-circuit wires. The neutral wire is connected to the zero bus, bypassing the machine. Grounding is connected separately.

Automatic machines with one pole are not input, since when it is turned off, the phase is broken, and the neutral wire still remains connected to the power supply. This does not provide 100% protection.

Properties of machines with two poles

In cases where an emergency requires complete disconnection from the electrical network, circuit breakers with two poles are used. They are used as introductory information. In emergency cases, or in the event of a short circuit, all electrical wiring is disconnected at the same time. This makes it possible to carry out repair and maintenance work, as well as work on connecting equipment, since complete safety is guaranteed.

Two-pole electrical machines are used when a separate switch is required for a device operating from a 220 volt network.

An automatic machine with two poles is connected to the device using four wires. Of these, two come from the power supply, and the other two come from it.

Three-pole electrical machines

In an electrical network that has three phases, 3-pole circuit breakers are used. The grounding is left unprotected, and the phase conductors are connected to the poles.

A three-pole circuit breaker serves as an input device for any three-phase load consumers. Most often, this version of the machine is used in industrial conditions to supply electricity to electric motors.

You can connect 6 conductors to the machine, three of which are the phases of the electrical network, and the other three are coming from the machine and are protected.

Using a four-pole circuit breaker

To provide protection for a three-phase network with a four-wire system of conductors (for example, an electric motor connected in a "star" circuit), a 4-pole circuit breaker is used. It acts as an input device for a four-wire network.

It is possible to connect eight conductors to the device. On the one hand - three phases and zero, on the other hand - the output of three phases with zero.

Time-current characteristic

When the power consuming devices and the electrical grid are operating normally, current flows normally. This phenomenon also applies to an electric machine. But, in the case of an increase in the current strength for various reasons above the nominal value, the release of the machine is triggered, and the circuit is broken.

The parameter of this operation is called the time-current characteristic of the electrical machine. It is the dependence of the operation time of the machine and the ratio between the real current passing through the machine and the nominal current value.

The importance of this characteristic lies in the fact that the least number of false alarms is ensured on the one hand, and the current protection is carried out on the other hand.

In the energy industry, there are situations when a short-term increase in current is not associated with an accident, and the protection should not trip. It also happens with electrical machines.

Time-current characteristics determine after what time the protection will operate, and what parameters of the current intensity will arise in this case. The greater the overload, the faster the machine will work.

Electrical machines marked "B"

Automatic switches of category "B" are capable of switching off in 5 - 20 s. In this case, the current value is from 3 to 5 rated current values \u200b\u200b≅0.02 s. Such machines are used to protect household devices, as well as all electrical wiring in apartments and houses.

Properties of machines marked "C"

Electrical machines of this category can turn off in a time of 1 - 10 s, at 5 - 10 times the current load с0.02 s. These are used in many areas, the most popular for houses, apartments and other premises.

The meaning of the marking "D "on the machine

With this class, the machines are used in industry and are made in the form of 3-pole and 4-pole versions. They are used to protect powerful electric motors and various three-phase devices. Their response time is up to 10 seconds, while the response current can exceed the nominal value by 14 times. This makes it possible to use it with the necessary effect to protect various circuits.

Electric motors with significant power are most often connected through electrical machines with a "D" characteristic, because high starting current.

Rated current

There are 12 versions of automatic machines, which differ in the characteristic of the rated operating current, from 1 to 63 amperes. This parameter determines the speed at which the machine turns off when the current limit is reached.

The machine for this property is chosen taking into account the cross-section of the wires of the wires, the permissible current.

The principle of operation of electrical machines

Normal mode

During normal operation of the machine, the control lever is cocked, the current flows through the power wire at the top terminal. Further, the current goes to the stationary contact, through it to the moving contact and along the flexible wire to the solenoid coil. After it, the current goes through the wire to the bimetallic plate of the release. From it, the current passes to the lower terminal and further to the load.

Overload mode

This mode occurs when the rated current of the machine is exceeded. The bimetallic plate is heated with a high current, bends and opens the circuit. The action of the plate takes time, which depends on the value of the passing current.

The circuit breaker is an analog device. There are certain difficulties in setting it up. The tripping current of the release is set at the factory with a special adjusting screw. After the plate has cooled down, the machine can work again. The temperature of the bimetallic plate depends on the environment.

The release does not act immediately, allowing the current to return to its rated value. If the current does not decrease, the release will trip. Overload can occur due to powerful devices on the line, or the connection of several devices at once.

Short circuit mode

In this mode, the current rises very quickly. The magnetic field in the solenoid coil moves the core that actuates the release and disconnects the power supply contacts, thereby removing the emergency load of the circuit and protecting the network from possible fire and destruction.

The electromagnetic release is instantaneous, which differs from the thermal release. When the contacts of the working circuit are opened, an electric arc appears, the magnitude of which depends on the current in the circuit. It causes destruction of contacts. To prevent this negative effect, an arc chute is made, which consists of parallel plates. In it, the arc fades and disappears. The resulting gases are discharged into a special opening.